Modified graphene anti-corrosion coating as well as preparation method and application thereof

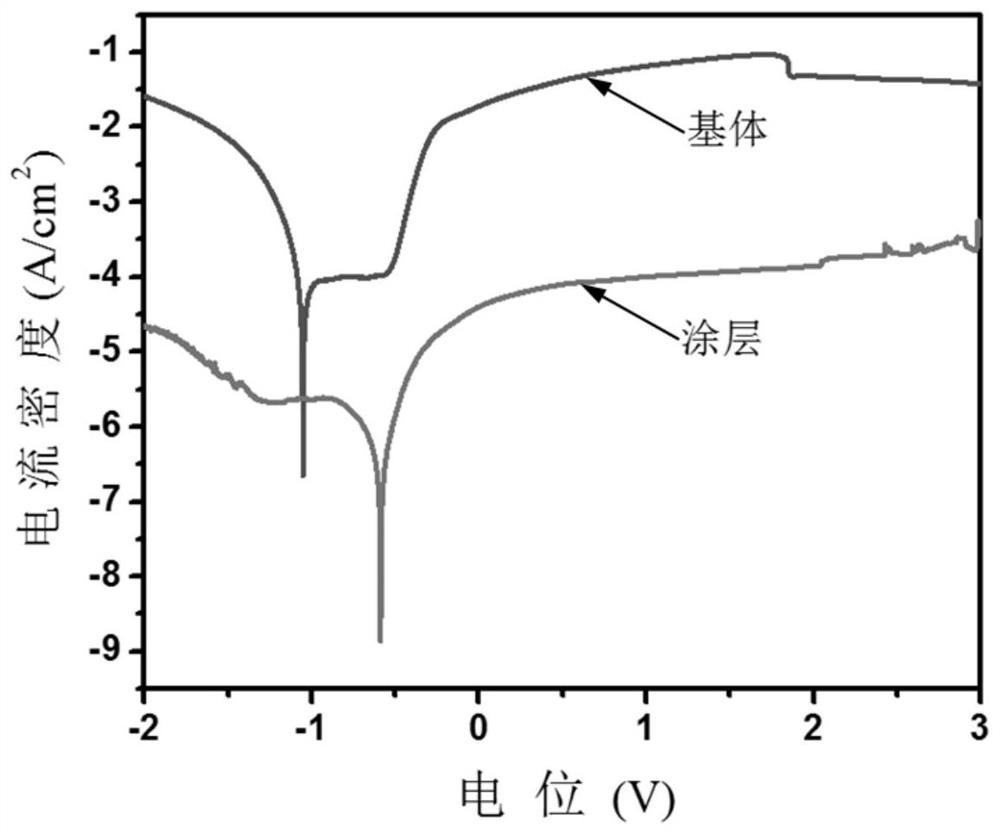

An anti-corrosion coating and graphene technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of difficult peeling and uneven distribution of epoxy resin, and achieve the effects of good acid-base stability, extended service life, and good UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for modified graphene anticorrosion coating, comprising the steps:

[0040] (1) Preparation of paint paste:

[0041] After dissolving the acrylic resin in xylene, adding an anti-precipitation agent therein, dispersing until uniform, and then filtering to obtain solution A;

[0042] Dissolving tannic acid in ethanol, dispersing until uniform and filtering to obtain solution B;

[0043] Mix solution A and solution B under magnetic stirring for 3 hours to obtain a millbase;

[0044] Wherein, the mass ratio of acrylic resin and tannic acid is 80:1;

[0045] (2) Preparation of graphene oxide@ZrO 2 Material:

[0046] S1, uniformly mixing nano zirconia and graphene oxide to obtain a mixed powder;

[0047] Wherein, the mass of the nano-zirconia accounts for 50wt% of the total amount of the mixed powder;

[0048] S2. Sintering of the mixed powder: the mixed powder in step S1 is sintered by discharge plasma, the heating rate is 70°C / min, the sintering tem...

Embodiment 2

[0056] A preparation method for modified graphene anticorrosion coating, comprising the steps:

[0057] (1) Preparation of paint paste:

[0058] After dissolving the acrylic resin in xylene, adding an anti-precipitation agent therein, dispersing until uniform, and then filtering to obtain solution A;

[0059] Dissolving tannic acid in isopropanol, dispersing until uniform, and filtering to obtain solution B;

[0060] Mix solution A and solution B under magnetic stirring for 2.5 hours to obtain a paint slurry;

[0061] Wherein, the mass ratio of acrylic resin and tannic acid is 90:1;

[0062] (2) Preparation of graphene oxide@ZrO 2 Material:

[0063] S1, uniformly mixing nano zirconia and graphene oxide to obtain a mixed powder;

[0064] Wherein, the mass of the nano-zirconia accounts for 40wt% of the total amount of the mixed powder;

[0065] S2. Sintering of the mixed powder: the mixed powder in step S1 is sintered by discharge plasma, the heating rate is 90°C / min, the ...

Embodiment 3

[0073] A preparation method for modified graphene anticorrosion coating, comprising the steps:

[0074] (1) Preparation of paint paste:

[0075] After dissolving the acrylic resin in xylene, adding an anti-precipitation agent therein, dispersing until uniform, and then filtering to obtain solution A;

[0076] Dissolving tannic acid in n-amyl alcohol, dispersing until uniform, and then filtering to obtain solution B;

[0077] Mix solution A and solution B for 2 hours under magnetic stirring to obtain a millbase;

[0078] Wherein, the mass ratio of acrylic resin and tannic acid is 100:1;

[0079] (2) Preparation of graphene oxide@ZrO 2 Material:

[0080] S1, uniformly mixing nano zirconia and graphene oxide to obtain a mixed powder;

[0081] Wherein, the mass of the nano-zirconia accounts for 30wt% of the total amount of the mixed powder;

[0082] S2. Sintering of the mixed powder: the mixed powder in step S1 is sintered by discharge plasma, the heating rate is 110°C / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com