PA6/ASA alloy material and preparation method thereof

A technology of alloy material and ASA resin, which is applied in the field of PA6/ASA alloy material and its preparation, can solve the problems of poor mechanical properties, large difference in polarity and crystallinity, and poor appearance of PA6/ASA alloy, and achieve high toughness , The preparation method is simple, and the effect of appearance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

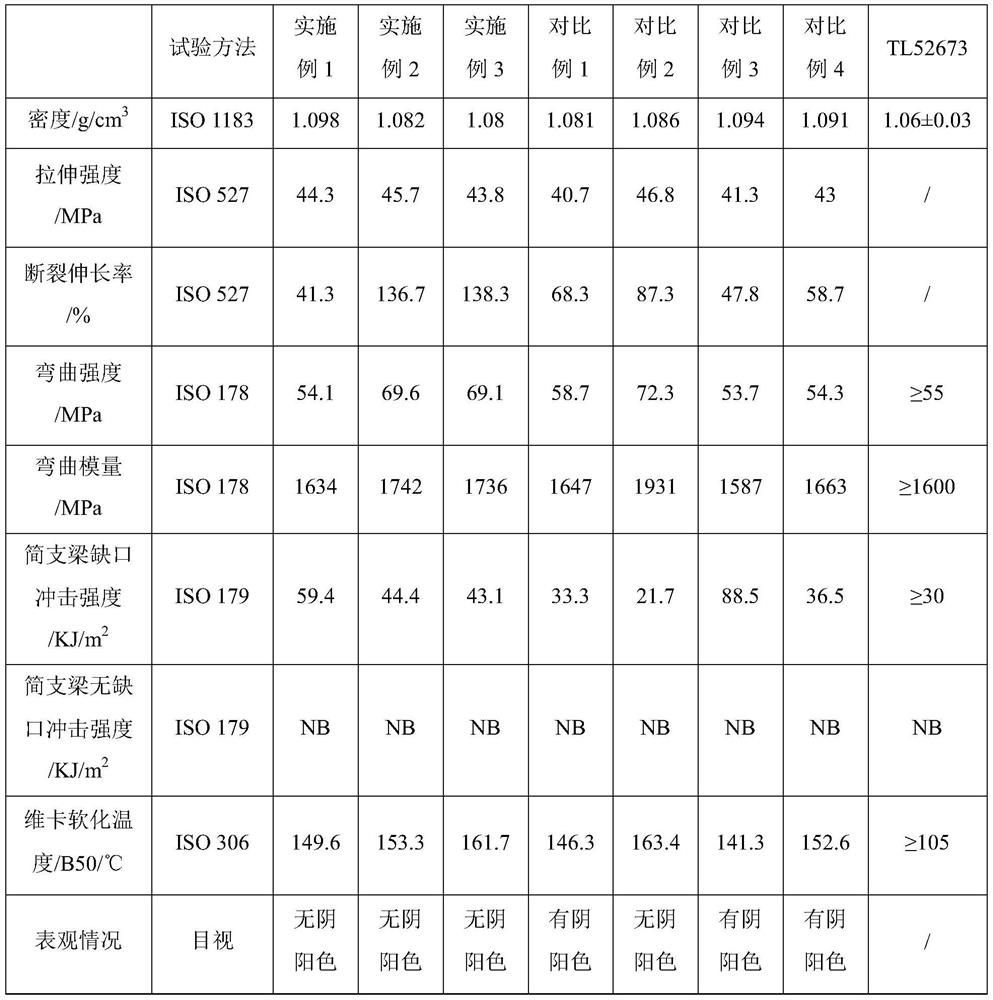

Examples

Embodiment 1

[0030] The preparation method of PA6 / ASA alloy material in the present embodiment is:

[0031] 60 parts of PA6 resin, 30 parts of ASA resin (prepared by emulsion polymerization), 5 parts of AS resin, 5 parts of SMA, 0.3 part of N,N'-bis-(3-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionyl) hexamethylenediamine, 0.5 parts of pentaerythritol stearate are thoroughly mixed, then added into a twin-screw extruder, melted and extruded to obtain a PA6 / ASA alloy material, wherein the twin-screw extruder The processing parameters of the machine are: 200°C in zone 1, 230°C in zone 2, 240°C in zone 3 and 4, 230°C in zone 5 to zone 7, 220°C in zone 8 and 9, temperature of the head at 240°C, screw speed Controlled at 450rpm.

Embodiment 2

[0033] The preparation method of PA6 / ASA alloy material in the present embodiment is:

[0034] 45 parts of PA6 resin, 25 parts of ASA resin (prepared by emulsion polymerization), 5 parts of ABS resin with a glue content of 50%-60%, 15 parts of AS resin, 10 parts of SMA, 0.2 parts of N,N'-bis-( 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, 0.3 parts of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxy Phenyl)propionyl)hexamethylenediamine, 0.2 parts of silicone lubricant, 0.3 parts of N-N-hexylenebisstearamide, mixed well, then added to a twin-screw extruder, melted and extruded to obtain PA6 / ASA alloy material, in which the processing parameters of the twin-screw extruder are: 220°C in zone 1, 245°C in zone 2, 260°C in zone 3 and 4, 250°C in zone 5 to zone 7, 240°C in zone 8 and 9 , the head temperature is 250°C, and the screw speed is controlled at 440rpm.

Embodiment 3

[0036] The preparation method of PA6 / ASA alloy material in the present embodiment is:

[0037] 48 parts of PA6 resin, 20 parts of ASA resin (prepared by emulsion polymerization), 5 parts of ABS resin with a glue content of 50%-60%, 5 parts of maleic anhydride grafted SEBS, 20 parts of AS resin, 3 parts of SMA, 2 parts Parts of MBS, 0.2 parts of tris(2,4-di-tert-butyl)phenyl phosphite, 0.3 parts of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Acyl)hexamethylene diamine, 0.3 parts of silicone lubricant, 0.3 parts of pentaerythritol stearate are fully mixed, then added to a twin-screw extruder, melted and extruded to obtain a PA6 / ASA alloy material, wherein, double The processing parameters of the screw extruder are: Zone 1 210°C, Zone 2 250°C, Zone 3 and Zone 4 260°C, Zone 5 to Zone 7 245°C, Zone 8 and Zone 9 230°C, Head Temperature 250°C, The screw speed is controlled at 500rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com