Ultraviolet curing adhesive tape for invisible cutting as well as preparation method and application of ultraviolet curing adhesive tape

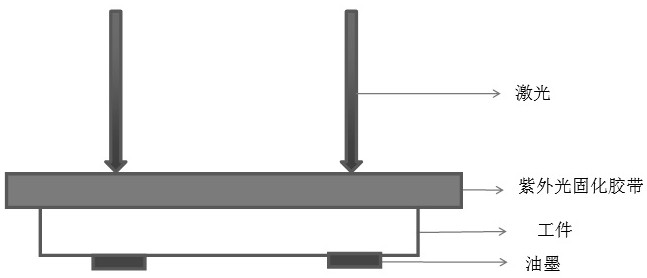

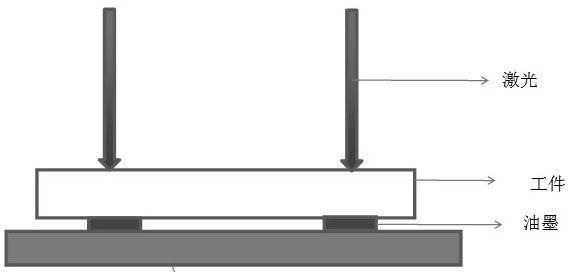

A stealth cutting, ultraviolet light technology, applied in the direction of adhesive, film/sheet release coating, film/sheet release liner, etc., can solve the problems of low light transmission filter, high reflectivity, damage to laser equipment, etc. The effect of high initial adhesion, low adhesion, good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of ultraviolet curing adhesive tape for stealth cutting and its preparation method:

[0032] Substrate layer:

[0033] The substrate is made of PE with a smooth surface and a matte surface with a thickness of 80 μm. Both sides have been treated with corona. The light transmittance of the substrate in the laser band is 89%, the light reflectance is 10%, and the haze is 28%. Dilute the fluororesin with anti-reflection function (the AR110 of Daikin Fluorochemical Co., Ltd. used in the present invention) with a solvent, and then apply it on the smooth surface of the substrate layer with a coating machine according to the dry coating amount of 0.1 μm, and then use The speed of 10m / min is dried through six 3-meter ovens. The temperature of the oven is 40°C, 50°C, 60°C, 60°C, 60°C, and 50°C, and then it is wound up to form a substrate layer to be used. .

[0034] Acrylic pressure sensitive adhesive layer:

[0035] The acrylic resin is SV-8900 from Showa Denko, the fu...

Embodiment 2

[0045] A kind of ultraviolet curing adhesive tape for stealth cutting and its preparation method:

[0046] Substrate layer:

[0047] The substrate is made of PO with a smooth surface and a matte surface with a thickness of 80 μm. The two sides have been treated with corona. The light transmittance of the substrate in the laser band is 84%, the light reflectance is 13%, and the haze is 32%. The fluororesin with anti-reflection function (the AR110 of Daikin Fluorochemical Industry used in the present invention) is diluted with a solvent, and then coated on the smooth surface of the substrate layer with a coating machine according to the dry coating amount of 0.5 μm, and then The speed of 10m / min is dried through six 3-meter ovens. The temperature of the oven is 40°C, 50°C, 60°C, 60°C, 60°C, and 50°C, and then it is wound up to form a substrate layer to be used. .

[0048] Acrylic pressure sensitive adhesive layer:

[0049] The acrylic resin is LKG1715 from Fujikura Chemical C...

Embodiment 3

[0059] A kind of ultraviolet curing adhesive tape for stealth cutting and its preparation method:

[0060] Substrate layer:

[0061] The substrate is made of PET with a thickness of 100 μm on both sides of the smooth surface, and its two sides have been treated with corona. The light transmittance of the substrate in the laser band is 89%, the light reflectance is 9%, and the haze is 6%. Dilute the fluororesin with anti-reflection function (the AR110 of Daikin Fluorochemical Co., Ltd. used in the present invention) with a solvent, and then apply it on the smooth surface of the substrate layer with a coating machine according to the dry coating amount of 1 μm, and then apply it on the smooth surface of the substrate layer with a 10m The speed of / min is dried through 6 ovens with 3 meters in length. The temperature of the oven is 40°C, 50°C, 60°C, 60°C, 60°C, and 50°C, and then it is wound up to form a ready-to-use substrate layer.

[0062] Acrylic pressure sensitive adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com