Weather-resistant hard coat composition for metal, cured product and coated metal substrate

A weather resistance and composition technology, applied in metal layered products, devices for coating liquid on the surface, coatings, etc. The effect of improving manufacturing efficiency, excellent surface hardness, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

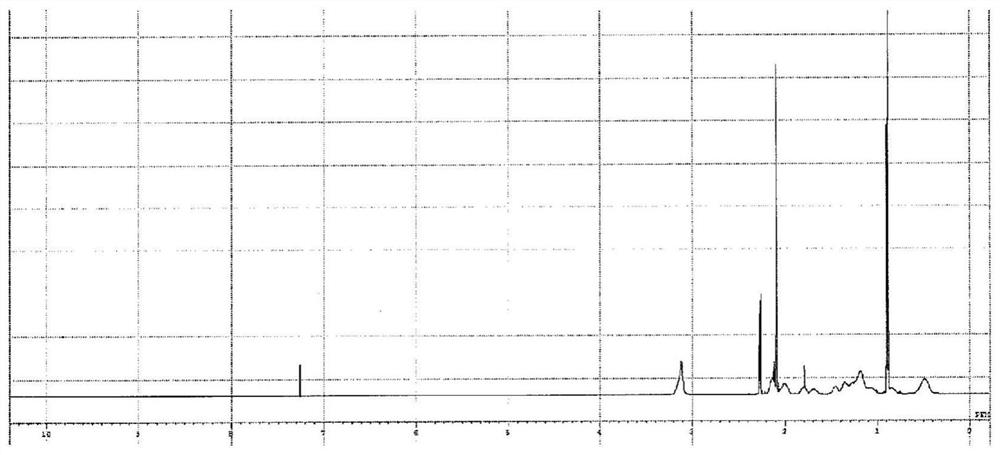

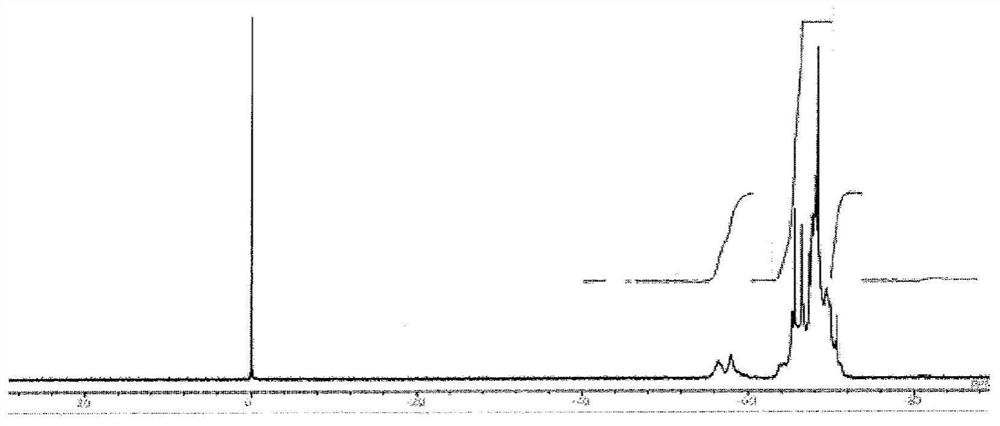

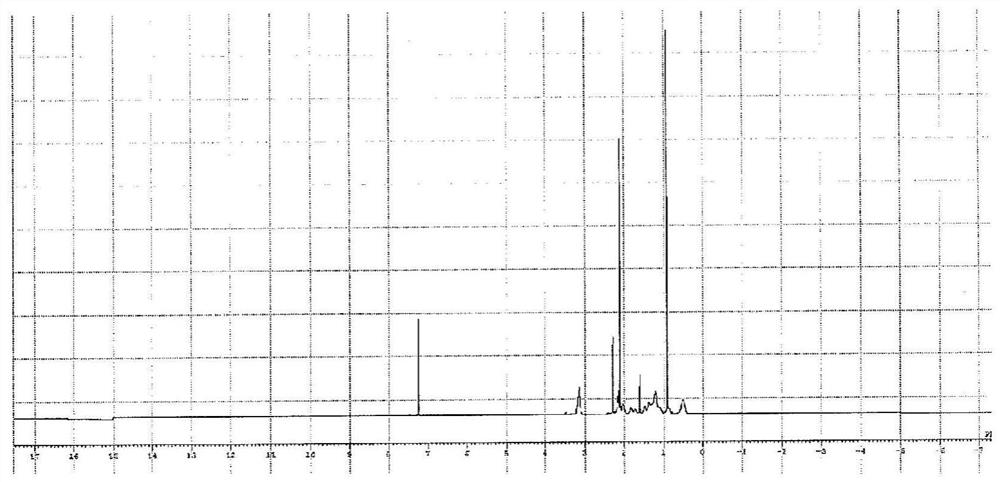

[0388] Production Example 1: Production of epoxy group-containing low molecular weight polyorganosilsesquioxane

[0389] In a 1000ml flask (reaction vessel) equipped with a thermometer, a stirring device, a reflux condenser and a nitrogen inlet tube, add 277.2mmol (68.30g) of 2-(3,4-epoxycyclohexyl) ethyl Trimethoxysilane, 3.0 mmol (0.56 g) of phenyltrimethoxysilane and 275.4 g of acetone, the temperature was raised to 50°C. After adding 7.74 g of a 5% potassium carbonate aqueous solution (2.8 mmol as potassium carbonate) to the thus obtained mixture over 5 minutes, 2800.0 mmol (50.40 g) of water was added over 20 minutes. It should be noted that during the addition, the temperature did not increase significantly. Thereafter, polycondensation reaction was performed for 5 hours under nitrogen flow while maintaining 50°C.

[0390] Thereafter, while cooling the reaction solution, 137.70 g of methyl isobutyl ketone and 100.60 g of 5% saline were injected. This solution was tr...

manufacture example 2

[0393] Production Example 2: Production of Epoxy Group-Containing High Molecular Weight Polyorganosilsesquioxane (1)

[0394] In a 1,000-ml flask (reaction vessel) equipped with a thermometer, a stirring device, a reflux condenser, and a nitrogen gas introduction tube, the epoxy-containing low-molecular-weight polyorganosilsesquioxane obtained in Production Example 1 was added under nitrogen flow. The mixture (75g), with respect to the net content (56.2g) of low molecular weight polyorganosilsesquioxane containing epoxy group, add the potassium hydroxide of 100ppm (5.6mg), and add the water of 2000ppm (112mg), After heating at 80°C for 18 hours, a sample was taken and the molecular weight was measured. As a result, the number average molecular weight Mn rose to 6000, then cooled to room temperature, 300 mL of methyl isobutyl ketone was added, and 300 mL of water was added, and washed with water repeatedly. As a result of concentration after removing the alkali component, 74....

manufacture example 3

[0397] Production Example 3: Production of epoxy group-containing high molecular weight polyorganosilsesquioxane (2)

[0398] In a 1,000-ml flask (reaction vessel) equipped with a thermometer, a stirring device, a reflux condenser, and a nitrogen gas introduction tube, the epoxy-containing low-molecular-weight polyethylene oxide obtained by the same method as in Production Example 1 was added under nitrogen flow. A mixture of organosilsesquioxanes (75 g), with respect to the net content (56.2 g) of epoxy-containing low molecular weight polyorganosilsesquioxanes, 100 ppm (5.6 mg) of potassium carbonate was added, and 2000 ppm ( 112mg) of water was sampled at 80°C for 18 hours and the molecular weight was measured. As a result, the number average molecular weight Mn rose to 4800, then cooled to room temperature, 300mL of methyl isobutyl ketone was added, and 300mL of Water, as a result of concentration after repeated washing with water to remove the alkali component, 74.5 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com