Attached bioprosthetic valve and preparation method thereof

A bio-valve, fit-type technology, applied in the field of biomedical engineering, can solve problems such as unfavorable endothelial cell adhesion and proliferation, affecting the application effect of heart valves, etc., to improve biocompatibility, maintain aesthetics, and high mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a fitting biological valve, comprising the following steps:

[0035] S1. Cutting the decellularized animal valve to obtain animal valve slices 10;

[0036] S2. The polylactic acid fabric woven from the first polylactic acid yarn is fully soaked in the vascular endothelial growth factor solution, and after freeze-drying, the drug controlled release fabric 20 is obtained;

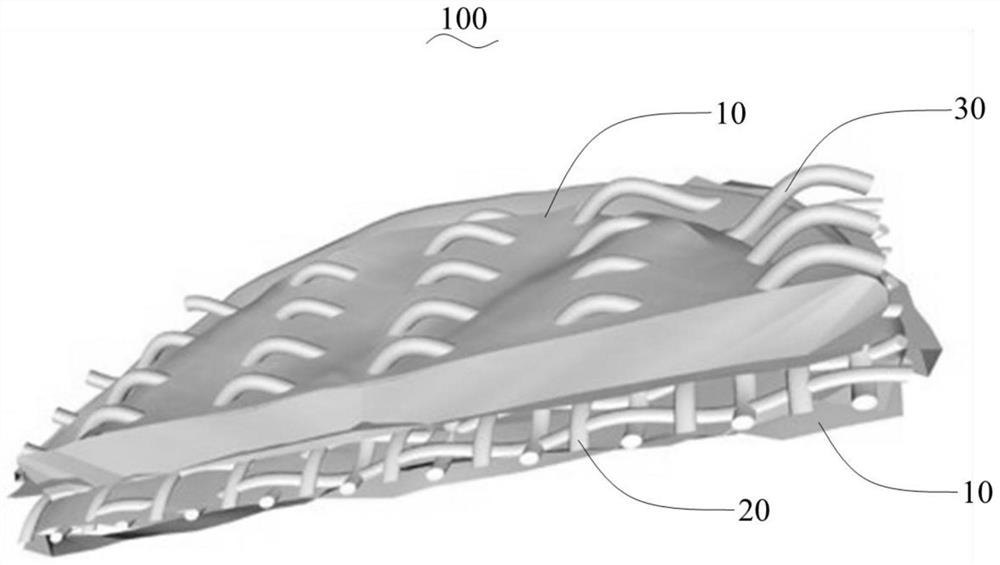

[0037]S3. Cutting the drug controlled release fabric obtained in step S2 so that its size is consistent with the animal valve slice obtained in step S1; and then attaching the two animal valve slices to the drug controlled release fabric respectively The two sides of the valve are bonded with medical bio-glue to obtain a bio-valve stent;

[0038] S4. Acupuncture the biological valve support obtained in step S3 to form a number of holes on the surface of the biological valve support;

[0039] S5. Thread the second polylactic acid yarn 30 sequentially into ...

Embodiment 1

[0049] This embodiment provides a method for preparing a conformable biological valve 100, which includes the following steps:

[0050] S1. Segmentation of animal valves

[0051] Turn on the Leica CM3050S cryostat, adjust the temperature of the sample stage to -40°C, take a fresh decellularized porcine aortic valve as the sample to be cut, blot the surface moisture with filter paper, and measure its thickness with a spiral micrometer; Place the sample to be cut on the sample stage of the cryostat, fix it with embedding agent around the sample to be cut, freeze for 10 minutes, raise the temperature to -15°C, start slicing after 5 minutes, remove the surface embedding agent, and Half of the thickness of the sample to be cut is used as the slice thickness to obtain an animal valve slice 10 with a thickness half of the original thickness of the valve, and save it for future use.

[0052] S2, preparation of drug controlled release fabric

[0053] Soak the polylactic acid fabric i...

Embodiment 2~5

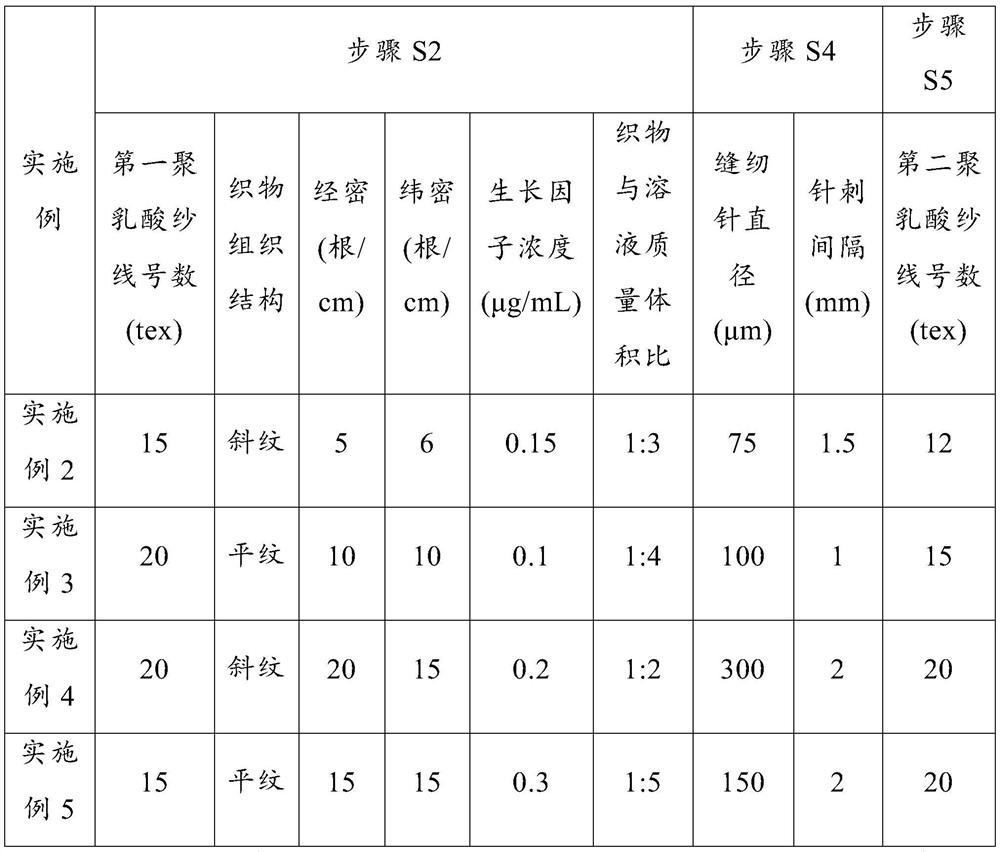

[0063] Embodiments 2 to 5 respectively provide a method for preparing a conformable biological valve. Compared with Embodiment 1, the difference is that the relevant process parameters in steps S2, S4 and S5 are changed, and the remaining steps are the same as those in Embodiment 1. 1 are consistent and will not be repeated here. The parameter values corresponding to each embodiment are shown in Table 1.

[0064] The technological parameter value of table 1 embodiment 2~5

[0065]

[0066] There are certain differences between the mechanical properties and the speed of promoting cell growth of the conforming biological valves of Examples 2-5 prepared according to the above process parameters, indicating that the concentration of growth factors, the warp and weft density of the drug-controlled release fabric and the stitches can be adjusted. The needle spacing regulates the growth rate of cells, and controls the reinforcement effect of the valve by adjusting the sewing ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com