A kind of high oxygen index low smoke halogen free cable material and preparation method thereof

A high oxygen index and cable material technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of slow flame retardancy of carbon crusts, etc., to improve oxygen index, acceleration efficiency, and improve resistance flammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

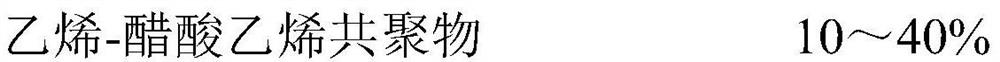

Method used

Image

Examples

Embodiment 1

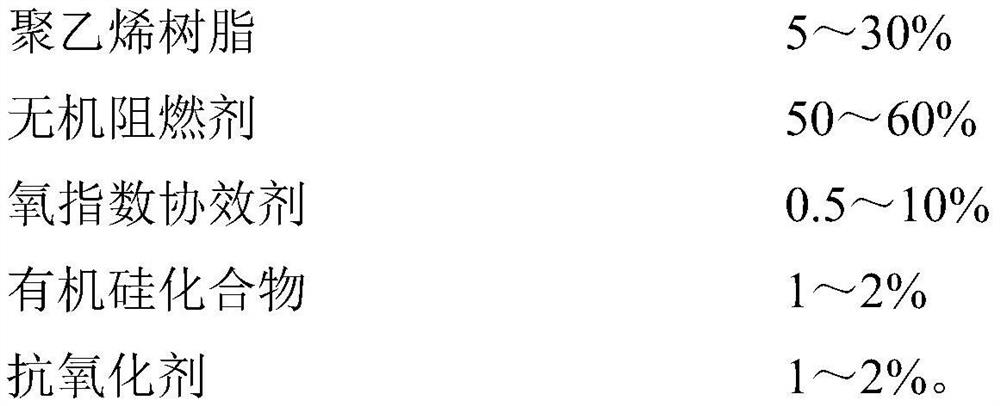

[0041] The organic phosphinate, nitrogen-based compound and organosilicon compound were added to the high-speed mixer according to the proportions of Example 1 in Table 1, and the oxygen index synergist was obtained after stirring uniformly.

Embodiment 2

[0043] The organic phosphinate, nitrogen-based compound and organosilicon compound were added to the high-speed mixer according to the ratio of Example 2 in Table 1, and the oxygen index synergist was obtained after stirring uniformly.

Embodiment 3

[0045] The organic phosphinate, nitrogen-based compound and organosilicon compound were added to the high-speed mixer according to the ratio of Example 3 in Table 1, and the oxygen index synergist was obtained after stirring uniformly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com