A kind of fluorine-containing aromatic hydrocarbon wastewater treatment process

A technology for wastewater treatment and aromatic hydrocarbons, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Efficiency and other issues, to achieve the effect of improving wastewater treatment efficiency, improving efficiency, and improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

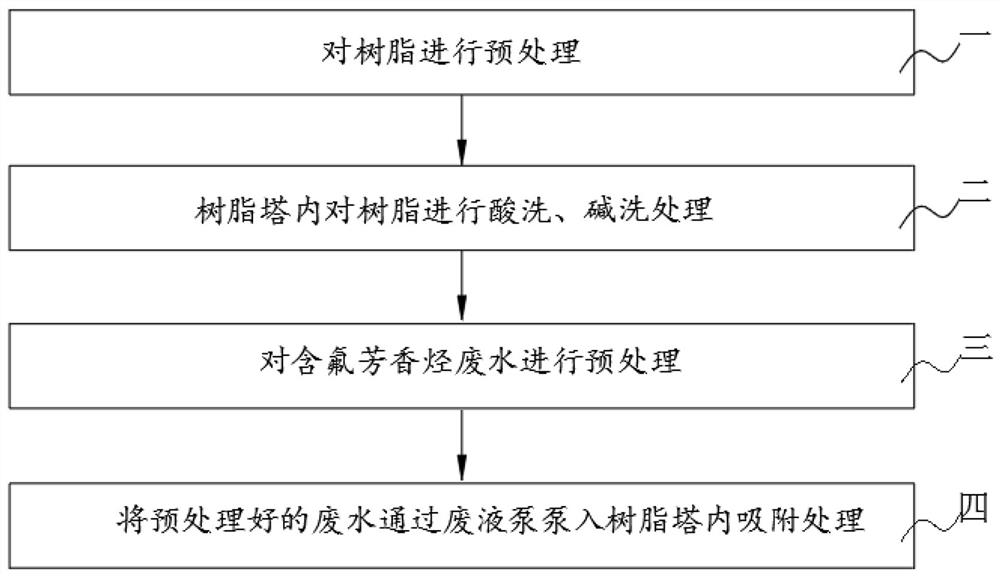

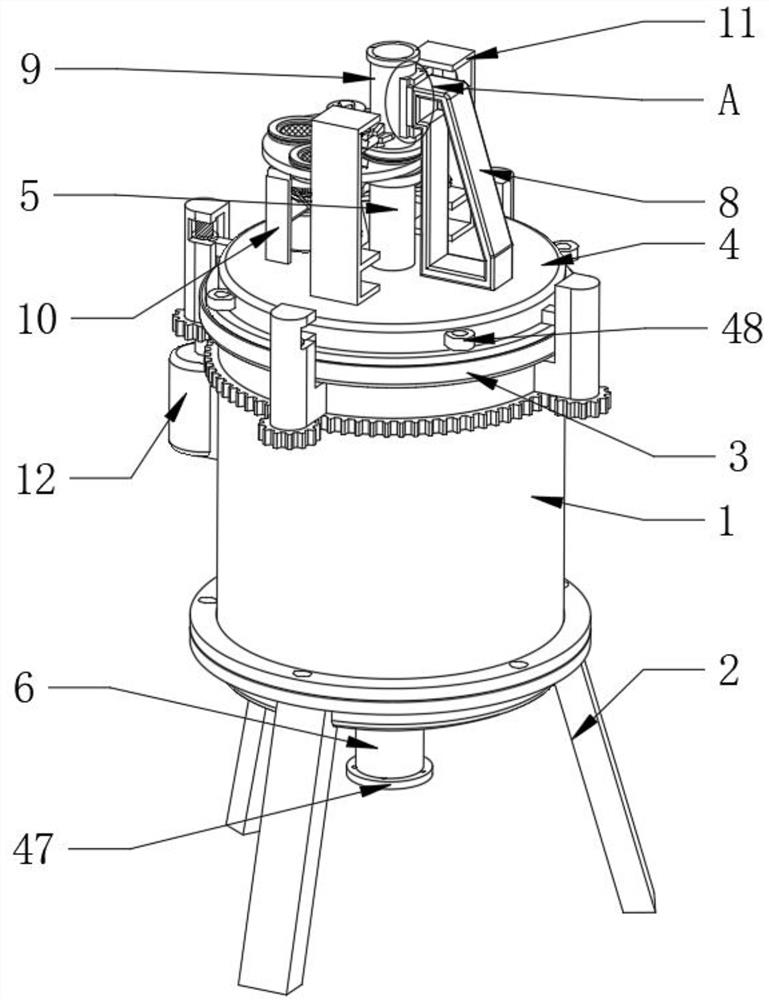

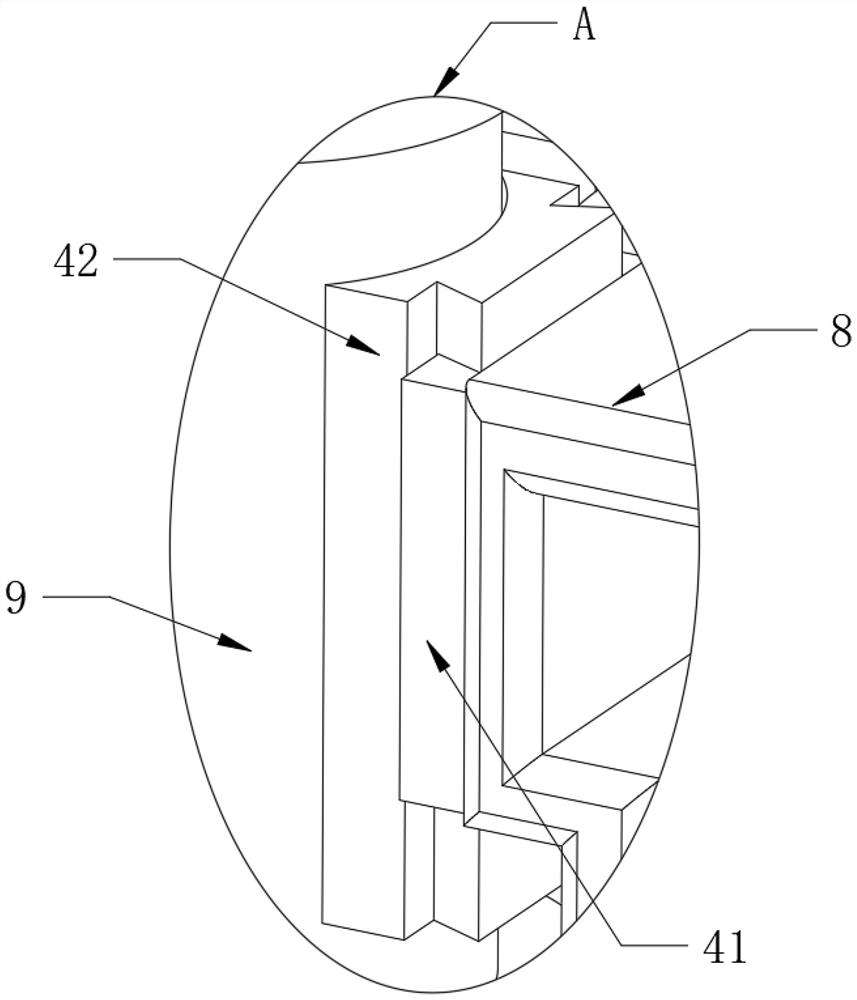

[0045] In the specific implementation process, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a fluorine-containing aromatic hydrocarbon wastewater treatment process is completed by using an ion exchange resin tower that facilitates automatic replacement of the filter screen. The treatment process includes the following steps:

[0046] 1. Pretreatment of the resin:

[0047] 1) Use acetone to wash the resin. You can choose to reflux wash the resin in a Soxhlet extractor for about 8 hours, and then wash off the acetone with water;

[0048] 2) Wash the resin repeatedly with dilute hydrochloric acid solution, and then wash it with water;

[0049] 3) After drying, dry at 50°C until constant weight and fill in the resin tower.

[0050] 2. Further processing of the resin in the resin tower:

[0051] 1) Firstly, pass HCl solution with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com