Special optical glass with pure red luminous properties and its preparation method and application

A technology of optical glass and luminescence characteristics, applied in glass manufacturing equipment, glass furnace equipment, phototherapy and other directions, can solve the problems of increasing the difficulty of preparation and increasing scattering loss, avoiding scattering loss, reducing melting temperature and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the special optical glass with pure red light emitting characteristics of the invention comprises the following steps:

[0052] (1) high purity (99.99%) silica (SiO 2 ), zinc fluoride (ZnF 2 ), zinc chloride (ZnCl 2 ), manganese fluoride (MnF 2 ), lithium fluoride (LiF), silicon nitride (Si 3 N 4 ) and high purity (99.99%) rare earth fluoride as raw materials to prepare glass mixture according to stoichiometric ratio;

[0053] (2) putting the raw materials weighed according to calculation in an agate jar, uniformly mixing them in a ball mill for 30-120min, and transferring the uniformly mixed raw materials into a Shi Ying crucible;

[0054] (3) Put the evenly mixed raw materials into a high-temperature furnace, melt them in the air atmosphere at 1200-1300℃ for 0.5-1.0h, and then pour the melt on the copper plate heated at 200℃ in advance for quenching, thus forming the substrate glass.

[0055] (4) Put the prepared glass in a precision annealing fu...

Embodiment 1

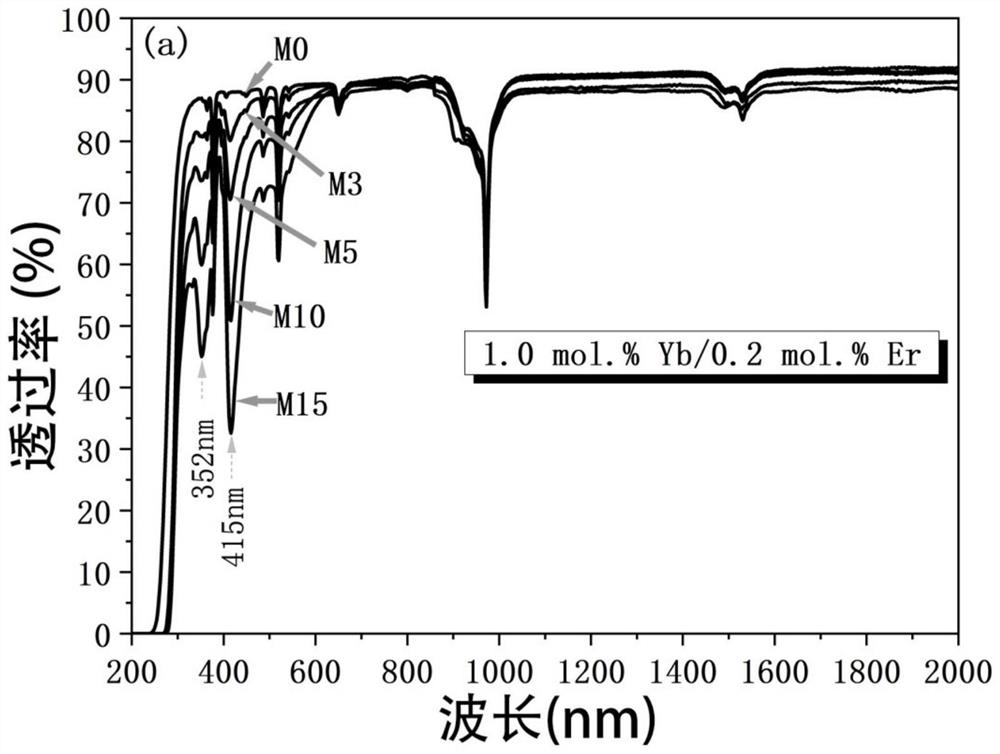

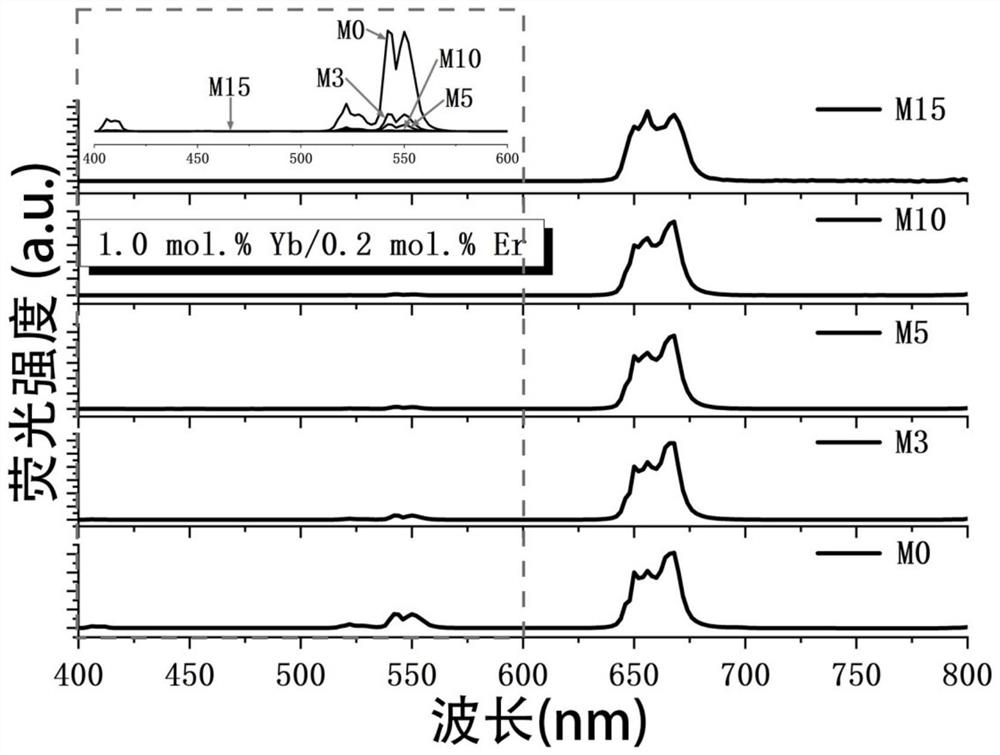

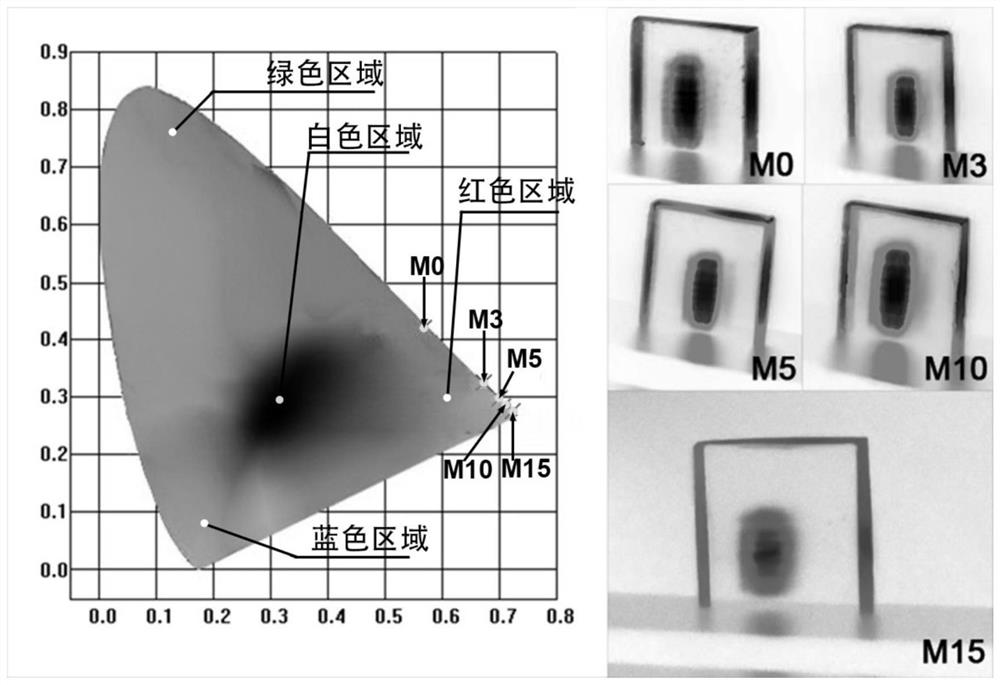

[0063] Example 1: 50 SiO 2 -15ZnF 2 -10ZnCl 2 -15LiF-xMnF 2 -1Si 3 N 4 -1YbF 3 -0.2ErF 3 Preparation of (x = 0-15, mol.%) fluorosilicate multicomponent glass

[0064] In the glass composition of this embodiment, SiO 2 、ZnF 2 、ZnCl 2 、LiF、MnF 2 As the glass matrix, the value before each compound represents the molar ratio (mol.%); Si 3 N 4 YbF, as an externally doped reducing agent, is 3 And ErF. 3 Is an externally doped rare earth ion, and the previous value represents the mole percentage of the doped rare earth ion relative to the whole glass matrix.

[0065] Specific preparation method: respectively weigh SiO according to the measured mass. 2 ,ZnF 2 ,ZnCl 2 ,LiF,MnF 2 ,Si3 N 4 And YbF 3 And ErF. 3 , put the above raw materials in agate jar and stir for 120min with ball mill to make them uniform. Transfer the evenly mixed raw materials to a Shi Ying crucible. Raise the temperature of the high-temperature furnace to 1300℃, and then put the Shi Ying crucible with cover containing r...

Embodiment 2

[0067] Example 2: 45 SiO 2 -15ZnF 2 -10ZnCl 2 -15LiF-xMnF 2 -1Si 3 N 4 -1YbF 3 -0.2HoF 3 Preparation of (x = 0,10,15, mol.%) fluorosilicate multicomponent glass

[0068] In the glass composition of this embodiment, SiO 2 、ZnF 2 、ZnCl 2 、LiF、MnF 2 As the glass matrix, the value before each compound represents the molar ratio (mol.%); Si 3 N 4 YbF, as an externally doped reducing agent, is 3 And HoF 3 Is an externally doped rare earth ion, and the previous value represents the mole percentage of the doped rare earth ion relative to the whole glass matrix.

[0069] Specific preparation method: respectively weigh SiO according to the measured mass. 2 ,ZnF 2 ,ZnCl 2 ,LiF,MnF 2 , Si3N4 and YbF 3 And HoF 3 , put the above raw materials in agate jar, and stir with ball mill for 60min to make them uniform. Transfer the evenly mixed raw materials to a Shi Ying crucible. Raise the temperature of the high-temperature furnace to 1250℃, then put the Shi Ying crucible with cover containing raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com