FeOOH/Fe3O4/WO3/TiO2 photo-Fenton catalytic membrane as well as preparation method and application thereof

A technology of catalytic membrane and carrier membrane, which is applied in the field of membrane catalysis, can solve the problems of low catalytic efficiency of plasma electrolytic oxidation catalytic membrane and difficult recovery of Fenton-like catalysts, and achieve excellent catalytic efficiency, uniform distribution of active components, and optimal application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A FeOOH / Fe 3 o 4 / WO 3 / TiO 2 The preparation method of photo-Fenton catalytic membrane specifically comprises the following process steps:

[0059] (1) Titanium substrate pretreatment: Use a file, 500-mesh sandpaper, and 1000-mesh sandpaper to polish the pure titanium substrate of brand TA1 in sequence to remove stains and oxide layers on the surface of the substrate to make it smooth, and then use deionized water, anhydrous Ultrasonic cleaning with ethanol for 5 minutes, rinse with absolute ethanol, and dry in warm air;

[0060] (2) Alkaline electrolyte solution: Dissolve 2g of phosphotungstic acid, 6g of potassium ferrocyanide, and 14g of sodium phosphate in deionized water, mix well, and set the volume to 1L to obtain phosphotungstic acid, potassium ferrocyanide, The concentration of sodium phosphate is 2g / L, 6g / L, 14g / L alkaline electrolyte;

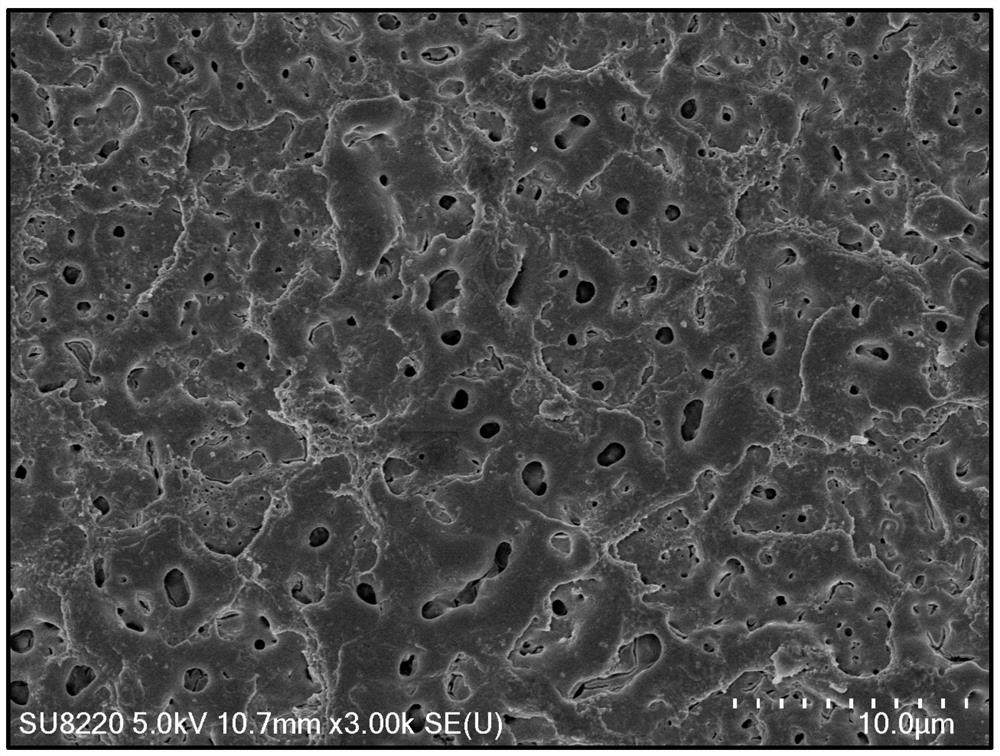

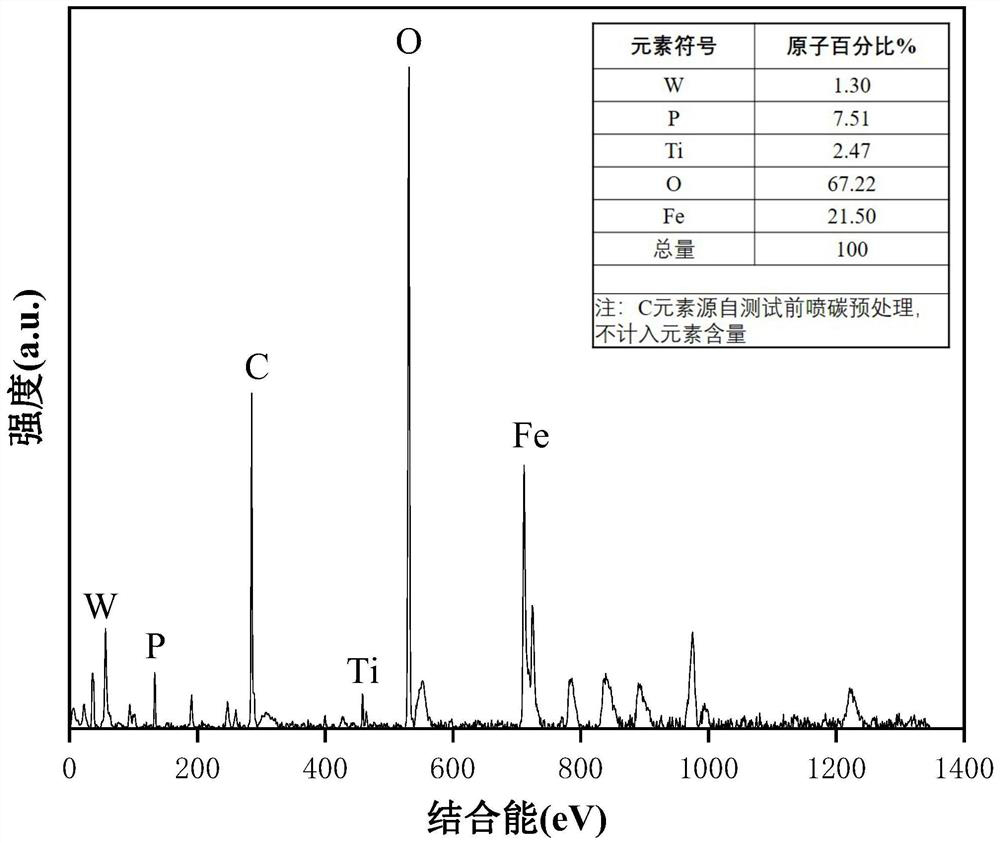

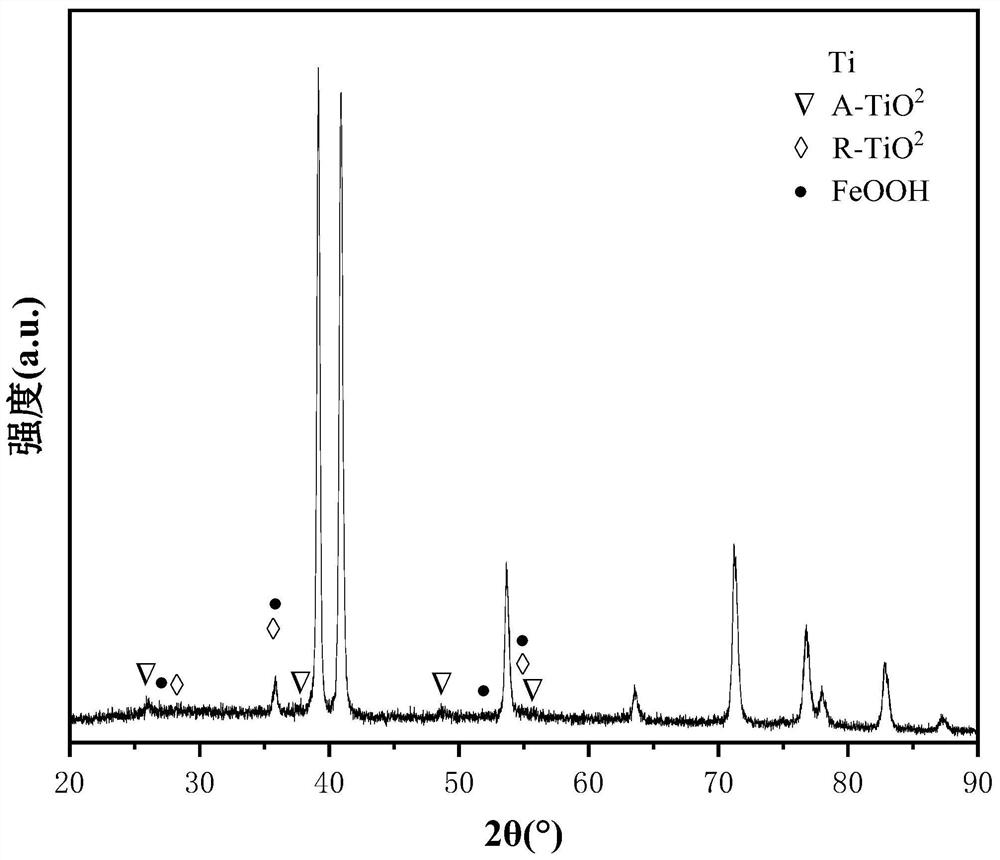

[0061] (3) Preparation of carrier film by plasma electrolytic oxidation: connect the dried substrate in step (1) to th...

Embodiment 2

[0071] A FeOOH / Fe 3 o 4 / WO 3 / TiO 2 The preparation method of photo-Fenton catalytic membrane specifically comprises the following process steps:

[0072] (1) Titanium substrate pretreatment: Use a file, 500-mesh sandpaper, and 1000-mesh sandpaper to polish the pure titanium substrate of brand TA1 in sequence to remove stains and oxide layers on the surface of the substrate to make it smooth, and then use deionized water, anhydrous Ultrasonic cleaning with ethanol for 5 minutes, rinse with absolute ethanol, and dry in warm air;

[0073] (2) Alkaline electrolyte solution: Dissolve 0.5g phosphotungstic acid, 6g potassium ferrocyanide, and 14g sodium phosphate in deionized water, mix well, and set the volume to 1L to obtain phosphotungstic acid and potassium ferrocyanide , The concentration of sodium phosphate is respectively 0.5g / L, 6g / L, 14g / L alkaline electrolyte;

[0074] (3) Preparation of carrier film by plasma electrolytic oxidation: connect the dried substrate in st...

Embodiment 3

[0084] A FeOOH / Fe 3 o 4 / WO 3 / TiO 2 The preparation method of photo-Fenton catalytic membrane specifically comprises the following process steps:

[0085] (1) Titanium substrate pretreatment: Use a file, 500-mesh sandpaper, and 1000-mesh sandpaper to polish the pure titanium substrate of brand TA1 in sequence to remove stains and oxide layers on the surface of the substrate to make it smooth, and then use deionized water, anhydrous Ultrasonic cleaning with ethanol for 5 minutes, rinse with absolute ethanol, and dry in warm air;

[0086] (2) Alkaline electrolyte solution: Dissolve 2g of phosphotungstic acid, 6g of potassium ferrocyanide, and 14g of sodium phosphate in deionized water, mix well, and set the volume to 1L to obtain phosphotungstic acid, potassium ferrocyanide, The concentration of sodium phosphate is 2g / L, 6g / L, 14g / L alkaline electrolyte;

[0087] (3) Preparation of carrier film by plasma electrolytic oxidation: connect the dried substrate in step (1) to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com