Preparation process of iron-based powder sintered material

A technology of sintered materials and iron-based powders, which is applied in the field of preparation of iron-based powder sintered materials, can solve problems such as uneven powder mixing and affecting the quality of mixed powders, and achieve the effect of increasing the collection rate and improving the uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

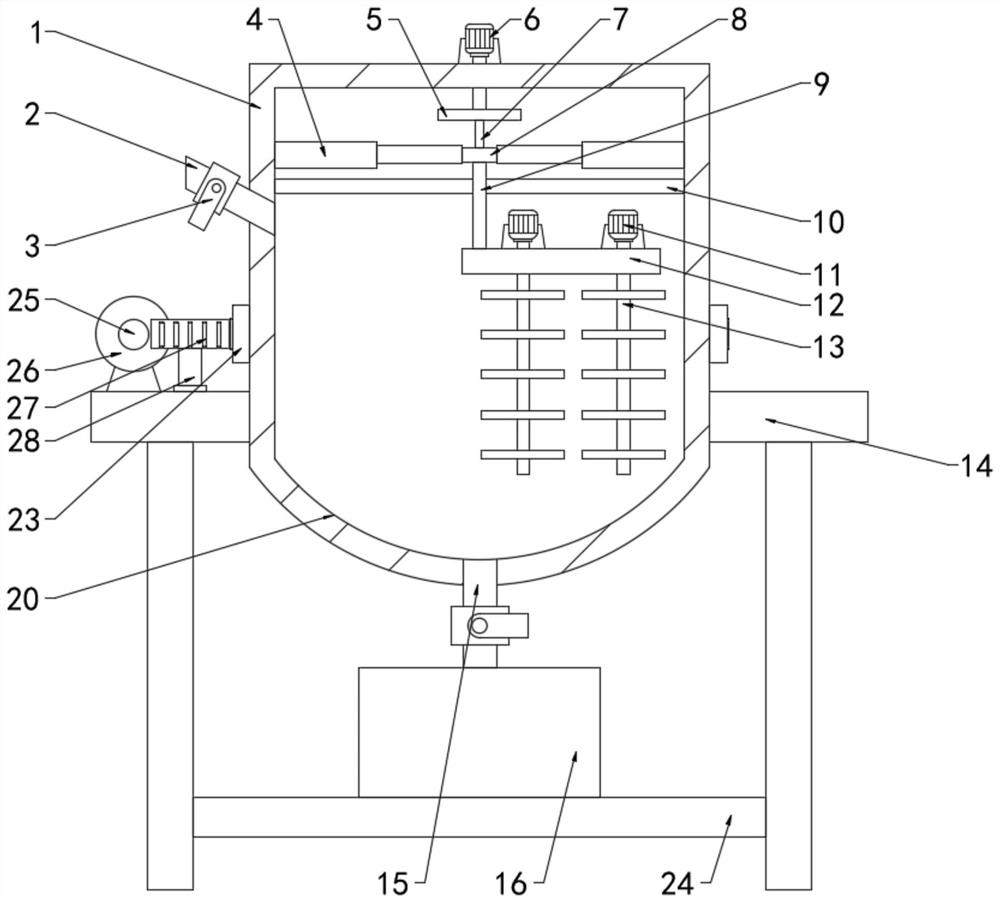

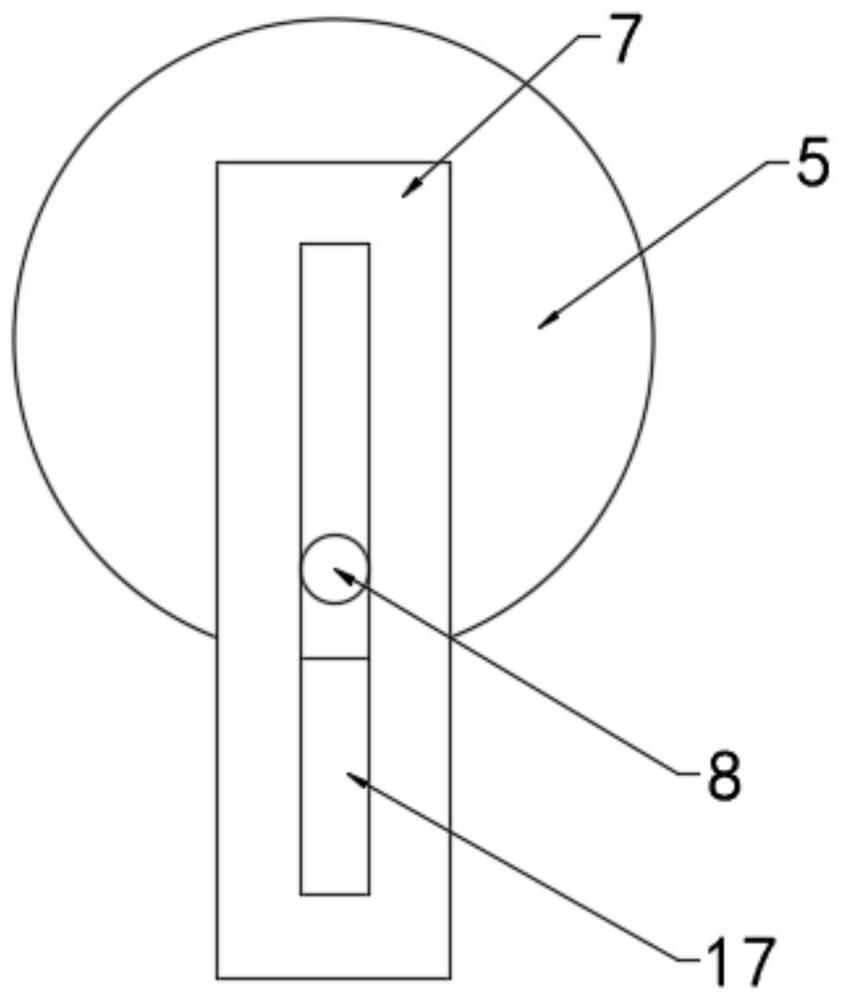

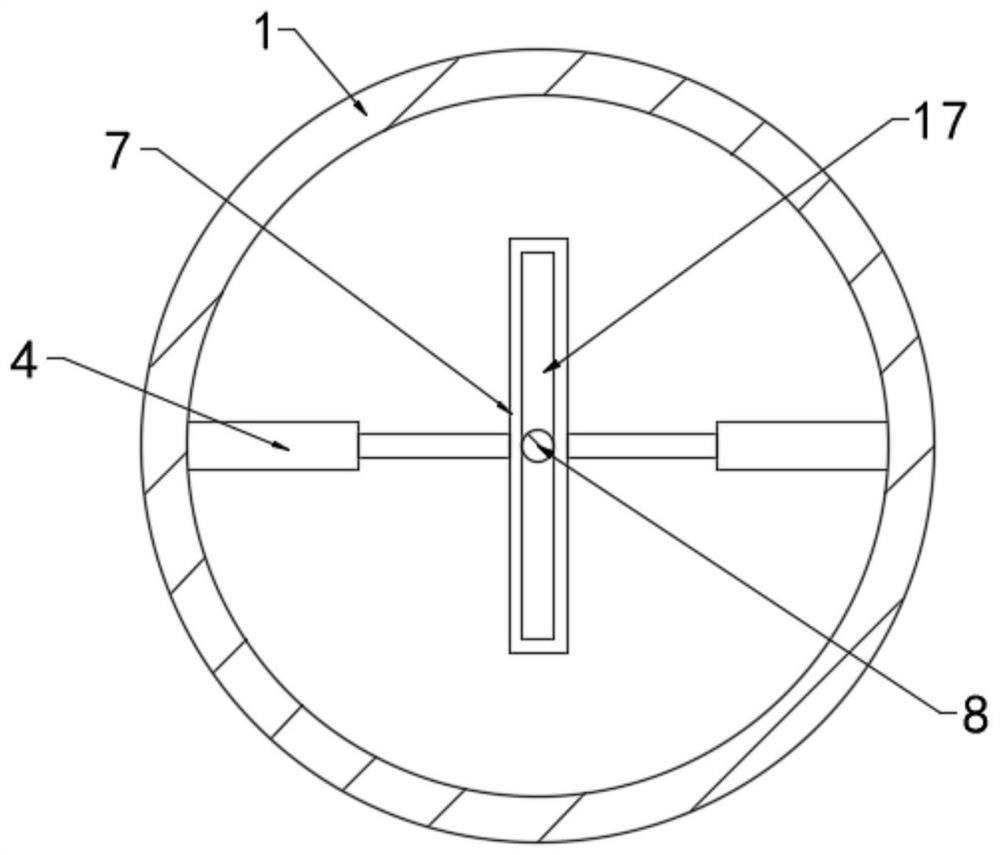

[0046] see Figure 1-6 , the present invention provides a technical solution: a preparation process of iron-based powder sintered material, including iron-based material, lubricant, alloy powder and machinability-improving powder;

[0047] The lubricant includes one or more of zinc stearate, aluminum stearate and lead stearate;

[0048] Alloy powders include one or more of sulfur powder or manganese sulfide powder;

[0049] Machinability improving powder includes one or more of graphite powder, copper powder, iron phosphide powder, molybdenum powder and nickel powder;

[0050] The preparation process of the iron-based powder sintered material includes the following steps:

[0051] S1. Obtain iron-based materials, lubricants, alloy powders, and machinability-improving powders, and mix the iron-based materials, lubricants, alloy powders, and machinability-improving powders in a mixing device to obtain mixed powders;

[0052] S2, filling the mixed powder into a mold, and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com