Ultrasonic coupling agent and preparation method and application thereof

An ultrasonic coupling agent and lubricant technology, applied in the field of ultrasonic coupling agent and its preparation, can solve the problems of polluting the workpiece surface, poor adhesion effect, and affecting detection results, etc., achieve high signal-to-noise ratio, improve flaw detection depth, Good sound permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

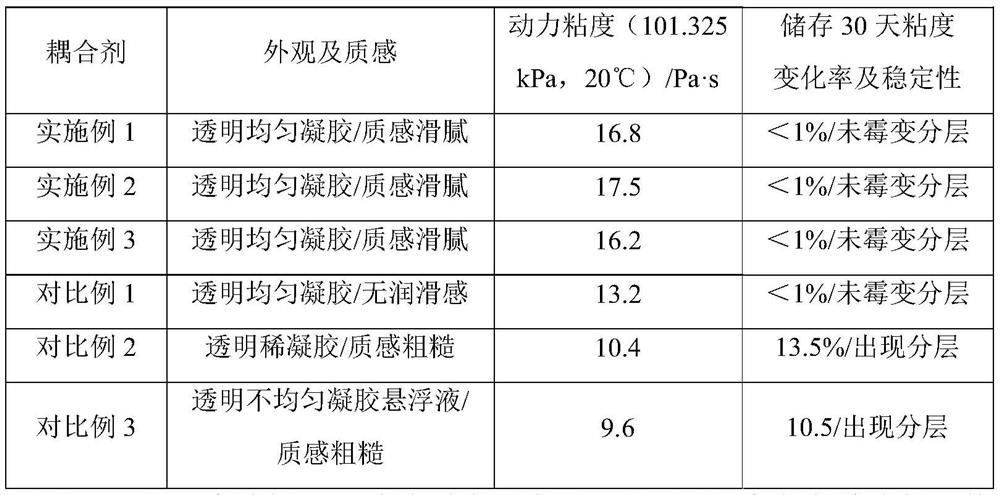

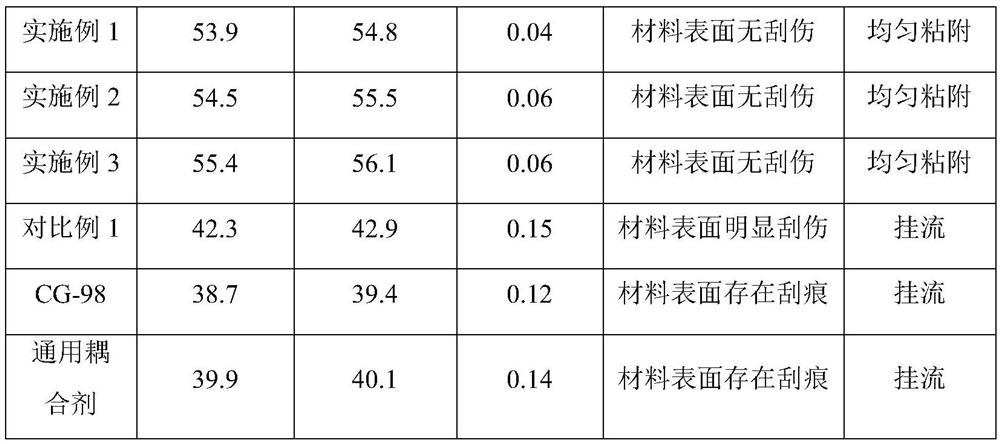

[0052] The technical solutions of the present invention will be further described below in conjunction with specific examples.

[0053] The present invention provides an ultrasonic coupling agent, the mass parts of its preparation raw materials are shown in Table 1 below, and the preparation method includes the following steps:

[0054] (1) Add phthalic anhydride and glyceryl monostearate into a round-bottomed flask with a reflux device at a mass ratio of 1:2.2, and reflux for 2 hours under nitrogen protection at about 125°C to obtain phthalic acid Glyceryl monostearate (PAGM);

[0055] (2) Take 12 parts by mass of PAGM prepared in step (1), dissolve it in 12 parts by mass of ethanol, add 1 part by mass of sodium hydroxide and 100 parts by mass of deionized water, fully mix, and place the mixture at about 60 ° C Stir for about 2.5 hours under the same conditions to obtain a liquid lubricant.

[0056] (3) After wetting the carbomer with a small amount of ethanol, add it to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com