Cryopump assembly regeneration method for neutral beam input system

A technology of input system and cryopump, which is applied in pumps, pump control, liquid displacement machinery, etc., and can solve problems such as inability to adapt to regeneration of cryopump components and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

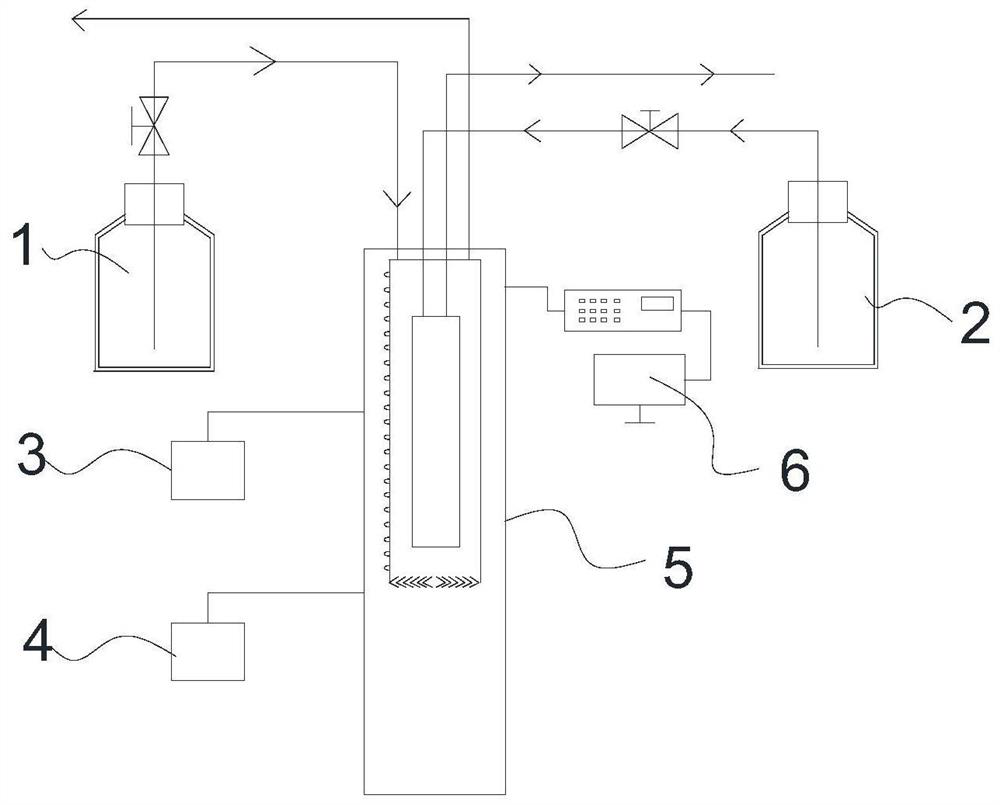

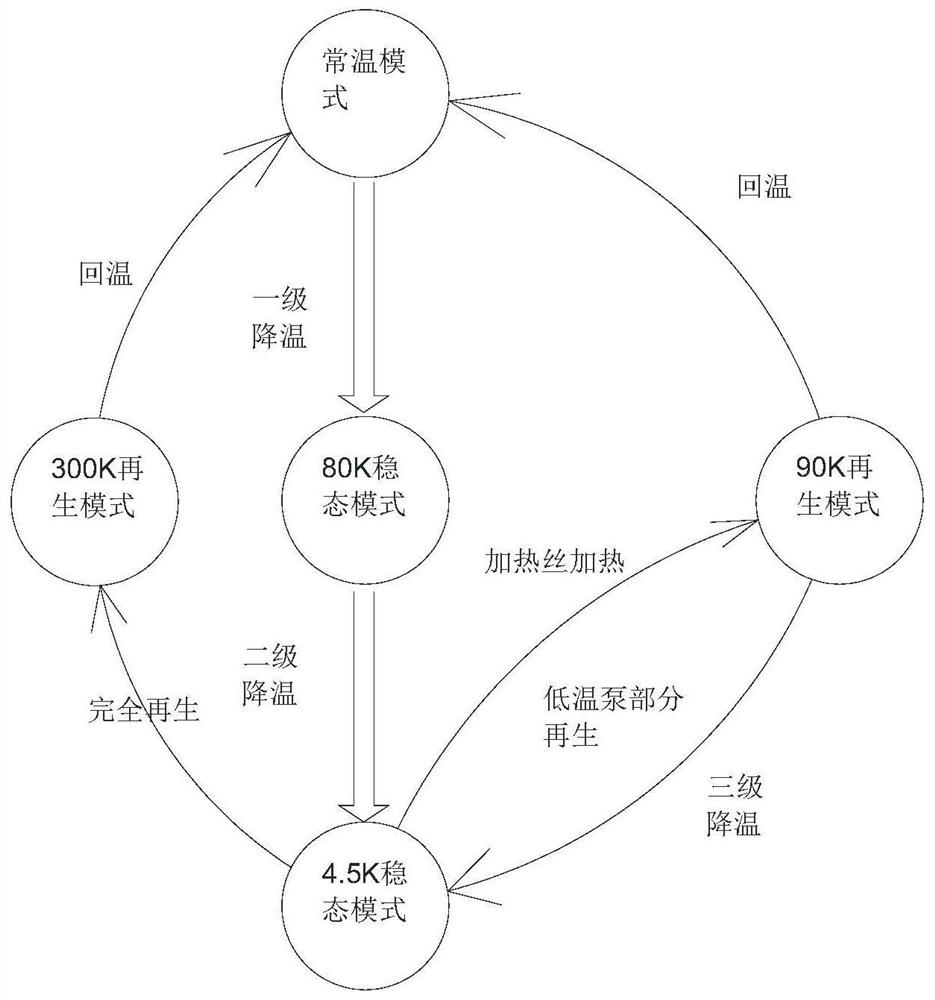

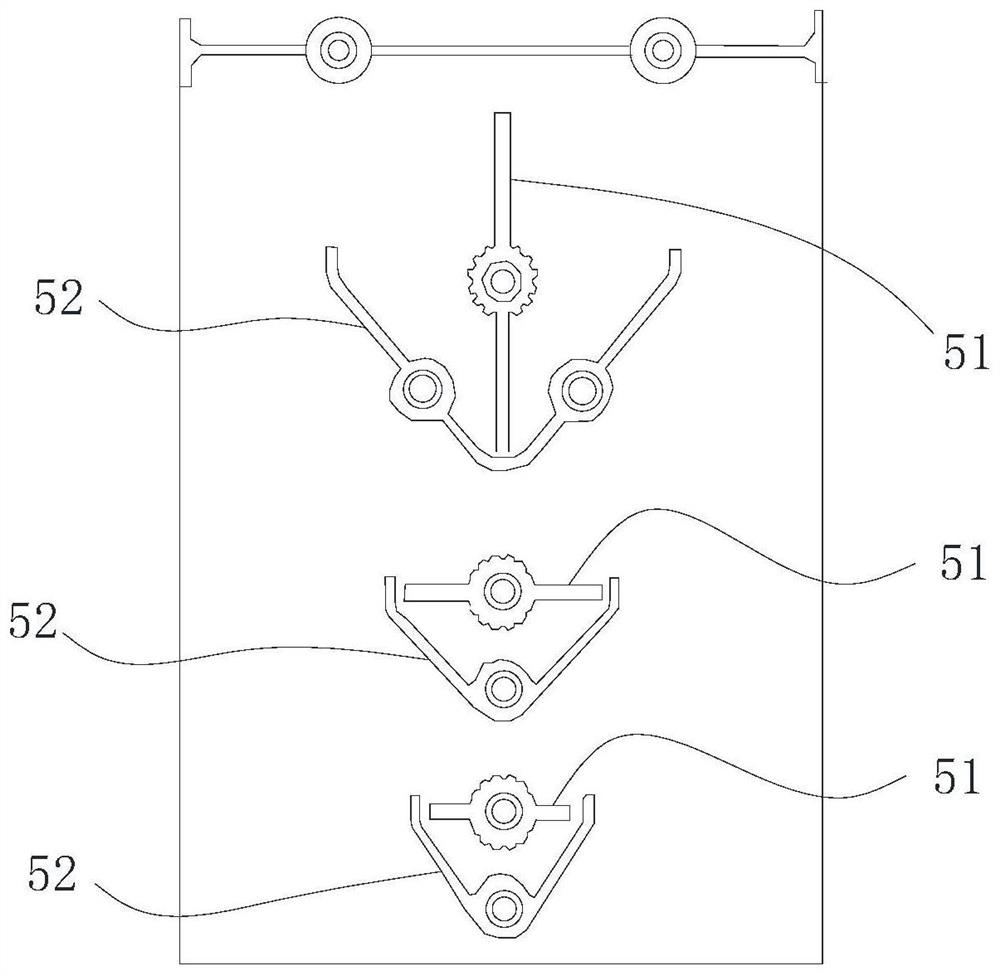

[0034] Such as figure 1 As shown, the cryopump assembly for the neutral beam input system includes a liquid nitrogen Dewar 1, a liquid helium Dewar 2, a molecular pump 3, a Roots pump 4, a cryopump 5, and a temperature measurement and control device 6, combined with image 3As shown, the liquid nitrogen Dewar 1 is connected to the radiation protection baffle 52 in the cryopump 5 through a liquid nitrogen tube, and is used to cool the radiation protection baffle 52, and the liquid helium Dewar 2 is connected to the cryogenic pump 5 through a liquid helium tube. The low-temperature adsorption surface 51 in the pump 5 is connected to cool the low-temperature adsorption surface 51. There are activated carbon and heating wires on the low-temperature adsorption surface 51. The activated carbon is used for adsorption, and the heating wire is used for heating. The temperature measurement and control device 6 is connected to the heating wire. The anti-radiation baffle 52 and the low-te...

Embodiment 2

[0079] In this embodiment, on the basis of the first embodiment above,

[0080] The complete regeneration includes the following steps:

[0081] (1) Close the liquid helium valve;

[0082] (2) Close the liquid nitrogen valve;

[0083] (3) Heating the low-temperature adsorption surface from 51 to 300K, and monitoring the heating process through the temperature sensor set on the panel;

[0084] (4) During heating to 300K, the temperature rises, and the gas adsorbed by activated carbon is gradually released;

[0085] (5) Open the air pump along with the heating process, gradually extract the released gas, and monitor the air extraction process by monitoring the pressure change;

[0086] (6) After the air extraction is completed, close the air extraction valve, and the complete regeneration is completed.

[0087] Whether to choose partial regeneration or partial regeneration followed by full regeneration depends on the usage; that is, partial regeneration can be performed alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com