Large-flow-state cement-based grouting material for semi-flexible pavement and preparation method of large-flow-state cement-based grouting material

A technology of semi-flexible pavement and grouting material, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Combine good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A large fluid cement-based grouting material for semi-flexible pavement, the parts by weight of each component are: 50 parts of rapid hardening sulfoaluminate cement, 25 parts of modified microbeads, 20 parts of fine aggregate, 0.02 parts of early strength agent 0.3 parts of water reducer, 0.08 parts of water retaining agent, 0.1 part of defoamer, 4.5 parts of expansion agent and 30 parts of water.

[0032] The rapid-hardening sulfoaluminate cement is rapid-hardening early-strength sulfoaluminate cement of 42.5 strength grade.

[0033] The fine aggregate is ultrafine quartz sand with a particle size of 100-200 mesh, SiO 2 Content ≥ 96 wt.%.

[0034] Described accelerator is lithium carbonate.

[0035] The water reducer is a powder water reducing polycarboxylate water reducer.

[0036] The water retaining agent is 400 viscosity cellulose ether.

[0037] The defoamer is a polyether modified polysiloxane defoamer.

[0038] The expansion agent is calcium sulfoaluminate...

Embodiment 2

[0046] According to the method of Example 1, the semi-flexible pavement is prepared with a large flow state cement-based grouting material. The difference is that the preparation method of the modified microbeads is: get 85 parts of fly ash microbeads, 5 parts of 2000 molecular weight polyethylene Glycol and 10 parts of sodium lauryl sulfate are fully mixed with a high-speed mixer for 15 minutes at a speed of 2000 r / min. Among them, the particle size of fly ash microbeads is 0.1-5.0 μm.

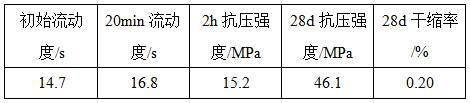

[0047] According to JTT / 1238-2019 "Cement-based grouting materials for semi-flexible mixtures", the large-flow cement-based grouting materials for semi-flexible pavements prepared in this example were tested, and the results are as follows:

[0048]

[0049] According to the technical indicators of JTG F40-2004 "Technical Specifications for Highway Asphalt Pavement Construction" of the Ministry of Transport, the semi-flexible pavement of this embodiment is poured into the large-void asphal...

Embodiment 3

[0052] According to the method of Example 1, the large-flow cement-based grouting material for semi-flexible pavement is prepared. The difference is that the preparation method of the modified microbeads is: get 90 parts of fly ash microbeads, 3 parts of 1500 molecular weight polyethylene Glycol and 7 parts of sodium dodecyl sulfonate are fully mixed with a high-speed mixer for 15 minutes at a speed of 2500 r / min to obtain the product. Among them, the particle size of fly ash microbeads is 0.1-5.0 μm.

[0053] According to JTT / 1238-2019 "Cement-based grouting materials for semi-flexible mixtures", the large-flow cement-based grouting materials for semi-flexible pavements prepared in this example were tested, and the results are as follows:

[0054]

[0055] According to the technical indicators of JTG F40-2004 "Technical Specifications for Highway Asphalt Pavement Construction" of the Ministry of Transport, the semi-flexible pavement of this embodiment is poured into the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com