High-stability magnetic immobilized laccase, preparation method thereof and method for efficiently degrading dye

An immobilized laccase, high stability technology, applied in biochemical equipment and methods, immobilized on or in inorganic carriers, chemical instruments and methods, etc. Improved dispersion, improved metal ion tolerance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A preparation method for highly stable magnetically immobilized laccase, comprising the following steps:

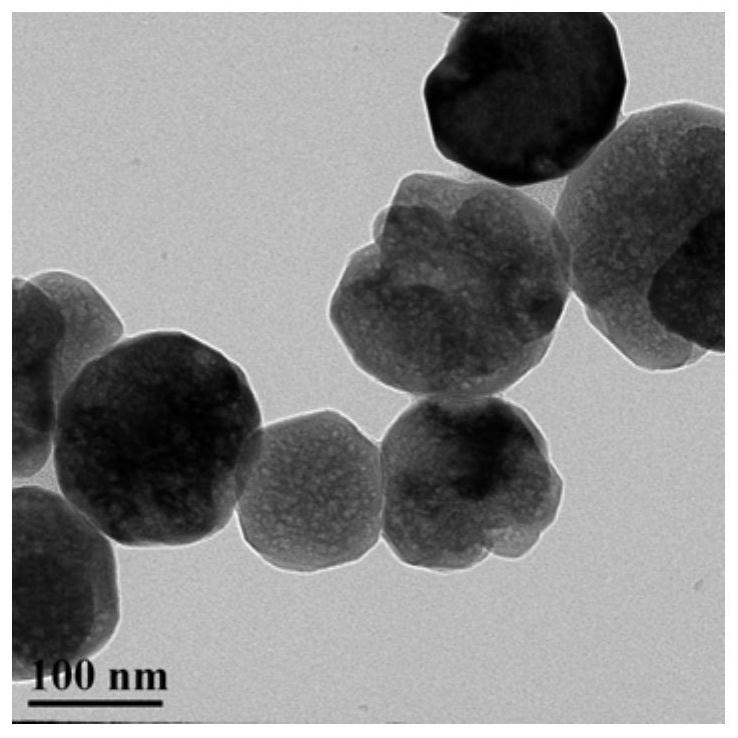

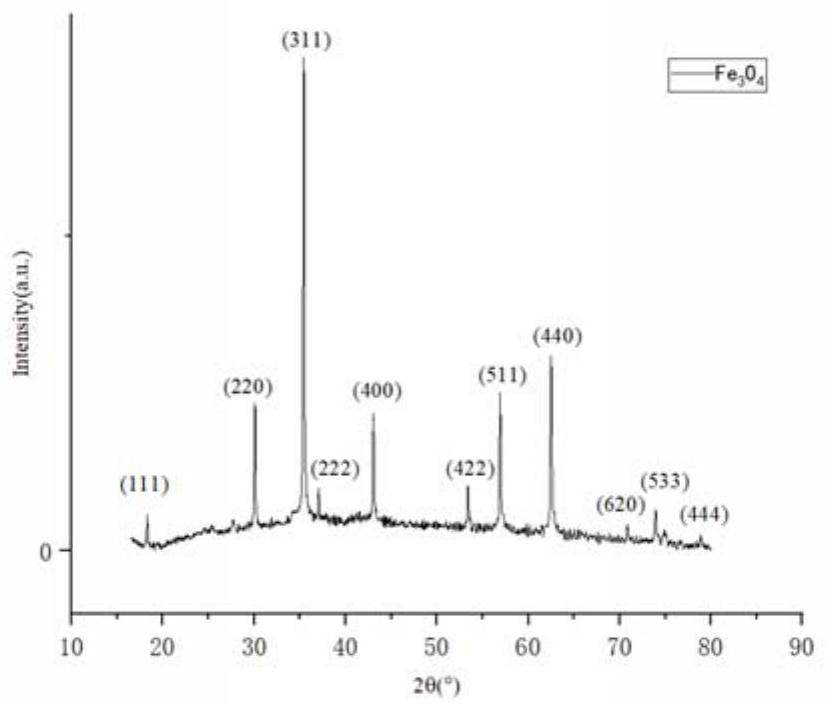

[0080] 1) Preparation of magnetic Fe 3 o 4 The operation process of nanoparticles and amino functionalization is as follows:

[0081] 1-1) Weigh 1.35g FeCl 3 ·6H 2 O, 3.6g NaAc 3H 2O is placed in a polytetrafluoroethylene liner, add 40mL ethylene glycol and 1mL PEG-200, stir evenly to obtain a yellow emulsion, react the reactor at 190°C for 10h, cool to room temperature; wash the product once with ethanol, Wash twice with distilled water and separate to obtain magnetic Fe 3 o 4 Nanoparticles;

[0082] 1-2) Prepare Fe from 1-1) 3 o 4 Disperse the nanoparticles in 60mL of distilled water, add 3mL of 3-aminopropyltriethoxysilane, heat up to 140°C with protective gas argon and reflux for 23h, wash with distilled water once, and separate to obtain aminated magnetic Fe 3 o 4 Nanoparticles.

[0083] 2) Aminated magnetic Fe 3 o 4 The operation process of nano...

Embodiment 2

[0100] A preparation method for highly stable magnetically immobilized laccase, comprising the following steps:

[0101] 1) Preparation of aminated magnetic Fe 3 o 4 The operation process of nanoparticles is as follows:

[0102] 1-1) Weigh 1.35g FeCl 3 ·6H 2 O, 3.6g NaAc 3H 2 O is placed in a polytetrafluoroethylene liner, add 40mL ethylene glycol and 1mL PEG-200, stir evenly to obtain a yellow emulsion, react the reactor at 220°C for 10h, cool to room temperature; wash the product once with ethanol, Wash twice with distilled water and separate to obtain magnetic Fe 3 o 4 Nanoparticles;

[0103] 1-2) Prepare Fe from 1-1) 3 o 4 Disperse the nanoparticles in 60mL of distilled water, add 3mL of 3-aminopropyltriethoxysilane, heat up to 130°C with protective gas argon and reflux for 20h, wash with distilled water once, and separate to obtain aminated magnetic Fe 3 o 4 Nanoparticles.

[0104] 2) The operation process of immobilized laccase is as follows:

[0105] 2-1) t...

Embodiment 3

[0112] A preparation method for highly stable magnetically immobilized laccase, comprising the following steps:

[0113] 1) Preparation of aminated magnetic Fe 3 o 4 The operation process of nanoparticles is as follows:

[0114] 1-1) Weigh 1.35g FeCl 3 ·6H 2 O, 3.6g NaAc 3H 2 O is placed in a polytetrafluoroethylene liner, add 40mL ethylene glycol and 1mL PEG-200, stir evenly to obtain a yellow emulsion, react the reactor at 160°C for 19h, cool to room temperature; wash the product once with ethanol, Wash twice with distilled water and separate to obtain magnetic Fe 3 o 4 Nanoparticles;

[0115] 1-2) Prepare Fe from 1-1) 3 o 4 Disperse the nanoparticles in 60mL of distilled water, add 3mL of 3-aminopropyltriethoxysilane, heat up to 120°C with protective gas argon and reflux for 26h, wash with distilled water once, and separate to obtain aminated magnetic Fe 3 o 4 Nanoparticles.

[0116] 2) The operation process of immobilized laccase is as follows:

[0117] 2-1) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com