Preparation method of high-conductivity solid-state battery electrolyte for energy storage charging system battery

A solid-state electrolyte and charging system technology, applied in the field of preparation of solid-state battery electrolyte, can solve the problems of low conductivity of battery electrolyte and insufficient preparation process, achieve clear and sharp diffraction peaks, and improve the effect of ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

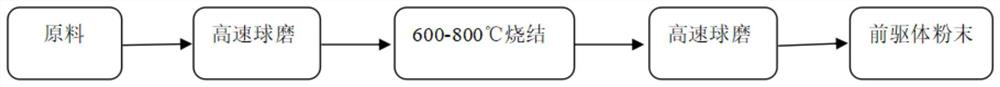

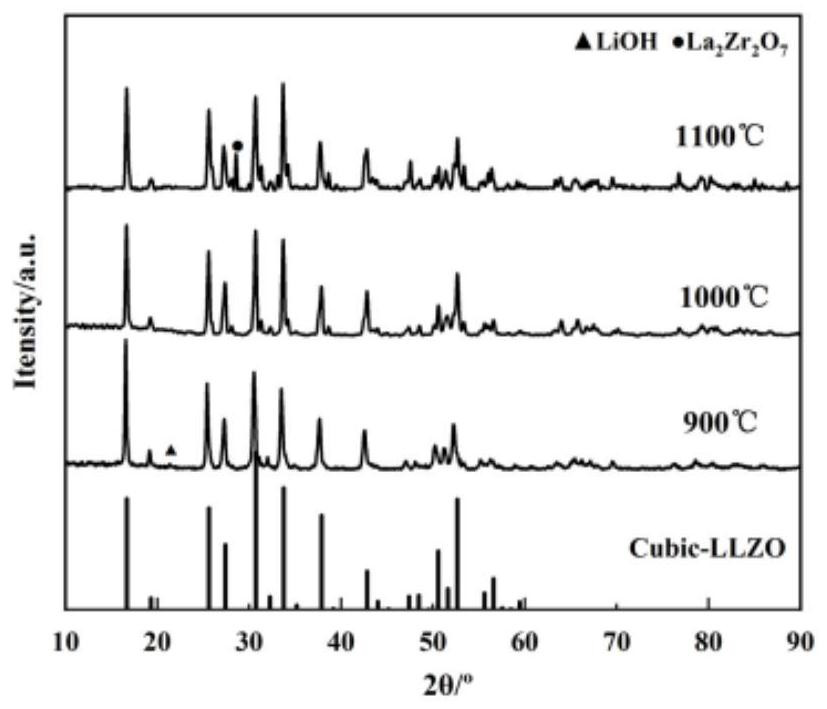

[0030] Such as Figure 1 ~ Figure 2 Shown, a kind of preparation method of high-conductivity solid-state battery electrolyte for battery of energy storage charging system comprises the following steps:

[0031] A. Select La 2 o 3 as la 3+ source, due to La 2 o 3 Chemically unstable in air, easy to absorb H 2 O reacts to form La(OH) 3 , so La 2 o 3 Put it into the furnace and heat it at 900°C for 12h. Lithium hydroxide monohydrate (LiOH·H 2 O), ZrO 2 respectively as Li + Source, Zr 2+ source, in order to avoid volatilization loss of Li element during high-temperature calcination, so an excess of 10% lithium oxide was added for mixing to make up for the loss of Li element, and then LiOH·H 2 O, La 2 o 3 , ZrO 2 The corresponding masses of the three raw materials are weighed according to the substance ratio of 7:3:2. Put the three weighed materials into a high-speed ball mill ball mill tank with balls, the ratio of balls to materials is 10:1, add isopropanol as a ...

Embodiment 2

[0042] A method for preparing a high-conductivity solid-state battery electrolyte for an energy storage charging system battery, comprising the following steps:

[0043] A. Select La 2 o 3 as la 3+ source, due to La 2 o 3 Chemically unstable in air, easy to absorb H 2 O reacts to form La(OH) 3 , so La 2 o 3 Put it into the furnace and heat it at 1000°C for 12h. Lithium carbonate (LiCO 3 ), ZrO 2 respectively as Li + Source, Zr 2+ Source, in order to avoid volatilization loss of Li element during high temperature calcination, so an excess of 10% LiCO was added 3 Mixing is performed to compensate for the loss of Li elements, and then the LiCO 3 , La 2 o 3 , ZrO 2 The corresponding masses of the three raw materials are weighed according to the substance ratio of 7:3:2. Put the three weighed materials into a high-speed ball mill ball mill tank with ball materials, the ratio of ball materials to 10:1, use isopropanol as a solvent, control the ball milling speed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com