Method for preparing high-purity C16 and C18 normal mono-alkane

A monoalkane, high-purity technology is applied in the field of preparing high-purity C16 and C18 normal monoalkanes, which can solve the problems of high cost of separating monoalkanes, high separation cost, high technical difficulty, etc., and achieves low production cost, high purity, Simple effect of process technology route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

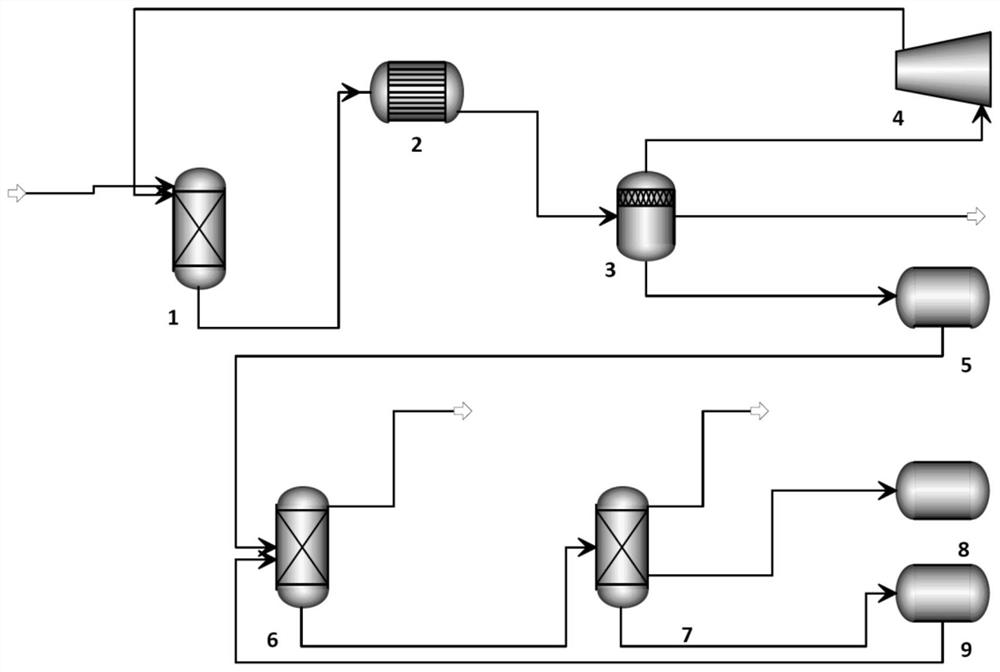

Image

Examples

Embodiment 1

[0036] (1) Modified Al 2 o 3 Preparation of vector

[0037] (1) Dissolve a certain amount of zinc nitrate in deionized water, and load it on Al by impregnation method 2 o 3On the carrier, the loading amount is 1% based on ZnO, dried at 80°C for 12h, and calcined at 550°C for 6h;

[0038] (2) Carry out silicon modification treatment to the sample that step (1) obtains, use tetraethyl orthosilicate as silicon modifier, n-heptane as diluent, the proportioning of modifier and diluent is 9:1 , the sample was impregnated at 30°C for 12 hours, and then baked at 550°C for 6 hours to obtain modified Al 2 o 3 carrier.

[0039] (2) Preparation of hydrogenation catalyst:

[0040] (1) Upper layer catalyst: Ammonium molybdate and nickel nitrate are used as active metal precursors, dissolved in deionized water by complexation, and then the active metals are loaded on the modified Al by co-impregnation. 2 o 3 For the carrier, the content of active metal is calculated as oxide, the lo...

Embodiment 2

[0050] (1) Modified Al 2 o 3 Preparation of vector

[0051] (1) Dissolve a certain amount of magnesium nitrate in deionized water, and load it on Al by impregnation method 2 o 3 On the carrier, the loading amount is 1% based on MgO, dried at 120°C for 6h, and calcined at 550°C for 6h;

[0052] (2) Carry out silicon modification treatment to the sample obtained in step (1), use siloxane as silicon modifier, benzene as diluent, the ratio of modifier to diluent is 8:1, at 60 ℃ Immerse the sample for 3 hours, and then bake it again at 550°C for 6 hours to obtain modified Al 2 o 3 carrier.

[0053] (2) Preparation of hydrogenation catalyst:

[0054] The preparation method of hydrogenation catalyst in the present embodiment is identical with embodiment 1, and difference is only in:

[0055] (1) Upper layer catalyst: the active metal content is calculated as oxide, the loading of nickel oxide is 8%, and the loading of molybdenum oxide is 2%.

[0056] (2) Lower layer catalyst...

Embodiment 3

[0065] (1) Modified Al 2 o 3 Preparation of vector

[0066] (1) Dissolve a certain amount of magnesium nitrate and zinc nitrate in deionized water, and load them on Al by impregnation method 2 o 3 On the carrier, the loading amount is 0.5% as ZnO, 0.5% as MgO, dried at 100°C for 10h, and calcined at 550°C for 6h;

[0067] (2) Carry out silicon modification treatment to the sample that step (1) obtains, use tetraethyl orthosilicate as silicon modifier, cyclohexane as diluent, the proportioning of modifier and diluent is 7:1, The sample was impregnated at 100°C for 1h, and then baked at 550°C for 6h to obtain modified Al 2 o 3 carrier.

[0068] (2) Preparation of hydrogenation catalyst:

[0069] The preparation method of hydrogenation catalyst in the present embodiment is identical with embodiment 1, and difference is only in:

[0070] (1) Upper layer catalyst: the active metal content is calculated as oxide, the loading of nickel oxide is 5%, and the loading of molybden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com