Preparation method of PERC solar cell

A solar cell and thickness control technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of battery conversion efficiency drop, oxide layer damage, PN junction exposure, etc., to improve conversion efficiency, reduce leakage, and high The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

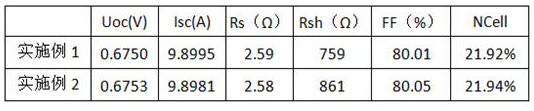

Examples

example 2

[0033] The preparation method of the high-efficiency PERC solar cell in this embodiment is as follows:

[0034] Texture making: 1000 pieces of P-type 1-3Ω.cm silicon wafers are selected for cleaning, texturing, pickling, water washing and drying, the weight loss is controlled to 0.3g, and the reflectivity is controlled to 9.5%;

[0035] Diffusion: Diffusion is performed on the textured silicon wafer at low pressure, the square resistance is controlled at 95Ω / □, and the junction depth is controlled at 240nm;

[0036] Laser SE: Laser doping is carried out using the DR laser machine, and the rear resistance of SE is controlled at 50Ω / □;

[0037] Chain oxidation: Oxidize the silicon wafer after SE, the thickness of the oxide film is controlled at 20nm, and the temperature is 520°C;

[0038] Ozone: The ozone concentration is controlled at 50ppm;

[0039] Remove back PSG: use HF to remove back PSG;

[0040] Alkali etching and polishing: use sodium hydroxide and additives to perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com