Film bulk acoustic resonator with passivation layer and preparation method thereof

A thin-film bulk acoustic wave and passivation layer technology, applied in electrical components, impedance networks, etc., can solve problems such as poor protection effect, and achieve the effects of improving temperature stability, improving mechanical strength, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

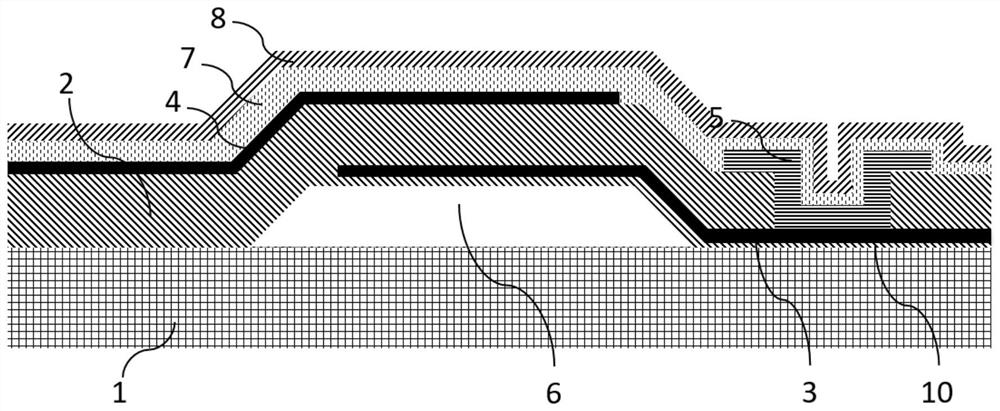

[0047] Such as Figure 2-Figure 13 As shown, a method for preparing a thin film bulk acoustic resonator with a passivation layer according to the present invention comprises the following steps:

[0048] S1, cleaning the substrate 1 formed by a high-resistance silicon wafer with a suitable thickness for standby, the thickness of the substrate 1 can be between hundreds of microns to thousands of microns;

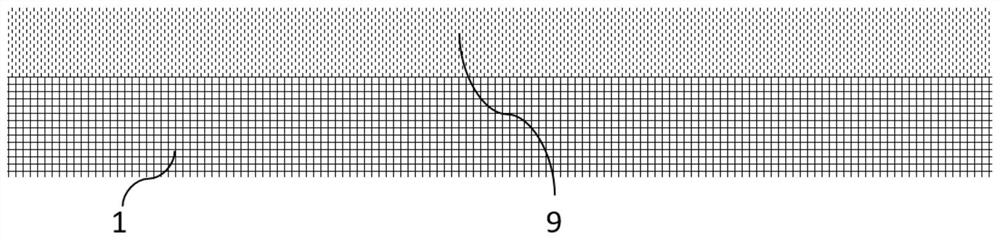

[0049] S2. After the substrate 1 with a specific thickness is obtained, it is oxidized, and then a layer of silicon dioxide is grown on the surface of the substrate 1 as a sacrificial layer 9. The thickness of the sacrificial layer 9 can be between several hundred nanometers and several microns. between;

[0050] S3. Process the sacrificial layer 9 through photolithography, that is, process the sacrificial layer 9 by coating photoresist, mask exposure, dry etching, and removing photoresist, and finally process the sacrificial layer 9 into an isosceles trapezoidal cross secti...

example 1

[0062] The method for forming the bottom electrode 3 or top electrode 4 in steps S5 and S7 can also be to perform metal evaporation or sputtering first, and then perform photolithography and dry etching to form the bottom electrode 3 or top electrode 4 .

[0063] Variation 2

[0064] The bottom electrode 3 is connected to the electrical signal, and the top electrode 4 is connected to the ground.

[0065] working principle

[0066] When there is a potential difference between the bottom electrode 3 and the top electrode 4 , the electric field between them can effectively excite acoustic resonance in the piezoelectric layer 2 . The introduction of the air cavity 6 forms a metal-air interface between the substrate 1 and the oscillation area of the resonator, which can effectively confine the sound wave in the piezoelectric oscillation stack and maintain the mechanical strength of the resonator. In addition, the double-layer passivation layer composed of the first passivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com