Combined catalyst and method for treating nitrogen-containing volatile organic compound pollutants

A technology of volatile organic and combined catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

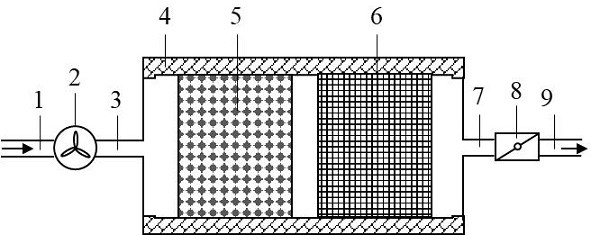

[0031] like figure 2 The selective oxidation-total oxidation integrated reaction device shown includes a fixed bed reactor 4, a catalyst bed I5 and a catalyst bed II6; inside the cavity.

[0032] The device also includes an air inlet pipeline 1, a fan 2 and a pipeline I3; the fan 2 communicates with the inlet pipeline 1 and the pipeline I3 respectively, and further, the pipeline I3 communicates with the fixed bed reactor 4.

[0033] The device also includes a pipeline II7, a one-way valve 8 and an exhaust pipeline 9; the one-way valve 8 communicates with the pipeline II7 and the exhaust pipeline 9 respectively, and further, the pipeline II7 is connected to the fixed-bed reactor 4 connected.

[0034] This embodiment is carried out under a specific gas flow direction, and the gas flow direction is: inlet pipeline 1→fan 2→pipeline I3→fixed bed reactor 4→catalyst bed layer I5→catalyst bed layer II6→pipeline II7→one-way valve 8→Exhaust pipeline 9.

Embodiment 2

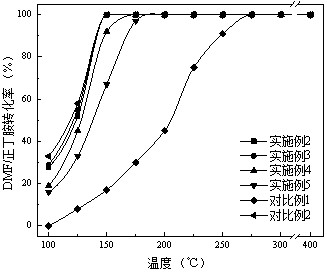

[0035] Example 2 Cu / ZSM-5 and Pt / MnO 2 Catalyst treatment of DMF and toluene gas

[0036] Preparation of Cu / ZSM-5 and Pt / MnO by Vacuum Impregnation 2 Catalyst, the mass ratio of Cu to carrier is 0.04-0.15:1, SiO of ZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio is 25; the mass ratio of Pt to carrier is 0.001-0.05:1.

[0037] Catalyst activity evaluation uses the selective oxidation-total oxidation integrated reaction device of Example 1, using 7.5wt.%Cu / ZSM-5 (7.5wt.% refers to the mass ratio of Cu to ZSM-5) as the selective oxidation catalyst, Set in the catalyst bed I described in Example 1; using 1.0wt%Pt / MnO 2 As a complete oxidation catalyst, it is installed in the catalyst bed II described in Example 1.

[0038] Pollutants and products are detected online by GC-7890B gas chromatography and Fourier transform infrared spectroscopic gas analyzer. The pollutants are DMF and toluene gas, the concentration is 500 ppm, the gas flow rate is 200 ml / min, and the space ve...

Embodiment 3

[0040] Example 3 Cu / porous Ce-Zr solid solution support and Pt / MnO 2 Catalyst treatment of DMF and toluene gas

[0041] Catalysts loaded with different amounts of Cu in porous Ce-Zr solid solution were prepared by hydrothermal method, and the molar ratio Cu:Ce:Zr=4-10:80:20. A 0.5-1.0wt.% Pt / MnO2 catalyst was prepared by vacuum impregnation. Using 10wt.%Cu / Ce-Zr solid solution catalyst as selective oxidation catalyst, using Pt / MnO 2 As a complete oxidation catalyst, other activity evaluation conditions were the same as in Example 2.

[0042] Experimental results such as Figure 3-5 As shown, under the air reaction atmosphere, toluene and DMF were completely decomposed at 200 °C, and the nitrogen selectivity was 94% at 250 °C. After the catalyst was operated at 250°C for 100 hours, the activity did not decrease significantly, that is, the catalyst had good stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com