Method for desulfurization and sulfur recycling of tail gas produced in low-temperature methanol washing process

A low-temperature methanol washing, process tail gas technology, applied in the field of environmental engineering, can solve the problems of unmentioned desulfurization agent regeneration, high investment and operating costs, inability to realize sulfur resources, etc., and achieves a high degree of automation, low safety risk, The effect of eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

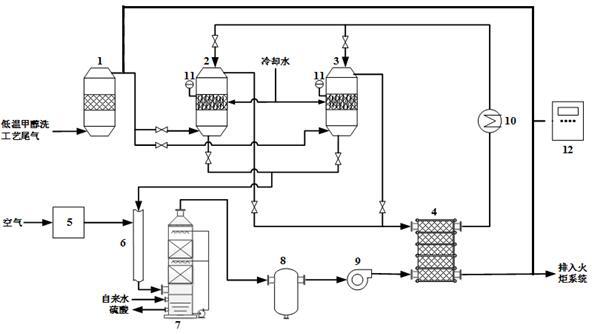

[0049] Embodiment 1: as figure 1 As shown, the method of tail gas desulfurization and sulfur resource utilization in this low-temperature methanol washing process is as follows:

[0050] A low temperature methanol washing system H 2 Exhaust gas at the outlet of the S concentration tower, with an air volume of 50,000m 3 / h, temperature 15°C; main component is CO 2 87%, CO 0.7%, N 2 9%, CH 4 Accounting for 1.3%, C 2 h 6 0.8%, methanol 0.2%, water content about 30g / m 3 . The sulfide in the exhaust gas is mainly H 2 S and COS, the concentrations are 30ppm and 150ppm, the rest are like CS 2 The total concentration of organic sulfur is less than 1mg / m 3 ;

[0051] (1) Organic sulfur conversion: H 2 The tail gas at the outlet of the S concentration tower first enters the organic sulfur conversion tower 1, and the reaction space velocity is 3000h -1 , under the condition of 80 ℃, using Danish Topsoe CKA catalyst, COS undergoes the following hydrolysis reaction:

[0052] ...

Embodiment 2

[0059] Embodiment 2: as figure 1 As shown, the method of tail gas desulfurization and sulfur resource utilization in this low-temperature methanol washing process is as follows:

[0060] A low temperature methanol washing system CO 2 Tail gas at the outlet of the flash tower, with an air volume of 20,000m 3 / h, temperature 20℃; main component is CO 2 95%, CO 0.6%, N 2 0.15%, CH 4 Accounting for 2%, C 2 h 6 1.3%, methanol 0.2%, water content about 35g / m 3 . The sulfide in the exhaust gas is mainly H 2 S and COS, the concentrations are 10ppm and 35ppm, the rest are like CS 2 The total concentration of organic sulfur is less than 1mg / m 3 ;

[0061] (1) Organic sulfur conversion: CO 2 The tail gas at the outlet of the flash tower first enters the organic sulfur conversion tower 1, and the reaction space velocity is 6000h -1 , under the condition of 60 ℃, using T504 catalyst of Hubei Institute of Chemistry, COS undergoes the following hydrolysis reaction:

[0062] COS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com