Polymorphic zeolite/C-S-H composite adsorption material as well as preparation method and application thereof

A composite adsorption material, C-S-H technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as unsatisfactory removal performance, high cost, heavy metal adsorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

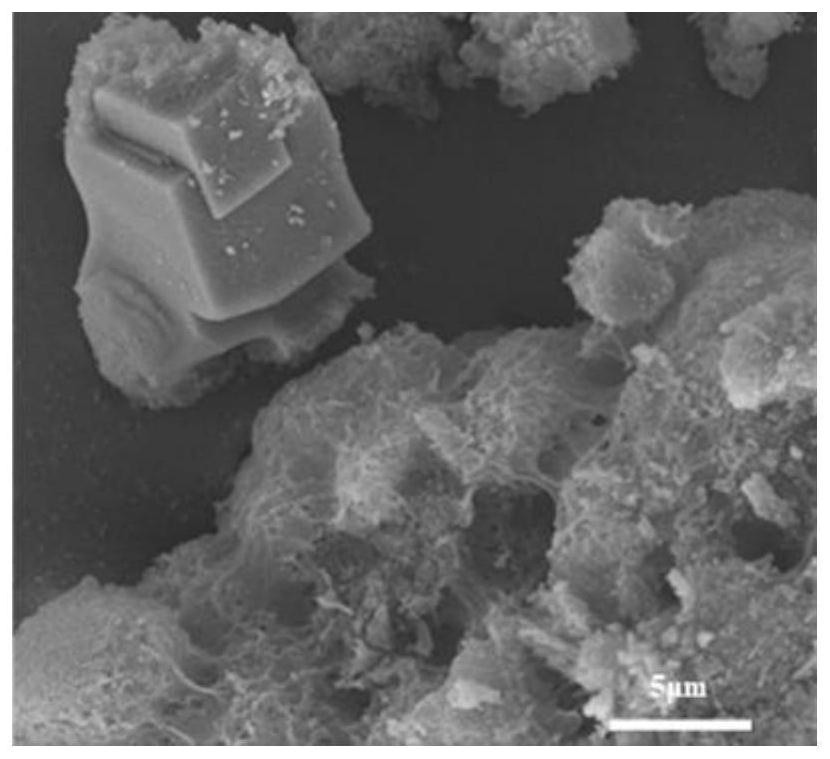

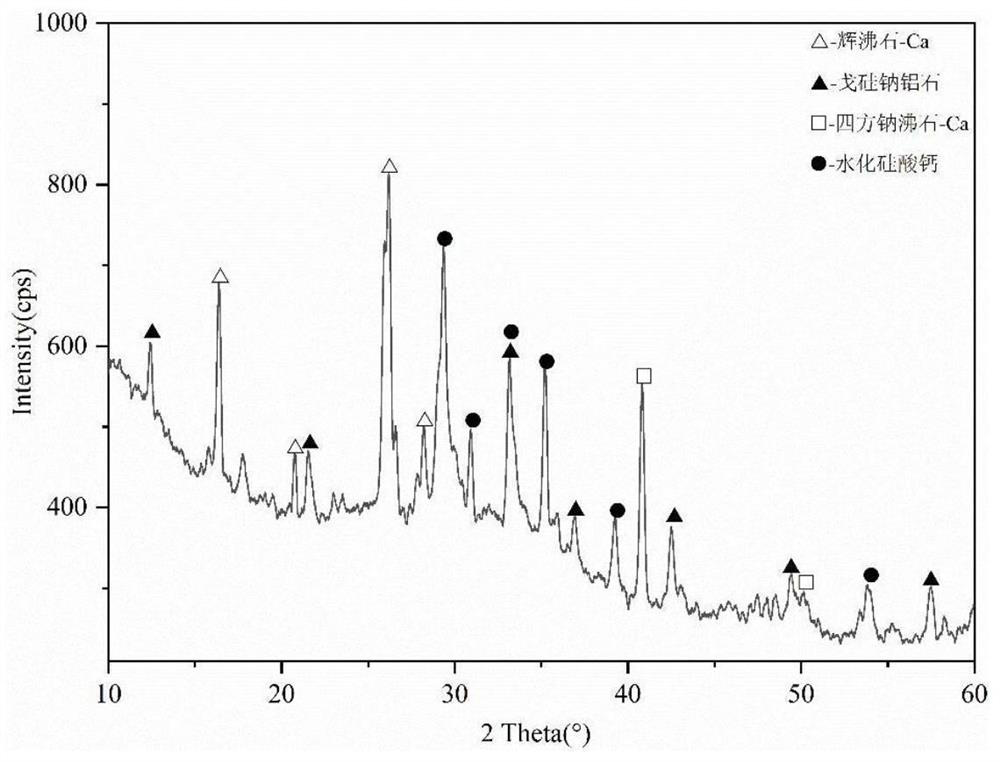

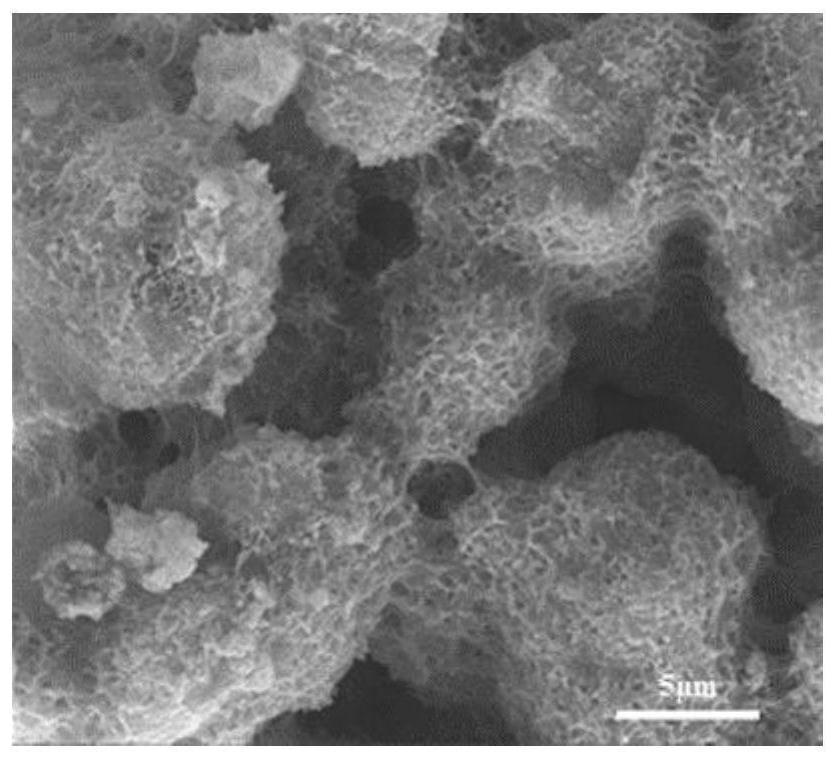

[0054] Calcium oxide and aluminum-silicon raw materials (mass ratios of calcium / silicon are 0.38, 0.45, 0.75, 0.80 respectively; Si / Al mass ratio is 1.7) are placed in a sodium hydroxide solution with a concentration of 0.5mol / L to obtain a slurry, wherein, The liquid-solid ratio is 15ml / g, and it is heated to 170°C in a closed container for hydrothermal reaction for 3 hours; followed by solid-liquid separation and drying to obtain the composite material.

[0055] The separated composite material was subjected to the heavy metal adsorption experiment, and the realization process was as follows: prepare a heavy metal ion solution with a concentration of 100mg / L with the nitrate of the corresponding metal to be tested, adjust the pH of the heavy metal ion solution to 4.5, and then mix the composite adsorbent according to 0.1 The dosage of g / L is added to the heavy metal ion solution, shaken in a constant temperature oscillator for 4 hours, and then taken out. The conditions of t...

Embodiment 2

[0060] Compared with Case No. 3 of Example 1, the only difference is that the water heating temperatures are 130°C, 150°C, 190°C, and 210°C respectively

[0061] The adsorption effect is shown in Table 2:

[0062]

[0063] 3* is the No. 3 case of embodiment 1;

Embodiment 3

[0065] Compared with Case No. 3 of Example 1, the only difference is that the hydrothermal reaction time is respectively 0.5h, 1h, 5h, and 7h;

[0066] table 3:

[0067]

[0068]

[0069] 3* is the No. 3 case of embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com