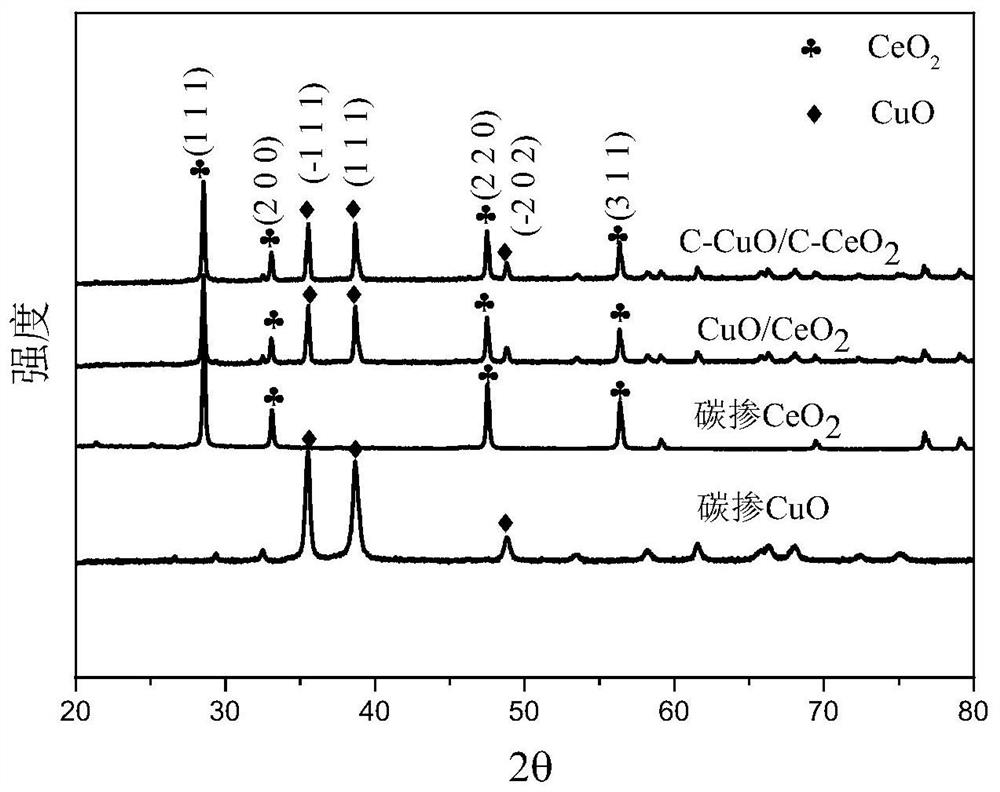

Method for preparing CuO/CeO2 composite material by utilizing aquatic plant enrichment and application of CuO/CeO2 composite material

A technology of composite materials and aquatic plants, applied in the application field of photocatalytic carbon dioxide conversion to methanol, to achieve the effects of improving utilization rate, enhancing photocatalytic activity, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First weigh 7.59g of cerium nitrate and 4.22g of copper nitrate and put them into different beakers with 500ml water respectively. 7 and 5 (pH regulator is NaOH or HNO 3 ), then use deionized water to clean a certain amount of Hollow lotus and water hyacinth, put the washed Hollow lotus and water hyacinth into cerium nitrate and copper nitrate solution for adsorption for 6 hours respectively, and measure Ce 4+ 、Cu 2+ The adsorption amounts are 23mg / g and 32mg / g respectively (measured by inductively coupled plasma-atomic emission spectrometry ICP-AES, there will be some mineral elements in aquatic plants, but these mineral elements are extremely small and unstable, and they are sensitive to light. Catalytic activity and experimental results have no effect); the above-mentioned absorbed Herb Alternatus and water hyacinth are taken out, the cerium salt and copper salt on the surface are cleaned with deionized water, the roots are cut off, then dried at 80 ° C, and ground ...

Embodiment 2

[0036] First weigh 7.56g of cerium nitrate and 4.25g of copper nitrate and put them into different beakers with 500ml of water respectively. 7 and 5, then use deionized water to clean a certain amount of Hollow Lotus and Water Hyacinth, put the washed Hollow Lotus and Water Hyacinth into cerium nitrate and copper nitrate solutions for adsorption for 2 hours, and measure Ce 4+ 、Cu 2+ The adsorption amounts of the two are 8mg / g and 10mg / g respectively; take out the above-mentioned absorbed lotus and water hyacinth, wash the cerium salt and copper salt on the surface with deionized water, cut off the root, then dry it at 80°C, and grind it into Powder: Weigh 1g of water hyacinth powder and 1g of lotus root powder and dissolve them in 100ml of water, adjust the pH value to 7, stir well, heat in a water bath at 60°C for 1 hour, and centrifuge and dry the obtained solution; the above dry mixture Transfer to a crucible, heat in a muffle furnace to 500°C for 2 hours, and finally grin...

Embodiment 3

[0038] First weigh 7.53g of cerium nitrate and 4.26g of copper nitrate and put them into different beakers with 500ml water respectively. 7 and 5, then use deionized water to clean a certain amount of Hollowflower and water hyacinth, put the washed hollow lotus and water hyacinth into cerium nitrate and copper nitrate solutions for adsorption for 4 hours, and measure Ce 4+ 、Cu 2+ The adsorption amounts of 15mg / g and 21mg / g respectively; take out the above-mentioned absorbed lotus and water hyacinth, wash the cerium salt and copper salt on the surface with deionized water, cut off the root, then dry at 80 °C, and grind into Powder: Weigh 1g of water hyacinth powder and 1g of lotus root powder and dissolve them in 100ml of water, adjust the pH value to 7, stir well, heat in a water bath at 60°C for 1 hour, and centrifuge and dry the obtained solution; the above dry mixture Transfer to a crucible, heat in a muffle furnace to 500°C for 2 hours, and finally grind to obtain carbon-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com