A kind of refining method of methoxyamine hydrochloride

A kind of technology of methoxyamine hydrochloride and refining method, applied in the refining field of methoxyamine hydrochloride, can solve problems such as affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

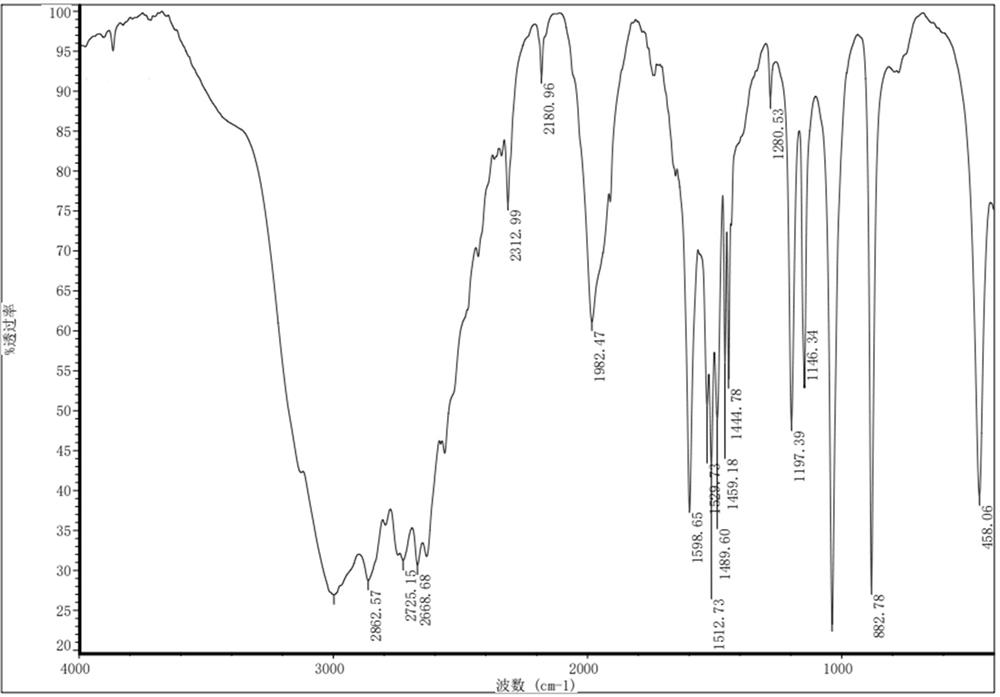

Image

Examples

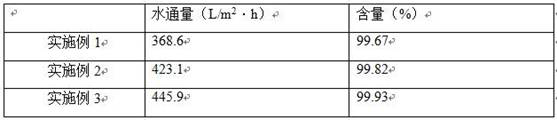

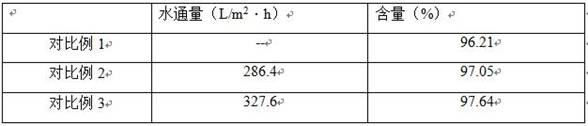

Embodiment 1

[0028] A kind of purification method of methoxyamine hydrochloride, its scheme is:

[0029] The reaction solution in the 100kg reaction tower still is pumped into the reboiler through the reaction tower pump and heated and circulated to 50 ° C, and then enters the rectification tower 1 to carry out the vacuum rectification reaction, and the distillate flows into the reaction tower distillation tank through the secondary condensation at the top of the tower. , the distillation tower still liquid is pumped into the tower still liquid separator for stratification, and the lower layer is the methoxyamine hydrochloride solution; then the lower layer methoxyamine hydrochloride solution is pumped into the concentration tower, and after the concentration The tower circulating pump and the reboiler of the concentration tower are circulated and heated to 60 °C and concentrated to 40%, then add 80 kg of organic solvent, stir and mix evenly, and then cool down to 30 °C through a heat excha...

Embodiment 2

[0038] A kind of purification method of methoxyamine hydrochloride, its scheme is:

[0039]The reaction liquid in the 200kg reaction tower still is pumped into the reboiler through the reaction tower pump and heated and circulated to 60 ° C, then enters the rectification tower 1 to carry out the vacuum rectification reaction, and the distillate flows into the reaction tower distillation tank through the secondary condensation at the top of the tower. , the distillation tower still liquid is pumped into the tower still liquid separator for stratification, and the lower layer is the methoxyamine hydrochloride solution; then the lower layer methoxyamine hydrochloride solution is pumped into the concentration tower, and after the concentration The tower circulating pump and the reboiler of the concentration tower are circulated and heated to 70 ℃ and concentrated to 50%, then add 100 kg of organic solvent, stir and mix evenly, and then cool down to 35 ℃ through a heat exchanger, an...

Embodiment 3

[0048] A kind of purification method of methoxyamine hydrochloride, its scheme is:

[0049] The reaction liquid in the 300kg reaction tower still is pumped into the reboiler through the reaction tower pump to be heated and circulated to 80 ° C, and then enters the rectification tower 1 to carry out the vacuum rectification reaction, and the distillate flows into the reaction tower distillation tank through the secondary condensation at the top of the tower. , the distillation tower still liquid is pumped into the tower still liquid separator for stratification, and the lower layer is the methoxyamine hydrochloride solution; then the lower layer methoxyamine hydrochloride solution is pumped into the concentration tower, and after the concentration The tower circulating pump and the reboiler of the concentration tower are circulated and heated to 80 °C and concentrated to 60%, then add 160 kg of organic solvent, stir and mix evenly, and then cool down to 40 °C through a heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com