Preparation method of high-strength composite hydrogel

A composite hydrogel, high-strength technology, applied in the field of self-healing hydrogel preparation, can solve the problems of poor strength and toughness, limit the application range of hydrogel, weak external mechanical force resistance, etc., and achieve mild reaction conditions , Excellent mechanical properties, good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

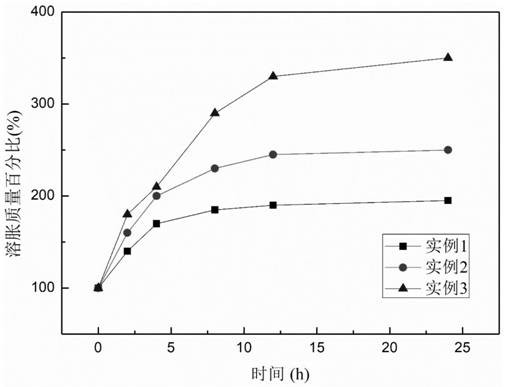

Embodiment 1

[0024] The specific preparation method is: (1) Weigh 0.02mol 1-vinylimidazole and 0.01mol 1,6-dibromohexane into a flask containing 15mL of methanol, stir and mix evenly under N 2 Under protection, the mixture was stirred and reacted in an oil bath at 60°C for 15 hours, and left to cool at room temperature. After cooling, the reaction product was slowly dropped into a sufficient amount of ether, washed, filtered, and vacuum-dried at 40°C to obtain a crosslinking agent A.

[0025] (2) Weigh 1mmol of 3-[2-(methacryloxy)ethyl]trimethylammonium]propane-1-sulfonate (MPS), 4mmol of 1-vinyl-3-ethylimidazole Bromide salt (VIM), 2 mg photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure-2959) and 0.013 g crosslinker A were added to 1.5 g water. Stir magnetically for 10 minutes, blow nitrogen gas into the system after the components are uniformly dispersed, seal and ultrasonically treat until mixed evenly, transfer to a UV light box, irradiate and react under 29...

Embodiment 2

[0028] The specific preparation method is as follows: (1) Weigh 0.02mol 1-vinylimidazole and 0.01mol 1,4-dibromobutane into a flask containing 15mL N,N-dimethylformamide, magnetically stir and mix evenly, N 2 Under protection, the mixture was stirred and reacted in an oil bath at 60°C for 24 hours, and left to cool at room temperature. After cooling, the reaction product was slowly dropped into a sufficient amount of petroleum ether, washed, filtered, and vacuum-dried at 40°C to obtain a crosslinking agent A.

[0029] (2) Weigh 2mmol of 3-[2-(methacryloyloxy)ethyl]trimethylammonium]propane-1-sulfonate (MPS), 4mmol of 1-vinyl-3-butylimidazole Bromide salt, 2 mg photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure-2959) and 0.02 g crosslinker A were added to 1.5 g water. Stir magnetically for 10 minutes, blow nitrogen gas into the system after the components are uniformly dispersed, seal and ultrasonically treat until mixed evenly, transfer to a UV lig...

Embodiment 3

[0032] The specific preparation method is: (1) Weigh 0.02mol 1-vinylimidazole and 0.01mol 1,10-dibromodecane into a flask containing 15mL N,N-dimethylformamide, magnetically stir and mix evenly, and N 2 Under protection, the mixture was stirred and reacted in an oil bath at 60°C for 24 hours, and left to cool at room temperature. After cooling, the reaction product was slowly dropped into a sufficient amount of petroleum ether, washed, filtered, and vacuum-dried at 40°C to obtain a crosslinking agent A.

[0033] (2) Weigh 2mmol of 3-[2-(methacryloyloxy)ethyl]trimethylammonium]propane-1-sulfonate (MPS), 3mmol of 1-vinyl-3-hexylimidazolium bromide Salt, 2 mg photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure-2959) and 0.01 g crosslinker A were added to 1.5 g water. Stir magnetically for 10 minutes, blow nitrogen gas into the system after the components are uniformly dispersed, seal and ultrasonically treat until mixed evenly, transfer to a UV light b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com