Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency of perovskite solar cells and restrict the commercialization process of perovskite solar cell efficiency, so as to reduce the overall cost and device performance Excellent, simple process preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

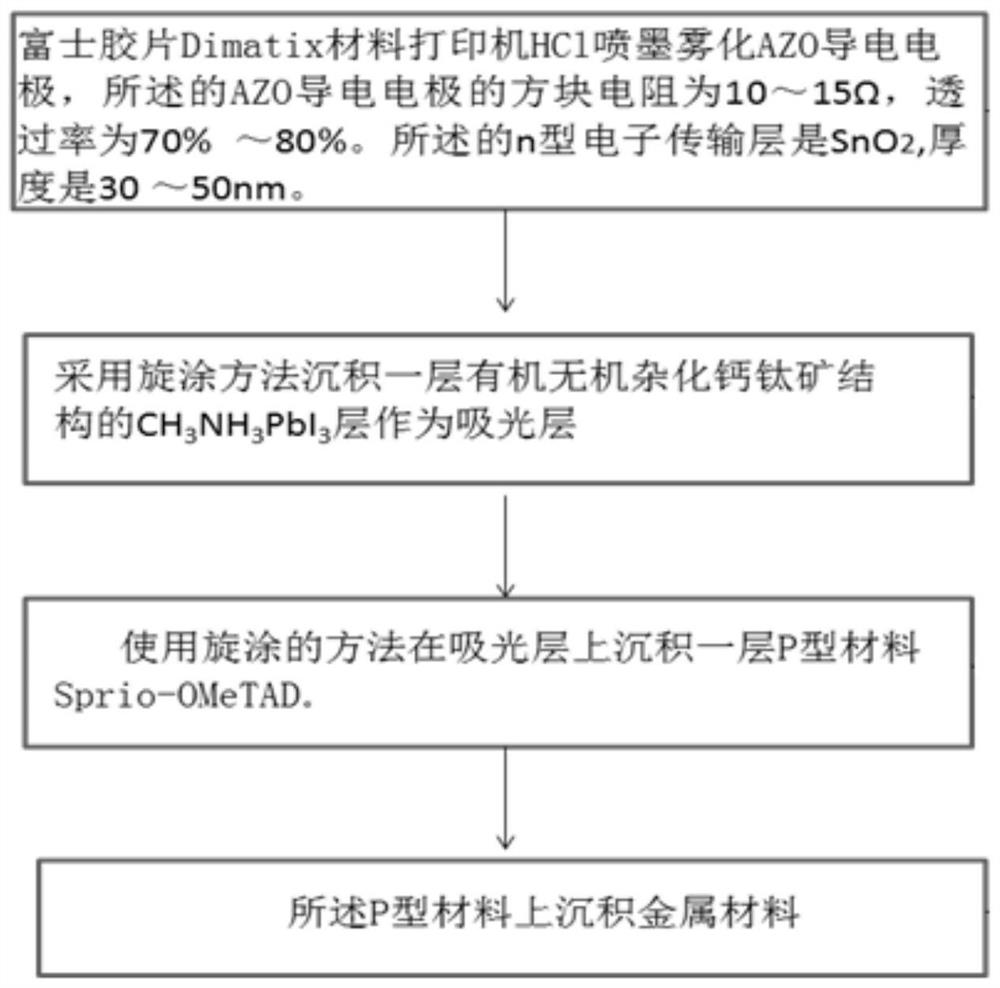

[0040] (1) AZO conductive glass surface pretreatment

[0041] The size of the AZO conductive glass is 2cm×2cm. The AZO conductive glass is ultrasonically cleaned with deionized water, acetone and alcohol in sequence, and then dried with nitrogen.

[0042] (2) HCl inkjet atomization AZO conductive electrode

[0043] Dissolve 1 mL of hydrochloric acid in 19 mL of deionized water to prepare dilute hydrochloric acid. Put the prepared dilute hydrochloric acid into the Fujifilm Dimatix material printer, ink-jet atomize the AZO conductive electrode, the atomization time is 1s, rinse with deionized water, make AZO form a layered structure, and obtain the AZO conductive electrode after atomization; SnO 2 The preparation method of the precursor liquid is: weigh tin dioxide SnO 2 Ink (SnO 2 ink) 1mL, add deionized solution to dilute to 3% volume. Put the atomized AZO conductive electrode in the spin coater to spin coat the above SnO 2 The precursor liquid is rotated at a speed of ...

Embodiment 2

[0054] (1) AZO conductive glass surface pretreatment

[0055] The size of AZO conductive glass is 2cm×2cm. The surface treatment sequence of AZO conductive glass is ultrasonic cleaning with deionized water, acetone and alcohol in turn, and then blown dry with nitrogen.

[0056] (2) HCl inkjet atomization AZO conductive electrode

[0057] Dissolve 1 mL of hydrochloric acid in 19 mL of deionized water to prepare dilute hydrochloric acid. Put the prepared dilute hydrochloric acid into the Fujifilm Dimatix material printer, ink-jet atomize the AZO conductive electrode, the atomization time is 3s, rinse with deionized water, make the AZO form a layered structure, and obtain the atomized AZO conductive electrode;

[0058] SnO 2 The method of the precursor liquid is: weigh tin dioxide SnO 2 Ink (SnO 2 ink) 2mL, add deionized solution to dilute to 3% volume. Put the atomized AZO conductive electrode in the spin coater to spin coat the above SnO 2 The precursor liquid is rotated...

Embodiment 3

[0069] (1) AZO conductive glass surface pretreatment

[0070] The size of AZO conductive glass is 2cm×2cm. The surface treatment sequence of AZO conductive glass is ultrasonic cleaning with deionized water, acetone and alcohol in turn, and then blown dry with nitrogen.

[0071] (2) HCl inkjet atomization AZO conductive electrode

[0072] Dissolve 1 mL of hydrochloric acid in 19 mL of deionized water to prepare dilute hydrochloric acid. Put the prepared dilute hydrochloric acid into the Fujifilm Dimatix material printer, ink-jet atomize the AZO conductive electrode, the atomization time is 5s, rinse with deionized water, make AZO form a layered structure, and obtain the atomized AZO conductive electrode; SnO 2 The method of the precursor liquid is: weigh tin dioxide SnO 2 Ink (SnO 2 ink) 1.5mL, add deionized solution to dilute to 3% volume. Put the atomized AZO conductive electrode in the spin coater to spin coat the above SnO 2 The precursor liquid is rotated at a speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap