A kind of hydrophobic catalyst and preparation method thereof, preparation method of beta-ionone

A catalyst and hydrophobic technology, applied in the field of hydrophobic catalyst and its preparation, can solve the problems of inconvenient use, low concentration of sulfuric acid, high cost of sulfuric acid wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

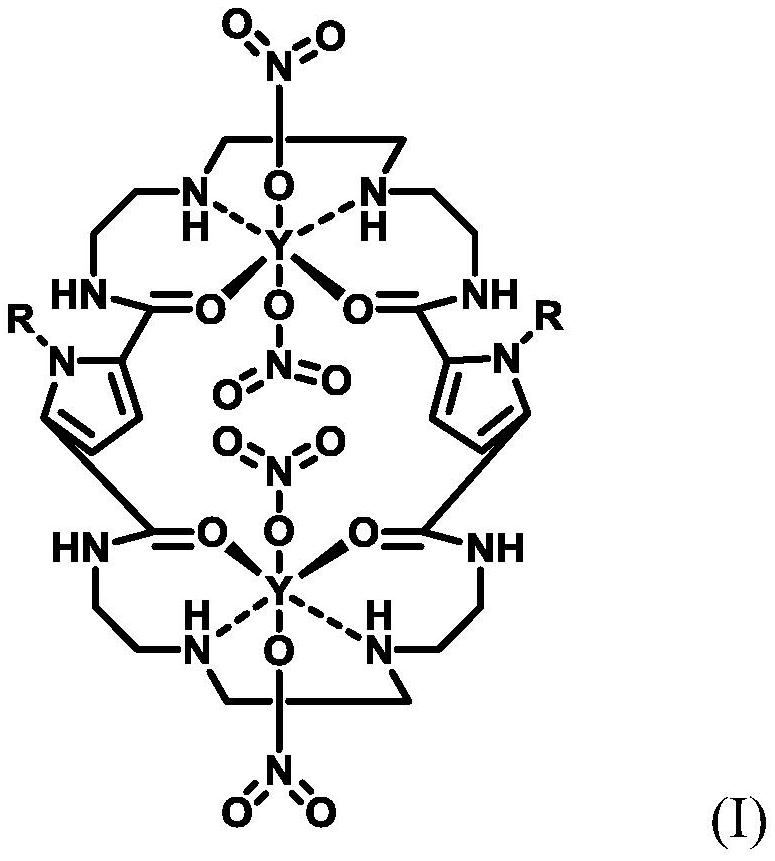

Method used

Image

Examples

Embodiment 1

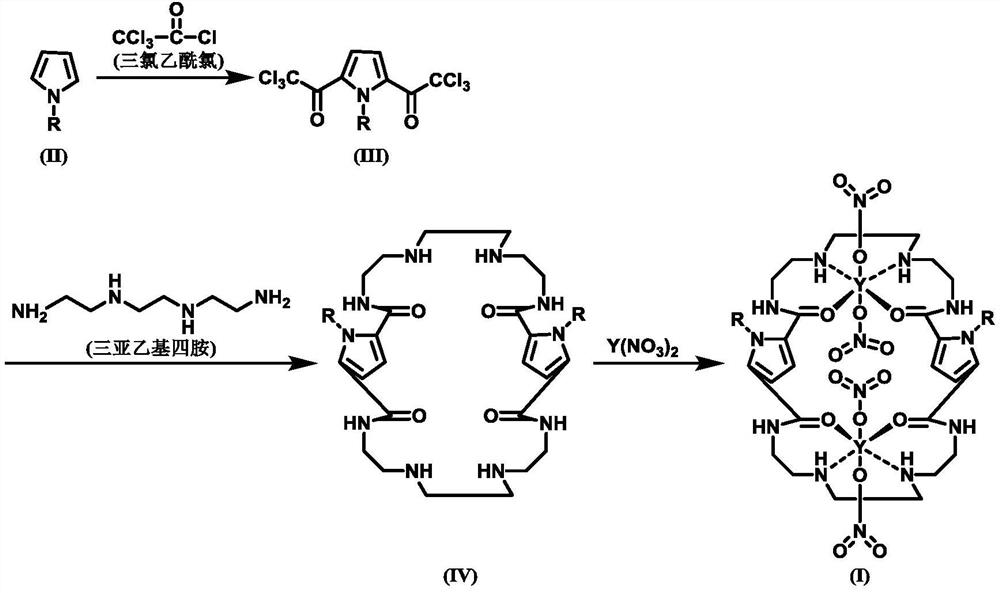

[0078] To prepare the hydrophobic catalyst H-C1, proceed as follows:

[0079] (1) Dissolve N-methylpyrrole (40.56g, 0.5mol) in ether (162.23g), mix well and prepare solution a; dissolve trichloroacetyl chloride (186.37g, 1.03mol) in ether (1677.30 In g), mix evenly to prepare solution b; under nitrogen protection and stirring, at a reaction temperature of 40°C, add solution a dropwise to solution b for 7 hours, and continue to Stir the reaction for 4h, then quench the reaction with potassium carbonate aqueous solution (5wt%, 921.40g), separate the ether phase after standing, remove the ether in vacuum, recrystallize with isopropanol, and obtain a solid after vacuum drying Its nuclear magnetic analysis data are: 1 H NMR (400MHz, CDCl 3 ,298K)δ=7.50(2H,s, Ar- H ),3.59(3H,s,N CH 3 ).

[0080] (2) Will (74.37g, 0.2mol) was dissolved in N, N-dimethylformamide (855.23g), mixed uniformly and prepared into solution c; triethylenetetramine (30.71g, 0.21mol) was dissolved in ...

Embodiment 2

[0083] To prepare the hydrophobic catalyst H-C2, proceed as follows:

[0084] (1) Dissolve N-methylpyrrole (40.56g, 0.5mol) in ether (60.84g), mix well and prepare solution a; dissolve trichloroacetyl chloride (272.73g, 1.50mol) in ether (636.37 In g), mix evenly to prepare solution b; under nitrogen protection and stirring, at a reaction temperature of 80°C, add solution a dropwise to solution b for 3 hours, and continue to Stir the reaction for 2h, then quench the reaction with potassium carbonate aqueous solution (20wt%, 138.21g), separate the ether phase after standing, remove the ether in vacuum, recrystallize with isopropanol, and obtain a solid after vacuum drying

[0085] (2) Will (74.37g, 0.2mol) was dissolved in N, N-dimethylformamide (338.79g), mixed uniformly and prepared into solution c; triethylenetetramine (35.10g, 0.24mol) was dissolved in N, N - Dimethylformamide (184.26g), mixed evenly to prepare solution d; under nitrogen protection and stirring, at a r...

Embodiment 3

[0088] Prepare hydrophobic catalyst H-C3, carry out according to the following steps:

[0089] (1) Dissolve N-ethylpyrrole (47.57g, 0.5mol) in ether (111.00g), mix well and prepare solution a; dissolve trichloroacetyl chloride (227.28g, 1.25mol) in ether (909.11 In g), mix uniformly to prepare solution b; under nitrogen protection and stirring, at a reaction temperature of 60°C, add solution a dropwise to solution b for 5 hours, and continue to Stir the reaction for 3h, then quench the reaction with potassium carbonate aqueous solution (12.5wt%, 276.42g), separate the ether phase after standing, remove the ether in vacuum, recrystallize with isopropanol, and obtain a solid after vacuum drying

[0090] (2) Will (77.17g, 0.2mol) was dissolved in N, N-dimethylformamide (516.47g), mixed uniformly and prepared into solution c; triethylenetetramine (33.05g, 0.23mol) was dissolved in N, N -Dimethylformamide (221.18g), mixed evenly to prepare solution d; under nitrogen protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com