Composite microcapsule type fat substitute and preparation method thereof

A fat substitute and microcapsule technology, which is applied in the field of food processing, can solve the problems of poor taste, high proportion or complete replacement of fat, and achieve the effect of maintaining texture characteristics and flavor, improving simulation effect, and improving water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

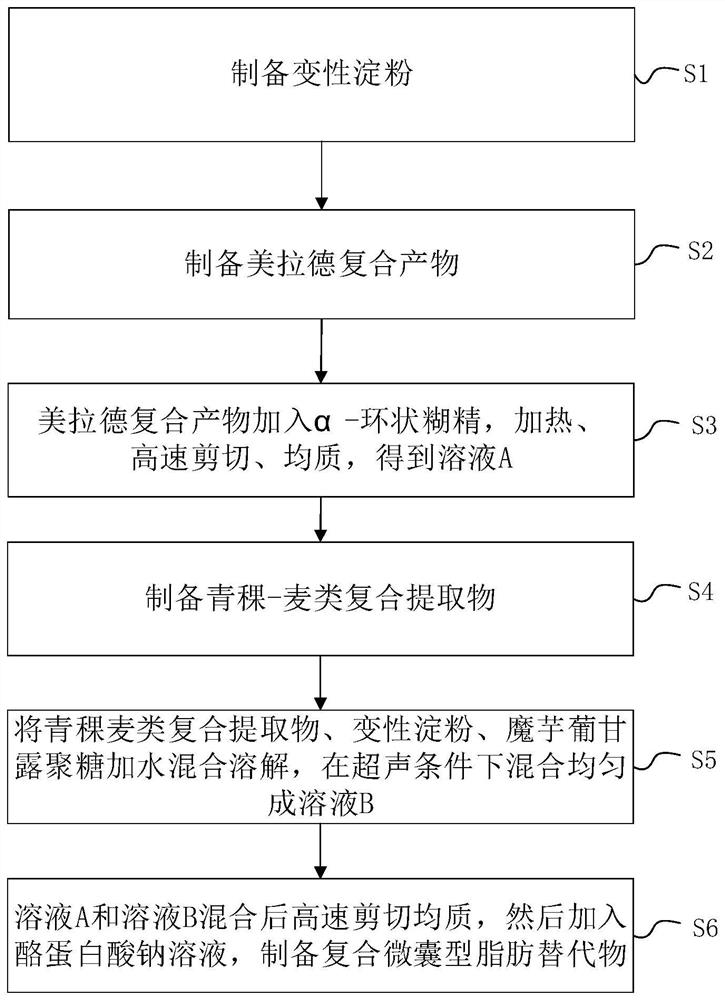

[0035] Based on the composition of the above formula, the present invention provides a method for preparing a compound microcapsule fat substitute, such as figure 1 shown, including:

[0036] Step S1, preparing modified starch.

[0037] S11. Put the raw starch into a ball mill for ultrafine grinding, and the final mesh size is 600-1200 mesh.

[0038] In this step, the raw material starch is one or more of corn starch, waxy corn starch, tapioca starch, potato starch and bean starch.

[0039] S12. Mix the raw material starch with water in a reaction kettle to prepare starch milk. The mass concentration of starch milk is 25%-50%.

[0040] S13. Add sodium chloride and mix evenly, adjust the pH value to 8-12 with alkali, add sodium trimetaphosphate, adjust the microwave generator, and let the materials in the reactor react under microwave conditions for a period of time.

[0041] The amount of sodium chloride added accounts for 3%-8% of the starch mass, sodium hydroxide is used...

Embodiment 1

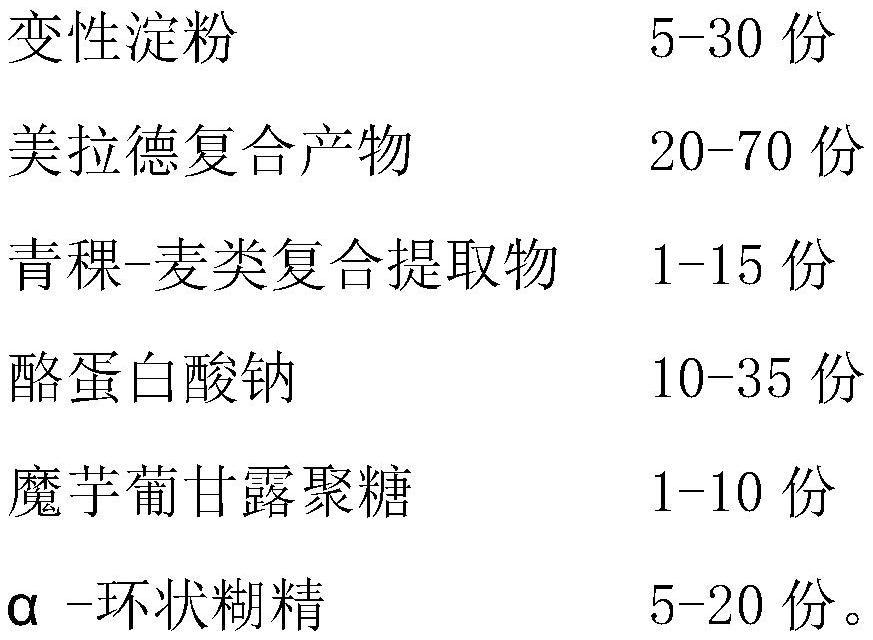

[0065] Composite microcapsule fat substitute is composed as follows (by mass parts):

[0066] 15 parts modified starch (the raw material starch is corn starch)

[0067] 30 parts of Maillard composite products (containing 10% soybean protein isolate, 12% whey protein, 4% isomaltose oligosaccharide, and 2% glucose in protein aqueous solution, both are mass percentages)

[0068] 10 parts of highland barley-wheat compound extract (the mass ratio of highland barley, rye and wheat is 6:1:1)

[0069] Sodium caseinate 20 parts

[0070] Konjac Glucomannan 2 parts

[0071] 10 parts of α-cyclodextrin

Embodiment 2

[0073] The composition of the compound microcapsule fat substitute is as follows:

[0074] 12 parts modified starch (the raw material starch is waxy corn starch)

[0075] 35 parts of Maillard complex products (12% of egg white protein, 10% of whey protein, 5% of isomaltose oligosaccharide, and 3% of glucose in the protein water solution, both in mass percentage)

[0076] Highland barley-wheat compound extract 8 parts (mass ratio of highland barley and rye is 2:1)

[0077] Sodium caseinate 18 parts

[0078] Konjac Glucomannan 4 parts

[0079] 12 parts of α-cyclodextrin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com