Long-acting anti-freezing flame-retardant additive for water and preparation method thereof

A technology of flame retardant additives and antifreeze, which is applied in the direction of fireproof coatings, etc., can solve the problems of swelling and corrosion of rubber sealing rings of pipe fittings, weakening of the effect of antifreeze additives, and easy corrosion, etc., and achieves low biological toxicity, large reduction, and corrosion resistance low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

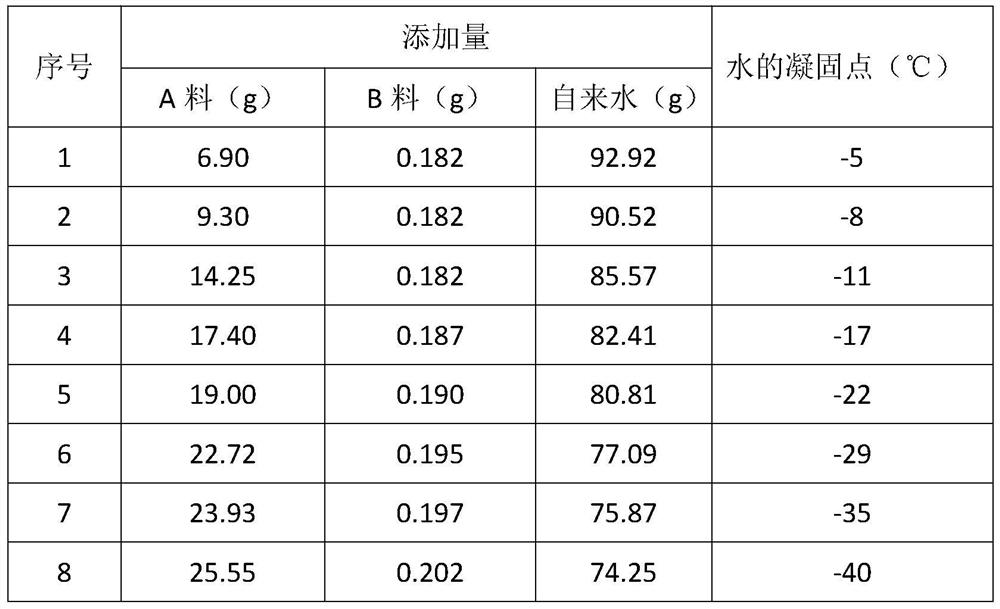

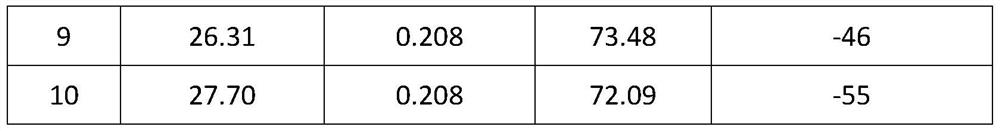

Image

Examples

Embodiment 1

[0026] The water is used for long-term anti-freeze-retardant additives, composed of A material and B, and the b is solid, and B is a liquid state;

[0027] A material is included in 100 ga, containing 86.4 g of antifreeze, 13.6 g of urea, the antifreeze consisting of 76.89 g of magnesium chloride and potassium formate;

[0028] The B material is in 100 GB of material, including 24.5 g of a bactericide, 1.26 g of a bactericide, 74.24 g of deionized water, the corrosion inhibitor from 8.0 g of water-soluble imidazoline, 7.5 g 2-hydroxyphosphonic acid (HPAA) 2.5 g of thiazol sodium salts (DTNA), 4.5 g of sodium benzoate and sodium molybdate composition, the fungicide is isothiazolinone.

[0029] The preparation method of long-term anti-freeze flame retardant additives for water, including the following steps:

[0030] (1) Preparation of A,

[0031] According to each 100 gA, 86.4 g, urea 13.6 g, urea 13.6.8 g, urea 13.6g, then 13.6 g of magnesium chloride (magnesium chloride 76.89 g, ...

Embodiment 2

[0036] The water is used for long-term anti-freeze-retardant additives, composed of A material and B, and the b is solid, and B is a liquid state;

[0037] A material is included in every 100 ga, including 87.8 g of antifreeze, 12.2 g of urea, and the antifreeze consist of 78.14 g of magnesium chloride and 9.66 g of potassium acetate;

[0038] The B material is in 100 Gb, a component containing 24.5 g, a bactericidal 1.26 g, deionized water 74.24 g, and the corrosion inhibitor consists of 8.0 g of water soluble imidazoline, 7.5 g 2-hydroxyphosphonic acid, 2.5g. The thiadiazole salt, 4.0 g of sodium benzoate and 2.5 g of sodium molybdate, the fungicide is isothiazolinone.

[0039] The preparation method of long-term anti-freeze flame retardant additives for water, including the following steps:

[0040] (1) Preparation of A,

[0041] According to each 100 ga material, 87.4 g, urea 12.2g, 12.66 g of acetate, 12.66 g of acetate, 12.2 g of urea (magnesium chloride 78.14 g, potassium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com