Bactericidal composition containing isotianil and iprobenfos

A technology of isothiazide and isothiazide, applied in the field of pesticides, can solve the problems of reducing the efficacy of fungicides, high loss rate, pesticide pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment is a sustained-release agent, and the preparation process of the sustained-release agent is as follows:

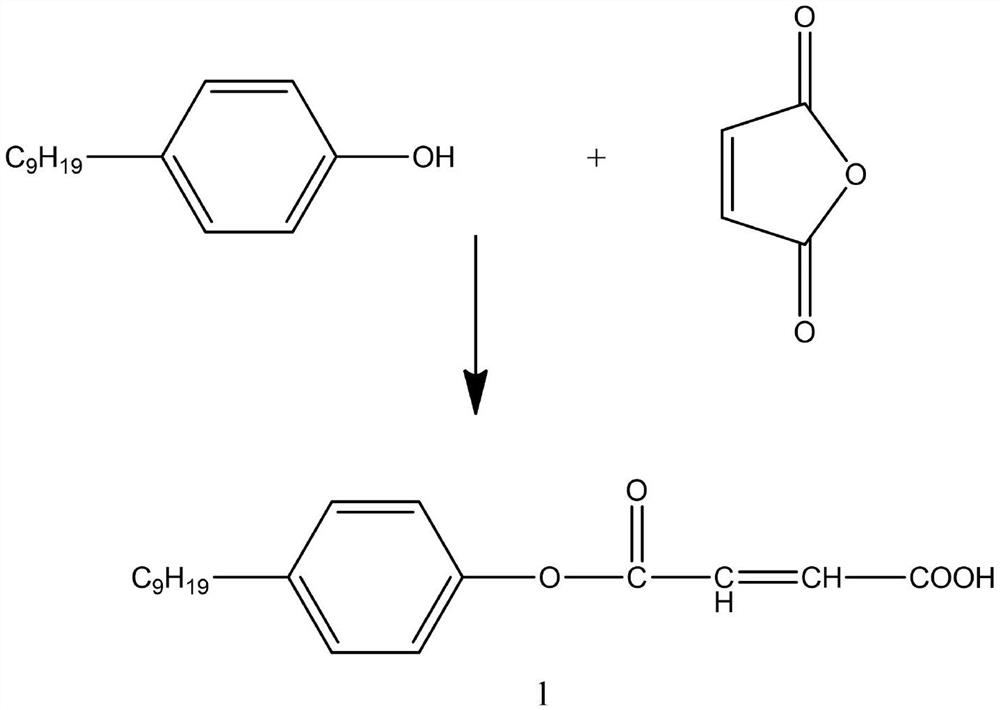

[0034] S1: Add maleic anhydride to a three-necked flask equipped with a nitrogen conduit, a reflux condenser, and a stirrer, place the three-necked flask in a constant temperature oil bath, and heat while stirring at a stirring speed of 100r / min. Control the heating rate at 2°C / min, raise the temperature to 60°C and continue to stir until the maleic anhydride is completely melted, add the catalyst and nonylphenol, then raise the temperature to 82°C and reflux for 4 hours, cool to room temperature after the reaction, Intermediate 1 is obtained; the molar ratio of maleic anhydride and nonylphenol is controlled to be 1:1.00, the catalyst is anhydrous sodium acetate, and the amount of catalyst is 0.1% of the total weight of maleic anhydride and nonylphenol;

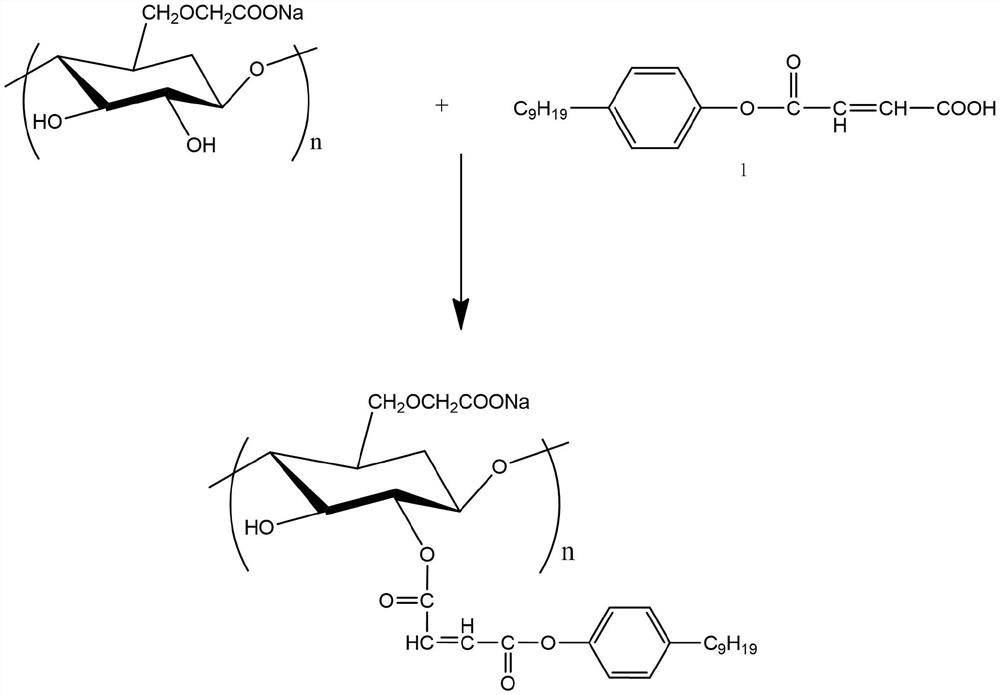

[0035] S2: Add sodium hydroxymethyl cellulose to aqueous acetic acid solution, stir and s...

Embodiment 2

[0040] The present embodiment is a sustained-release agent, and the preparation process of the sustained-release agent is as follows:

[0041] S1: Add maleic anhydride to a three-necked flask equipped with a nitrogen conduit, a reflux condenser, and a stirrer. The three-necked flask is placed in a constant temperature oil bath and heated while stirring at a stirring speed of 200r / min. Control the heating rate to 4°C / min, heat up to 60°C and continue to stir until the maleic anhydride is completely melted, add the catalyst and nonylphenol, then raise the temperature to 85°C and reflux for 4.5 hours, cool to room temperature after the reaction , obtain intermediate 1; control the mol ratio of maleic anhydride and nonylphenol to be 1:1.03, the catalyst is anhydrous sodium acetate, and the consumption of catalyst is 0.2% of the total weight of maleic anhydride and nonylphenol;

[0042] S2: Add hydroxymethyl cellulose sodium to the aqueous acetic acid solution, stir and swell for 3...

Embodiment 3

[0047] The present embodiment is a sustained-release agent, and the preparation process of the sustained-release agent is as follows:

[0048] S1: Add maleic anhydride to a three-necked flask equipped with a nitrogen conduit, a reflux condenser, and a stirrer, place the three-necked flask in a constant temperature oil bath, and heat while stirring at a stirring speed of 300r / min. Control the heating rate at 5°C / min, heat up to 60°C and continue to stir until the maleic anhydride is completely melted, add the catalyst and nonylphenol, then raise the temperature to 88°C and reflux for 5 hours, cool to room temperature after the reaction, Intermediate 1 is obtained; the molar ratio of maleic anhydride and nonylphenol is controlled to be 1:1.05, the catalyst is anhydrous sodium acetate, and the amount of catalyst is 0.3% of the total weight of maleic anhydride and nonylphenol;

[0049] S2: Add sodium hydroxymethyl cellulose to aqueous acetic acid solution, stir and swell for 4 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com