Drag reducer, preparation method of drag reducer, slickwater fracturing fluid and application

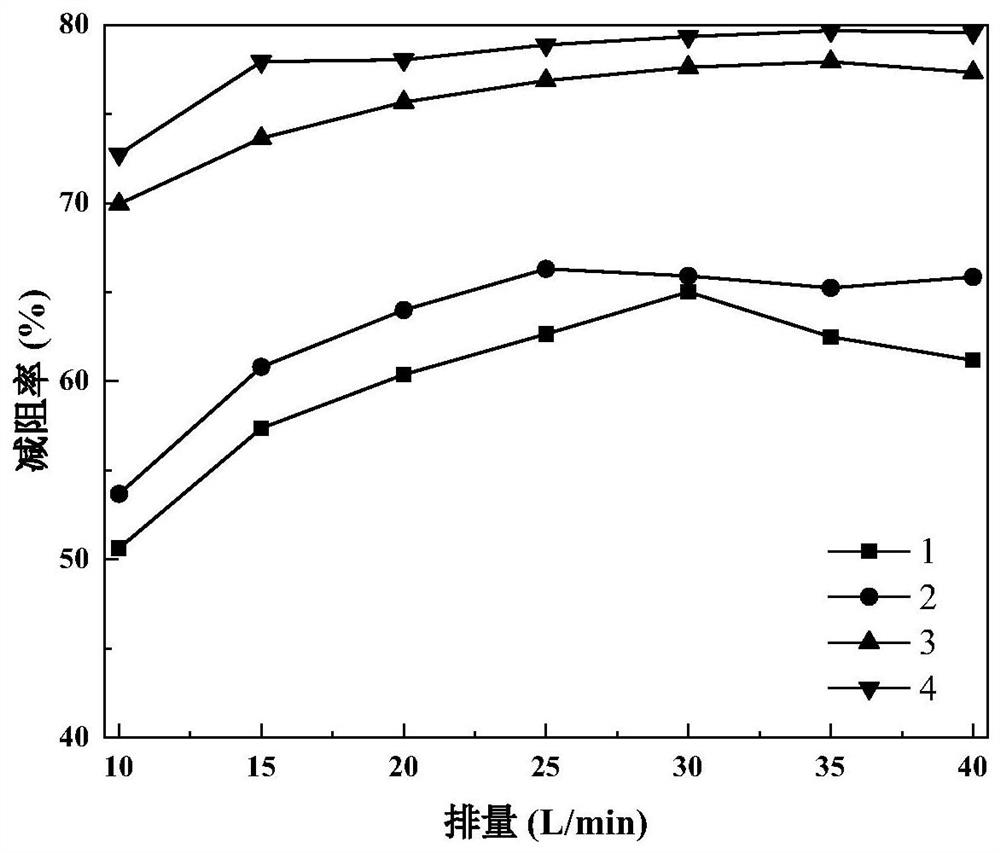

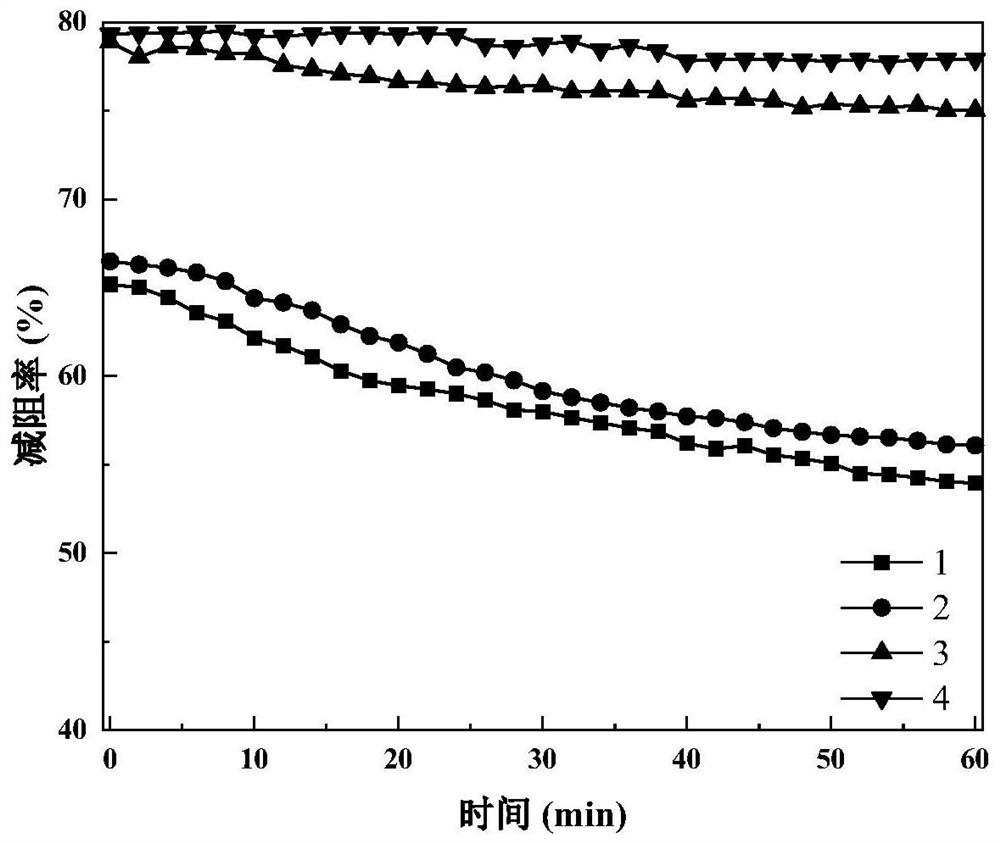

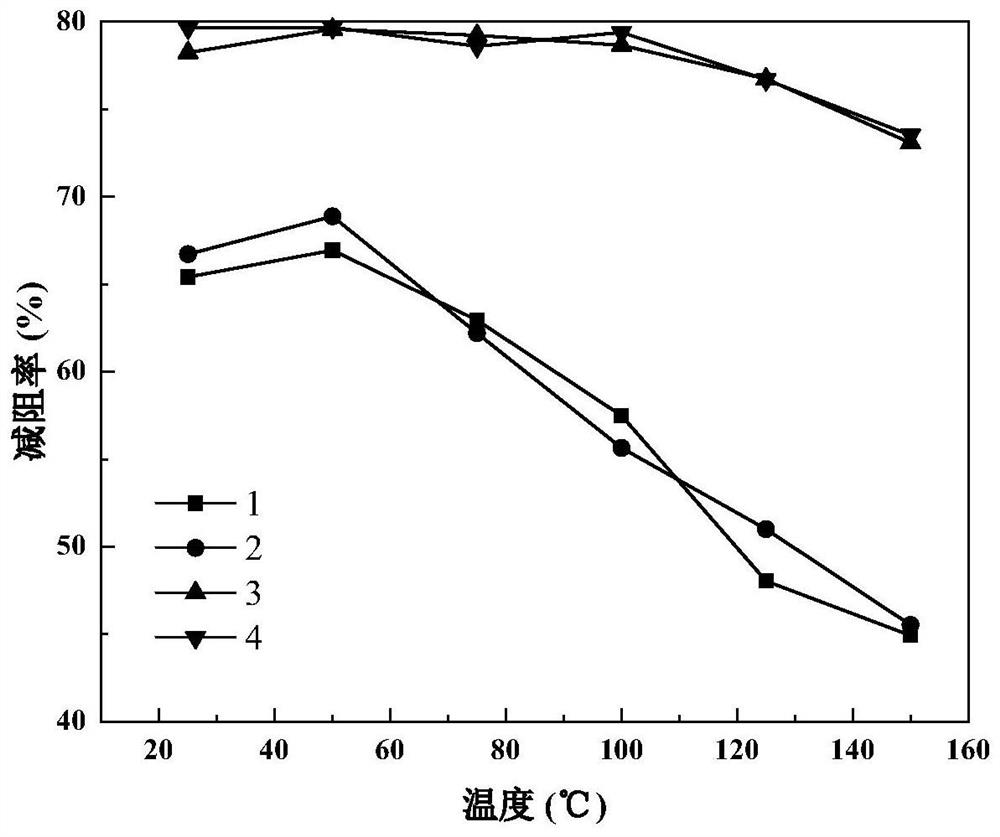

A drag reducing agent and water fracturing technology, applied in the field of fracturing fluid, can solve the problems of polymer chain shear failure, drag reduction rate less than 50%, poor shear resistance effect, etc., to reduce surface tension and improve lubrication. Wet, easy flowback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The second aspect of the present invention provides a method for preparing the aforementioned drag reducer, wherein the preparation method includes:

[0045](1) In the presence of a solvent, contact the nano silicon dioxide with a silane coupling agent with a double bond to carry out the first reaction to obtain modified nano silicon dioxide;

[0046] (2) In the presence of nitrogen and initiator, contact the acrylamide shown in the modified nano-silica, co-dispersant, formula (4) and water for the second reaction, and wash the obtained reaction product , vacuum drying and grinding to obtain the drag reducer;

[0047]

[0048] Wherein, the silane coupling agent with a double bond has a monomer shown in formula (5) or formula (6):

[0049]

[0050] Among them, X 1 selected from -Cl and / or -CH 3 ;

[0051] Among them, X 2 selected from -Cl, -CH 3 、-CH 2 CH 3 and -CH 2 CH 2 OCH 3 one or more of.

[0052] According to the present invention, in step (1), th...

Embodiment 1

[0082] This example is to illustrate the drag reducer prepared by the method of the present invention.

[0083] (1) Dissolve 2.5 g of dried nano silicon dioxide with a particle size of 10-20 nm in 85 g of absolute ethanol, stir and disperse at room temperature for 12 hours to obtain a first mixed solution. Another 0.525g of silane coupling agent γ-methacryloxytrimethoxysilane KH-570 was dissolved in 72.5g of absolute ethanol as a solvent, and stirred at a stirring rate of 375r / min at a temperature of 25°C To clarification, the second mixed solution was obtained. Mix the first mixed solution and the second mixed solution to obtain a mixed solution, adjust the pH of the mixed solution to 3.75 with 1mol / L oxalic acid, place the mixed solution in an oil bath at 75°C and stir for 3.75 hours; Rotary evaporation at ℃, washing with absolute ethanol for 3-4 times, and vacuum drying at 95℃ for 30 hours to obtain KH-570 modified nano-silica;

[0084] (2) Add 2.5 g of auxiliary dispersant...

Embodiment 2

[0089] This example is to illustrate the drag reducer prepared by the method of the present invention.

[0090] (1) Dissolving 2 g of dried nano-silica with a particle size of 10-20 nm in 80 g of absolute ethanol, stirring and dispersing at room temperature for 12 hours, to obtain a first mixed solution. Another 0.05g of silane coupling agent vinyltriethoxysilane was dissolved in 70g of solvent absolute ethanol, and stirred at a temperature of 25°C and a stirring rate of 350r / min until clear to obtain a second mixed solution . Mix the first mixed solution and the second mixed solution to obtain a mixed solution, adjust the pH of the mixed solution to 4 with 1mol / L oxalic acid, place the mixed solution in an oil bath at 80°C and stir for 4 hours; and put the reaction product at 60°C Rotary evaporation under the conditions, washing with absolute ethanol for 3-4 times, and vacuum drying at a temperature of 90°C for 24 hours to obtain vinyltriethoxysilane-modified nano-silica;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com