Ti3C2Tx MXene one-dimensional hollow nanotube as well as preparation method and application thereof

A technology of hollow tubes and fibers, which is applied in the field of preparation of one-dimensional hollow tubes, can solve the problems of cumbersome preparation process and achieve the effects of avoiding aggregation and stacking, low energy consumption, and avoiding long ion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

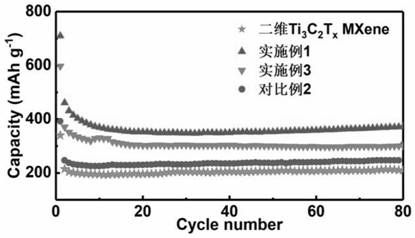

Embodiment 1

[0042] (1) Prepare 0.4 mg / mL Ti 3 C 2 T x The MXene suspension is collected as solution A in a water bath;

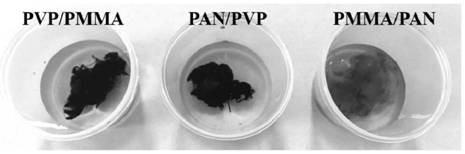

[0043] (2) Add 0.8 g of PMMA and 0.2 g of PVP with an average molecular weight of 1,300,000 to 4.5 mL of DMF, stir under a magnetic stirrer to dissolve completely, and stir for 12 h to obtain solution B;

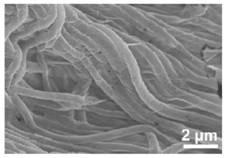

[0044] (3) The solution B was electrospun and collected with solution A under stirring. The positive voltage of electrospinning was 12kV, the negative pressure was -6 kV, the receiving distance was 10 cm, and the spinning temperature was 40°C. Fiber precursor;

[0045] (4) washing the fiber precursor obtained in step (3) three times with deionized water;

[0046] (5) Dry the fiber precursor obtained in step (4) in a freeze dryer for 48 h;

[0047] (6) Put the dried fiber precursor obtained in step (5) in a porcelain boat, and under the protection of a hydrogen-argon mixture atmosphere, raise the temperature to 150°C at a heating rate of 1°C / min, keep it warm for...

Embodiment 2

[0049] (1) Prepare 0.6 mg / mL Ti 3 C 2 T x The MXene suspension is collected as solution A in a water bath;

[0050] (2) Add 0.8 g of PMMA and 0.2 g of PVP with an average molecular weight of 1,300,000 to 4.5 mL of DMF, stir under a magnetic stirrer to dissolve completely, and stir for 12 h to obtain solution B;

[0051] (3) The solution B was electrospun and collected with solution A under stirring. The positive voltage of electrospinning was 12kV, the negative pressure was -6 kV, the receiving distance was 10 cm, and the spinning temperature was 40°C. Fiber precursor;

[0052] (4) washing the fiber precursor obtained in step (3) three times with deionized water;

[0053] (5) Dry the fiber precursor obtained in step (4) in a freeze dryer for 48 h;

[0054] (6) Put the dried fiber precursor obtained in step (5) in a porcelain boat, and under the protection of a hydrogen-argon mixture atmosphere, raise the temperature to 150°C at a heating rate of 1°C / min, keep it warm for...

Embodiment 3

[0056] (1) Prepare 0.8 mg / mL Ti 3 C 2 T x The MXene suspension is collected as solution A in a water bath;

[0057] (2) Add 0.8 g of PMMA and 0.2 g of PVP with an average molecular weight of 1,300,000 to 4.5 mL of DMF, stir under a magnetic stirrer to dissolve completely, and stir for 12 h to obtain solution B;

[0058] (3) The solution B was electrospun and collected with solution A under stirring. The positive voltage of electrospinning was 12kV, the negative pressure was -6 kV, the receiving distance was 10 cm, and the spinning temperature was 40°C. Fiber precursor;

[0059] (4) washing the fiber precursor obtained in step (3) three times with deionized water;

[0060] (5) Dry the fiber precursor obtained in step (4) in a freeze dryer for 48 h;

[0061] (6) Put the dried fiber precursor obtained in step (5) in a porcelain boat, and under the protection of a hydrogen-argon mixture atmosphere, raise the temperature to 150°C at a heating rate of 1°C / min, keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com