Asymmetric semi-solid electrolyte, preparation method and metal lithium secondary battery

A semi-solid, asymmetric technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of low lithium ion transmission rate, low mechanical strength, and increased interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

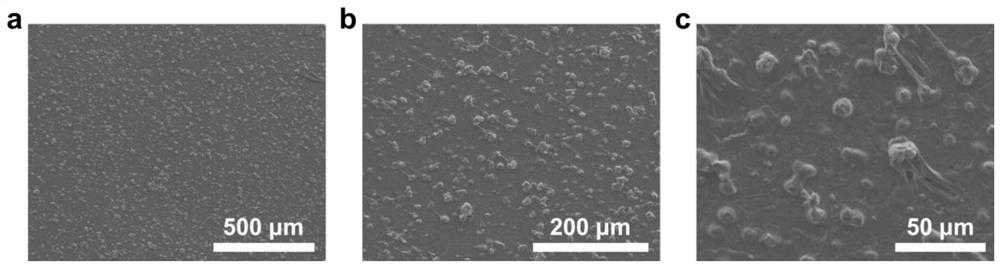

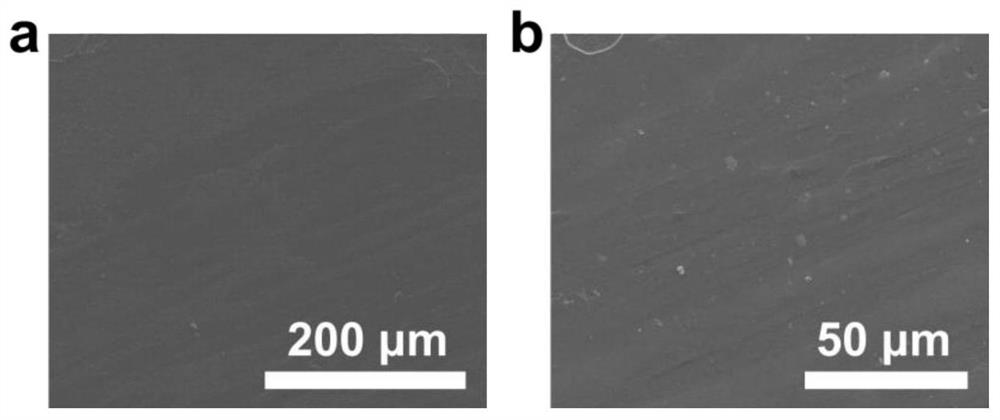

[0046] Weigh 1.0 g of PVDF-HFP solid powder into 9.0 g of acetone and stir until dissolved. Afterwards, 0.4 g of polyethylene glycol-400 was added as a pore-forming agent, and stirred evenly. Then use a scraper to scrape it on one side of a 10 cm*20 cm conventional diaphragm, and take it out after volatilizing the solvent at 60 °C for 30 min. Then put it in 300 mL of anhydrous methanol and let it stand for 5.0 h to remove the pore-forming agent polyethylene glycol 400, then place it again at 60°C for 2.0 h to evaporate the solvent, and then take it out to obtain a solid electrolyte facing the negative side Floor. After that, weigh 1.0 g of PEO with a molecular weight of 500,000 and add it to 9.0 mL of acetonitrile. After it is fully dissolved, weigh LiTFSI into it according to the ratio of EO:Li=18:1, and stir until dissolved. Afterwards, 0.4 g of LLZO was weighed and added to the above solution, and stirred until completely dispersed. Next, scrape-coat the prepared dispers...

Embodiment 2-4

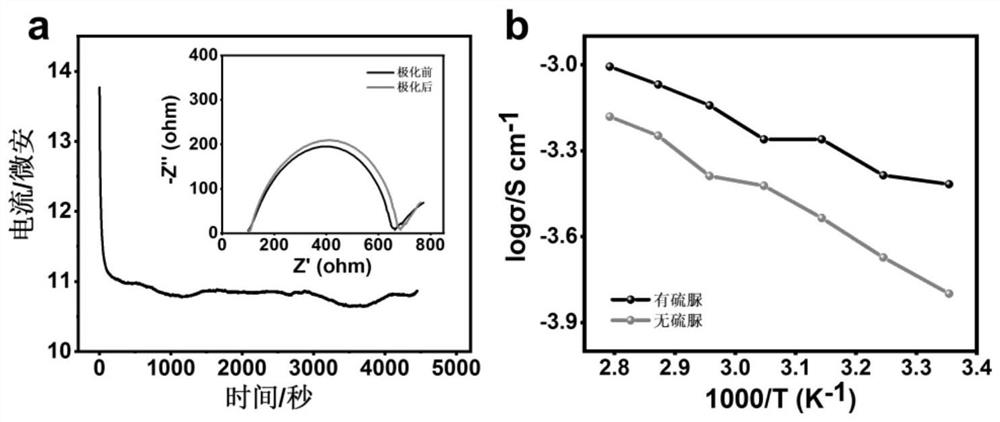

[0048] An asymmetric composite solid-state electrolyte was prepared in the same manner as in Example 1, except that the ratios of EO:Li were controlled at 20:1, 8:1, and 4:1, respectively. Afterwards, the obtained asymmetric separator was punched into a disc with a diameter of 16 mm, and an electrolyte solution containing 1.0 mg / mL thiourea with a mass fraction of 10% was dropped on the side facing the negative electrode to obtain an asymmetric composite membrane. electrolyte. Afterwards, it was assembled with metal lithium and lithium iron phosphate cathode to form an actual battery for testing, and its charge-discharge specific capacity and cycle stability were tested at 0.1 C, and the test temperature was 25 °C.

Embodiment 5-7

[0050] An asymmetric composite solid electrolyte was prepared in the same manner as in Example 1, except that LLZO was replaced by LATP, LAGP, and LSPS with the same mass fraction. Afterwards, the obtained asymmetric separator was punched into a disc with a diameter of 16 mm, and an electrolyte solution containing 1.0 mg / mL thiourea with a mass fraction of 10% was dropped on the side facing the negative electrode to obtain an asymmetric composite membrane. electrolyte. Afterwards, it was assembled with metal lithium and lithium iron phosphate cathode to form an actual battery for testing, and its charge-discharge specific capacity and cycle stability were tested at 0.1 C, and the test temperature was 25 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com