High-temperature adjacent metal heat treatment device and method

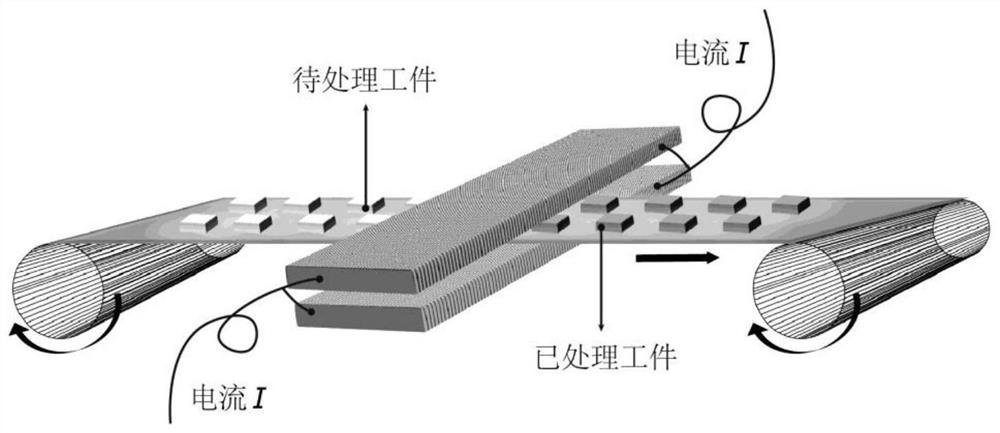

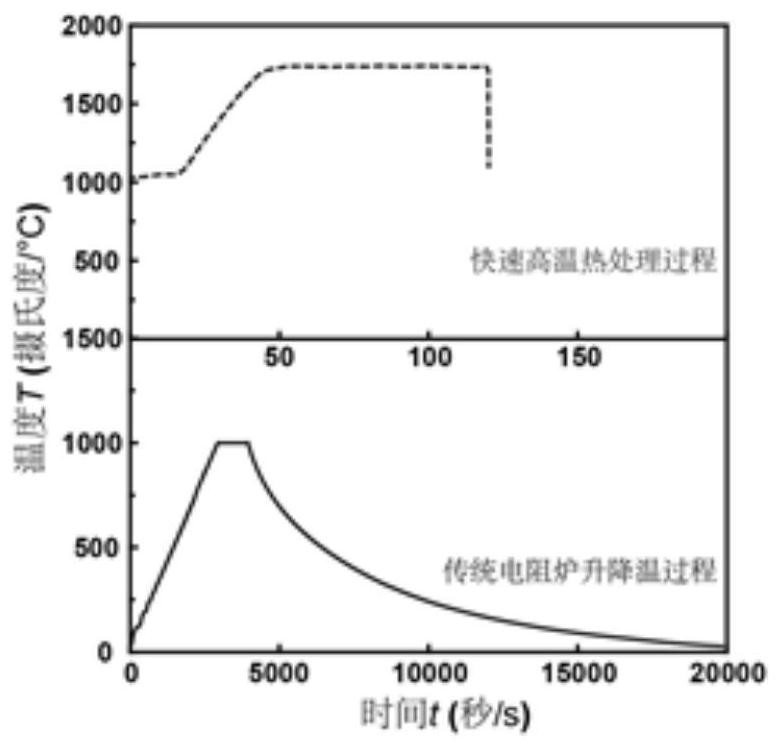

A technology for metal heat treatment and heat treatment equipment, which is applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., and can solve problems such as high power consumption, unsuitable for wide application, and inability to achieve batch processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

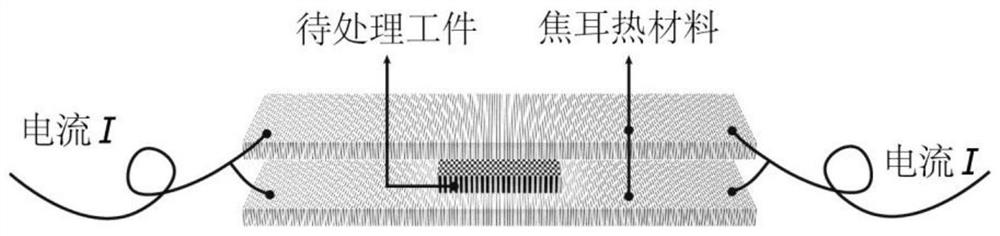

[0044] Embodiment 1: the tempering treatment of No. 45 steel, the quenched raw material of No. 45 steel is placed in image 3 In the typical device diagram shown in the Joule heat plate, the plate is heated to 725°C by electricity, and the workpiece is taken out after holding the heat for 10s, that is, the high temperature tempering process of No. 45 steel is completed. The tempered No. 45 steel obtained has the same properties as Consistent performance with conventional electric furnace heat treatment.

Embodiment 2

[0045] Embodiment 2: The aging treatment of aluminum alloy, the green embryo of 7000 series aluminum alloy is placed in image 3 In the typical device diagram shown in the Joule heat plate, the plate is heated to 425°C with electricity, and the workpiece is taken out after holding the heat for 10s, that is, the aging process of the 7000 series aluminum alloy is completed. The obtained 7000 series aluminum alloy has the same properties as the traditional electric furnace. Heat treatment for consistent strength.

Embodiment 3

[0046] Embodiment 3: the solid solution strengthening of titanium alloy, the annealing raw material TC4 of titanium alloy is placed in image 3 Between the Joule-heated pole plates shown in the typical device diagram, the pole plates are heated to 725°C with electricity, and the workpiece is taken out after holding the heat for 10s, that is, the solid solution strengthening process of the titanium alloy TC4 is completed. The obtained TC4 titanium alloy has the same properties as the traditional electric furnace. Heat treatment for consistent strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com