Curry sauce and preparation method thereof

A curry sauce and audio technology, applied in the fields of food shearing, food science, etc., can solve the problems of low aroma, long heating time, rough taste, etc., and achieve the effect of activating liver cells, inhibiting cancer cells, and having a delicate taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

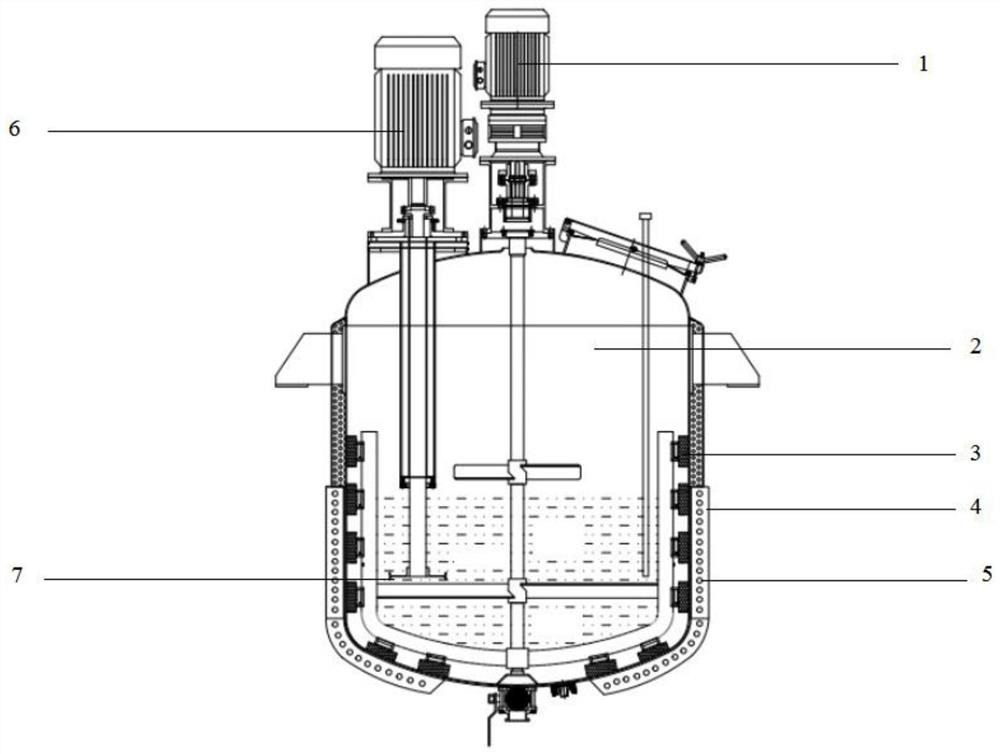

Image

Examples

preparation example Construction

[0018] The present invention provides a method of preparing curry sauce comprising the step of: heating the fuel audio to the set temperature, adding fragrant material to stir fry, and the high-speed shear system is dispersed by high-speed shear system, and finally add sugar, starch And taste, stir fry under the above-mentioned frying conditions.

[0019] In the present invention, the oil is preferably comprised of 180-190 parts of the weight of the weight: 1-3 parts of the butter 145-155 parts and cumin oil, more preferably, according to the weight of the parts. The following raw materials: 187 gougoes, 150 butter and 2 cumin oils. The present invention is not particularly limited for the source of hg, butter and cumin oil, and can be used in the art.

[0020] In the present invention, the incense is preferably included in the weight of the weight of the weight: 35-45 ginger powder, 18-2 fennel powder, 0.5-1.5 parts of licorice powder, 4-6 lilac powder, cardamom powder 4-6 copies...

Embodiment 1

[0032]Accurately weigh 187kg, butter 150kg, cumin 2kg is placed in audio heating cork, start high-frequency generator, set audio 15000 Hz, make audio heating cankure to heat, 10-15min fried When the oil temperature rises to 145 ° C, the turmeric powder 40kg, fennel powder 20kg, licorice powder 1kg, clove powder 5kg, cardamom powder 5kg, pepper 5kg, cinnama powder 60kg, cinnamon 3kg, Wanzi powder 1kg, mustard powder 3kg was placed in an audio heating cider, turned on the mixer and high speed shear dispersing machine (2900 rpm) to carry out a high temperature for sputum. The white sugar 100kg, 330kg of starch was placed in an audio heating cider, and the above stirring and high speed shear scattered step were continued, and the curry sauce was obtained by stirring 20 minutes.

Embodiment 2

[0034] Accurately weigh 180kg, butter 145kg, 然 油 1kg is placed in audio heating cooking tank, start high frequency generator, set audio to 14000 Hz, make the audio heating cider start heating, 10-15min frulating pot When the oil temperature rises to 130 ° C, the turmeric powder 35kg, anise powder 18kg, glycycetic powder 0.5kg, clove powder 4kg, 4kg of cardamom powder 4kg, 4kg, cinnamon powder, 0.5kg, Guanzi powder 0.5kg, Mustard Powder 2kg is placed in an audio heating cider, open the mixer and the high-speed shear disperser (2500 rpm) for fragrant high temperature speculation for 35 min. The white sugar was 95kg, starch 320kg, and MSG 90KG was placed in an audio heating cider, and the above agitation and high speed shear scattered step were continued, and the curry sauce was obtained for 15 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com