Doping and dipping coating synchronously modified polycrystalline positive electrode material and solid-phase preparation method and application thereof

A cathode material and solid-phase preparation technology, applied in the field of lithium/sodium ion battery polycrystalline cathode materials and their solid-phase preparation, can solve the problems of destroying the surface structure of cathode materials, unable to prevent electrolyte corrosion, and difficult to obtain coating materials, etc. , to improve the structural stability, improve the charge-discharge efficiency and rate performance, and the energy density will not decrease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

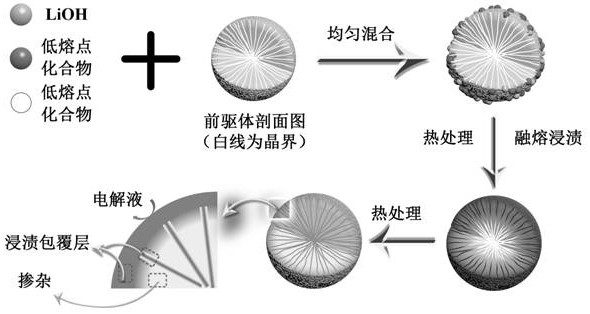

Method used

Image

Examples

Embodiment 1

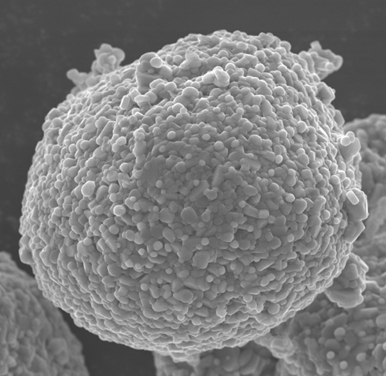

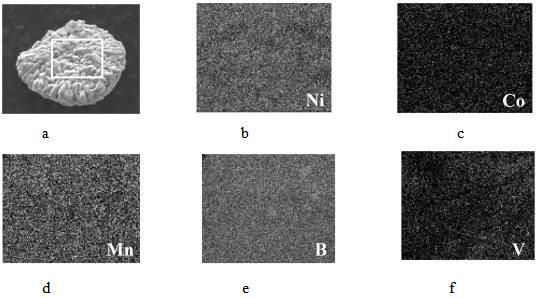

[0039] Select transition metal oxide precursors (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) with excess lithium hydroxide and the compound LiBO weighed according to molar weight 2 with V 2 o 5 (precursor and compound LiBO 2 , V 2 o 5 The molar ratio of the mixture is 1:0.5%:2%, and the mixture is placed in a tube furnace. Under an oxygen atmosphere, the temperature is raised to the first-stage sintering temperature of 690°C at a rate of 5°C / min (V 2 o 5 melting point) and keep it warm for 3 hours, then raise the temperature to the second-stage sintering temperature of 750°C and keep it warm for 12 hours, then naturally cool to room temperature, crush and grind, and obtain a lithium-ion battery positive electrode material that is simultaneously modified by doping and impregnation coating.

[0040] The B element doping amount of the positive electrode material is 0.5%, the thickness of the coating layer on the surface of the primary particle is 1 nm, and the thickness of the coating...

Embodiment 2

[0051] Select transition metal oxide precursors (Ni 0.6 co 0.2 mn 0.2 (OH) 2 ) with excess lithium hydroxide and the compound BeF weighed according to the molar weight 2 with MnO 2 (precursor and compound BeF 2 , MnO 2 The molar ratio is 1:1.5%:2%) and mixed evenly, the mixture is placed in a tube furnace, and in an oxygen atmosphere, the temperature is raised to the first stage sintering temperature of 555°C at a rate of 5°C / min (BeF 2 melting point) and keep it warm for 5 hours, then raise the temperature to the second-stage sintering temperature of 850°C and keep it warm for 18 hours, then naturally cool to room temperature, crush and grind, and obtain a lithium-ion battery positive electrode material that is simultaneously modified by doping and impregnation coating.

[0052] The doping amount of Be and F elements in the positive electrode material is 1.5% and 3%, the thickness of the coating layer on the surface of the primary particle is 0.8nm, and the thickness of...

Embodiment 3

[0056] Select transition metal oxide precursors (Ni 0.7 co 0.1 mn 0.2 (OH) 2 ) with excess lithium hydroxide and the compound Sb taken according to the molar weight 2 o 3 with LiBF 4 (precursor and compound Sb 2 o 3 、LiBF 4 The molar ratio is 1:8%:0.5%) and mixed evenly, the mixture is placed in a tube furnace, and in an oxygen atmosphere, the temperature is raised to the first stage sintering temperature of 655°C at a rate of 5°C / min (Sb 2 o 3 melting point) and keep it warm for 6 hours, then raise the temperature to the second-stage sintering temperature of 800°C and keep it warm for 15 hours, then naturally cool to room temperature, crush and grind, and obtain a lithium-ion battery positive electrode material that is simultaneously modified by doping and impregnation coating.

[0057] The doping amount of B and F elements in the positive electrode material is 0.5% and 2%, the thickness of the coating layer on the surface of the primary particle is 3nm, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com