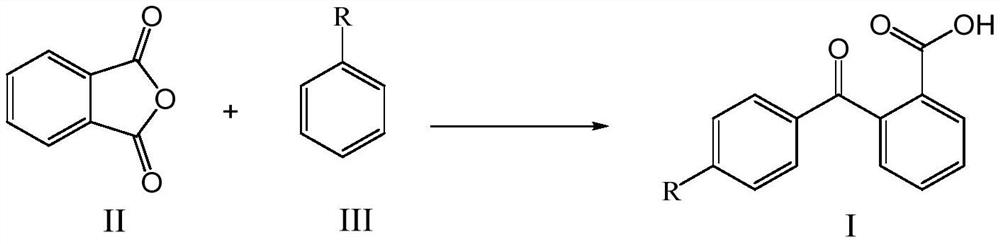

Method for synthesizing pitavastatin calcium intermediate by microchannel reactor

A microchannel reactor, pitavastatin calcium technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., can solve the problem of large reaction volume, severe heat release, There are many problems such as impurities, so as to achieve the effect of mild reaction conditions, simple post-treatment and strong heat transfer ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

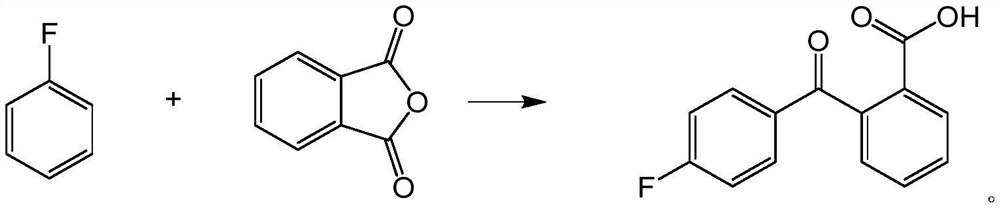

[0035] (1) Hypothylation of fluorobenzene, sodium carbonate and dichloromethane, resulting in a homogeneous a solution, a concentration of fluorobenzene in a homogeneous a solution of 1.0 mol / L, sodium carbonate and fluorobenzene 1.5: 1.

[0036] (2) Mixed phthalic anhydride was mixed with dichloromethane to obtain a homogeneous B solution, and the concentration of phthalic anhydride in a homogeneous B solution was 1.5 mol / L.

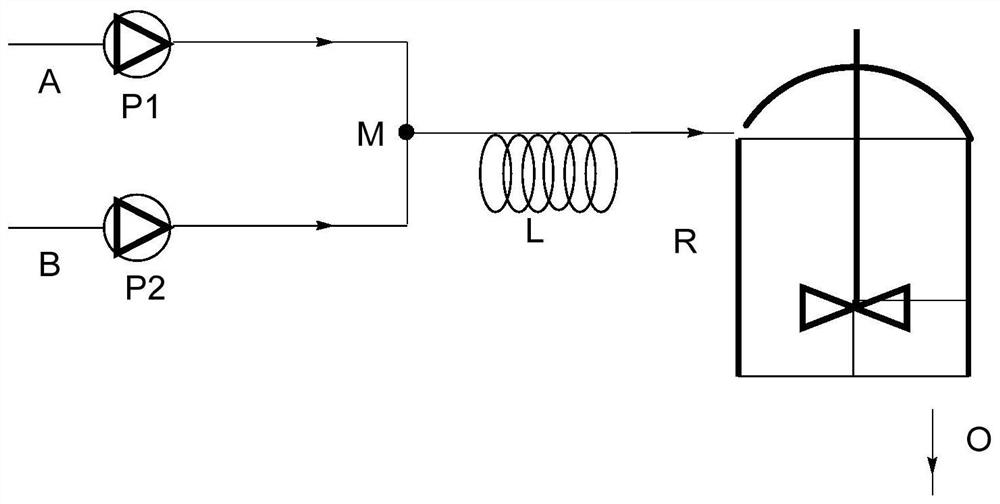

[0037] (3) The microreactive mixer M and the reaction module L are placed at a predetermined temperature, and the homozygous A solution obtained in step (1) and the homozygs (2) obtained in the step (2) are respectively The pump P1, the second flow pump P2 is pumped into the microreactive mixer M by a flow rate ratio (2: 1), and the first flat stream pip pumps the homogeneous A solution into the microsparic mixer M, and the flow rate is 0.5mL / MIN, mixed uniformly transferred to the reaction module L (inner diameter: 0.1 mm, length: 15 m) for the Fu-gr...

Embodiment 2

[0040] (1) Benzene, lithium carbonate and dichloroethane are mixed uniform to obtain a homogeneous a solution, and the concentration of fluorobenzene in the homogeneous A solution is 2.0 mol / L, the molar ratio of lithium carbonate and fluorobenzene is 2.0: 1. .

[0041] (2) Mixed phthalic anhydride was mixed with dichloroethane to obtain a homogeneous B solution, and the concentration of phthalic anhydride in a homogeneous B solution was 2.5 mol / L.

[0042] (3) The microreactive mixer M and the reaction module L are placed at a predetermined temperature, and the homozygous A solution obtained in step (1) and the homozygs (2) obtained in the step (2) are respectively The pump P1, the second flow pump P2 is pumped into the microspactic mixer M by a flow rate ratio (4: 1), and the first state flow pump P1 pumps the above-mentioned a solution into the microspactic mixer M, which is 10 ml / min. After mixing is uniform, transferred to the reaction module L (inner diameter: 5 mm, le...

Embodiment 3

[0045] (1) Benzene, potassium carbonate and methyl tert-butyl ether are mixed to obtain a homogeneous a solution, and the concentration of fluorobenzene in the homogeneous A solution is 0.1 mol / L, the molar ratio of potassium carbonate and fluorobenzene is 0.5. :1.

[0046] (2) The phthalic anhydride was mixed with methyl tert-butyl ether to obtain a homogeneous B solution, and the concentration of phthalic anhydride in a homogeneous B solution was 0.1 mol / L.

[0047] (3) The microreactive mixer M and the reaction module L are placed at a predetermined temperature, and the homozygous A solution obtained in step (1) and the homozygs (2) obtained in the step (2) are respectively The pump P1, the second flow pump P2 is pumped into the microspactic mixer M by a flow rate ratio (3: 1), and the first state of which pumps the homogeneous A solution into the microspactic mixer M, which is 15 ml / min. After mixing is uniform, transferred to the reaction module L (inner diameter: 10 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com