Amoxicillin capsule and preparation method thereof

An amoxicillin capsule and amoxicillin technology, applied in the field of capsule preparation, can solve the problems of large relative particle size of amoxicillin heavy powder, poor stability of amoxicillin capsules, poor dissolution rate of amoxicillin capsules, etc. The effect of amoxicillin light powder flying, shortening mixing time and improving drug dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of preparation method of amoxicillin capsule

[0032] The present embodiment is a preparation method of amoxicillin capsules, and the specific preparation process includes the following steps carried out in sequence:

[0033] 1) Set the equipment parameters of the dry granulator: the stirring speed is 17rpm, the screw feeding speed is 56rpm, the pressing roller pressure is 6.8MPa, the pressing roller rotating speed is 13rpm, the pressing roller temperature is 25°C, the granulation rotating speed is 130rpm, The pore size of the particle screen is 0.84mm, and the mesh size of the rotary vibrating screen is 20 mesh, 30 mesh and 80 mesh

[0034] At a temperature of 25°C and a humidity of 52%, take the amoxicillin raw material drug and dry it with nitrogen at 25°C for 30 seconds, then add it to the hopper of a dry granulator for granulation, and collect it through a 20-mesh sieve and fail to pass through a 20-mesh sieve. Amoxicillin heavy powder (particl...

Embodiment 2~6

[0040] The preparation method of embodiment 2~6 amoxicillin capsule

[0041] Embodiments 2 to 6 are respectively a preparation method of amoxicillin capsules, and their steps are basically the same as those in Embodiment 1, the difference is only in the amount of raw materials and process parameters, see Table 1 for details:

[0042] List of each process parameter in table 1 embodiment 2~6

[0043]

[0044]

[0045] The content of the other parts of Examples 2-6 is the same as that of Example 1.

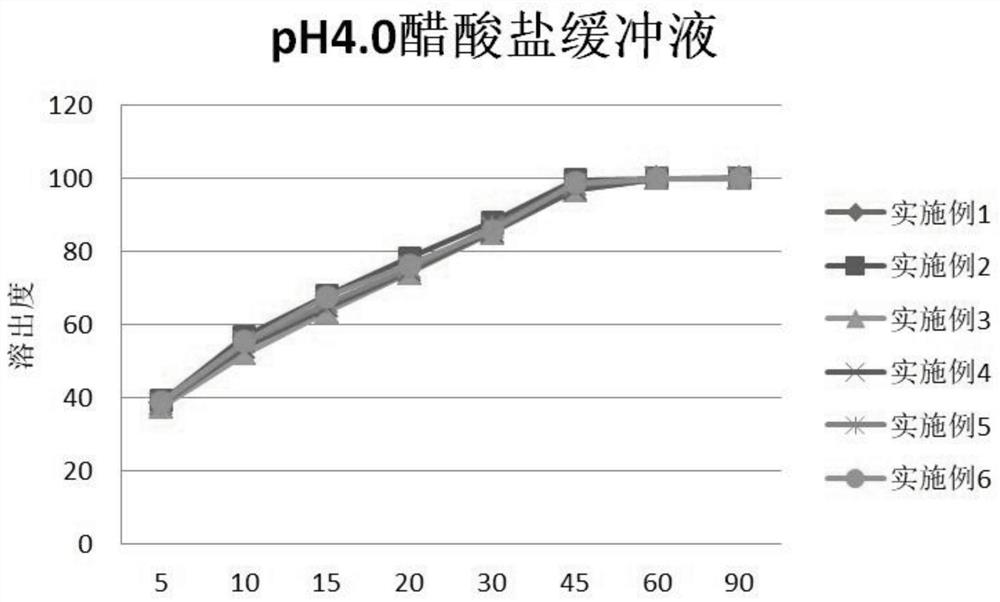

[0046] The amoxicillin capsules prepared in Examples 1-6 have good stability and high dissolution rate.

experiment example 1

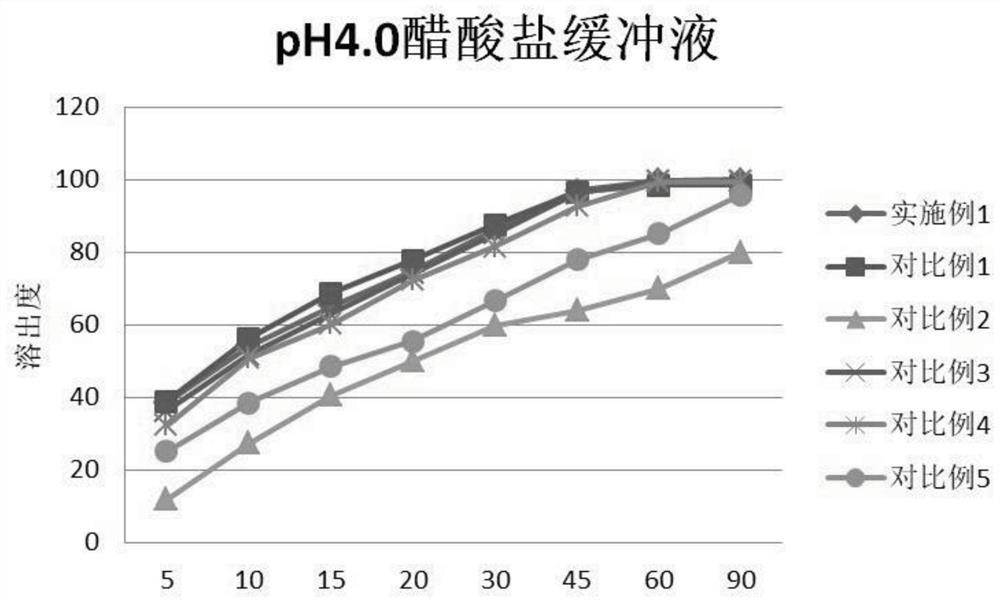

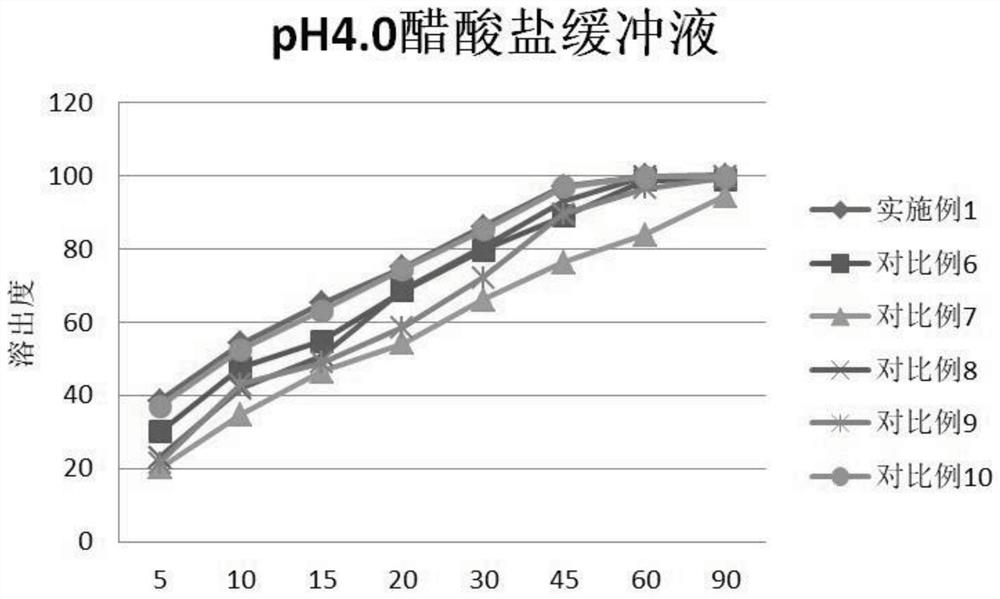

[0047] The dissolution rate determination of experimental example 1 amoxicillin capsule

[0048] Comparative examples 1-10 are the comparative tests of the preparation process of amoxicillin capsules in embodiment 1, the difference is only in:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com