Wear-resistant and corrosion-resistant ternary boride/stainless steel composite material and manufacturing method thereof

A technology of ternary boride and composite materials, which is applied in the field of wear-resistant and corrosion-resistant ternary boride/stainless steel composite materials and its preparation, to achieve the effects of promotion and innovation, a wide range of options, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

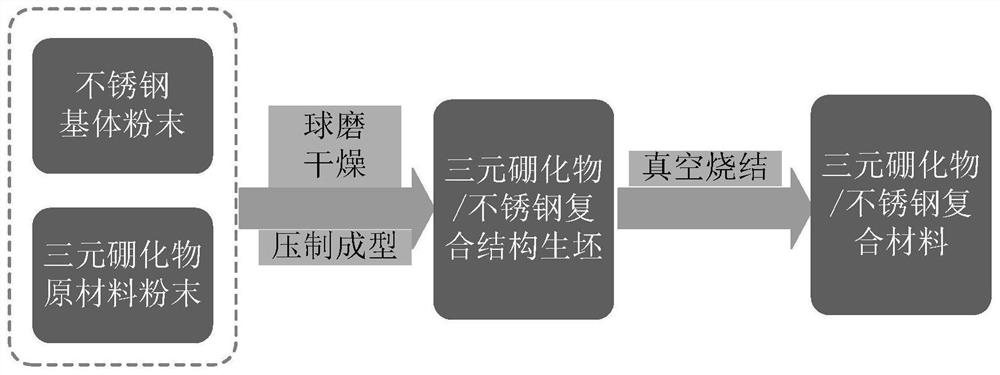

[0039] The invention provides a technical solution: a method for preparing a wear-resistant and corrosion-resistant ternary boride / stainless steel composite material, which specifically includes the following steps: A. 1Cr13 martensitic stainless steel alloy powder prepared by gas atomization is selected as the steel substrate Powder, with an average particle size of 14.8 μm, and its main chemical element percentages are: C: 0.12, Cr: 12, Mn: 0.8, Si: 0.6, Ni: 0.5 and Fe: the balance.

[0040]The average particle size of the ternary boride raw material alloy powder is 21.5 μm, and the percentages of its main chemical elements are: 5-15wt% FeB powder, 5-15wt% Cr powder, 10-20wt% Mo powder, 6-8wt% Ni powder, 0.5~2wt% Cu powder, 1~3wt% NbC powder, 0.5~1.2wt% La 2 o 3 powder and Fe powder balance.

[0041] B. Mixing materials: liquid paraffin is selected as the molding agent, the mass ratio of the stainless steel matrix powder and the molding agent is 48:2, and the mixing time i...

Embodiment 2

[0047] The difference from Example 1 is that the present invention provides a technical solution: a method for preparing a wear-resistant and corrosion-resistant ternary boride / stainless steel composite material, which specifically includes the following steps:

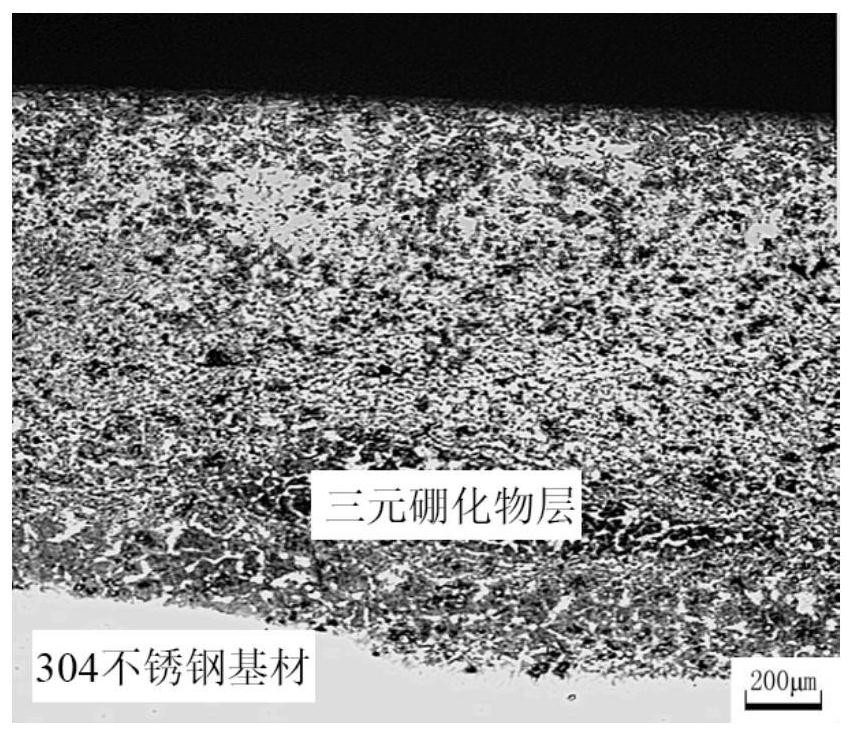

[0048] A. The 304 austenitic stainless steel alloy powder prepared by plasma atomization is used as steel substrate powder, with an average particle size of 12.8 μm, and the percentages of its main chemical elements are: C:0.08, Cr:19.5, Mn:1.9, Si:0.8, Ni : 8.5 and Fe: margin.

[0049] The average particle size of the ternary boride raw material alloy powder is 18.7 μm, and its main chemical element percentage is 10-20wt% FeB powder, 10-20wt% Cr powder, 15-30wt% Mo powder, 7-10wt% Ni powder, 1.5-3.0 wt% Cu powder, 2~5wt% VC powder, 1.0~2.0wt% Y 2 o 3 powder and Fe powder balance.

[0050] B. Mixing materials: polyvinyl butyral anhydrous ethanol solution is selected as the molding agent, the mass ratio of stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com