A method for brazing dissimilar materials assisted by three-dimensional negative expansion network composite interlayer material

A technology of network compounding and dissimilar materials, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as large differences in thermal expansion coefficients, large residual stress in joints, enhanced phase agglomeration content, etc., to achieve reduction Thermal expansion coefficient, relief of residual stress, good effect of joint structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific Embodiment 1: In this embodiment, a method for assisting brazing of dissimilar materials by a three-dimensional negative expansion network composite intermediate layer material is carried out according to the following steps:

[0026] 1. Preparation of three-dimensional negative expansion network composite interlayer material precursor:

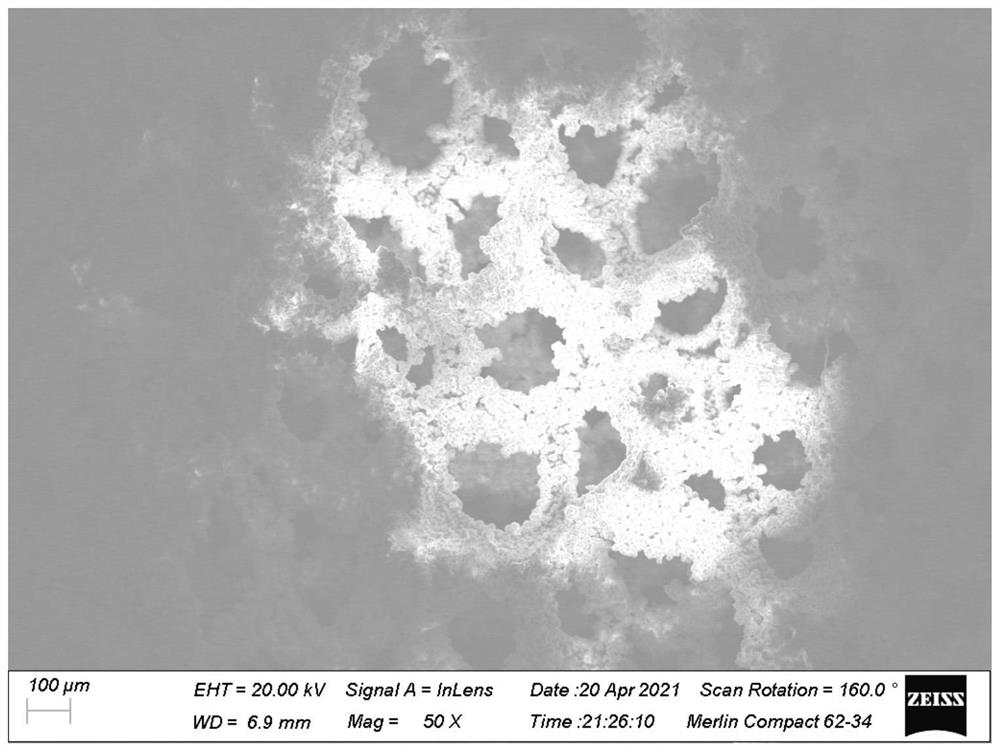

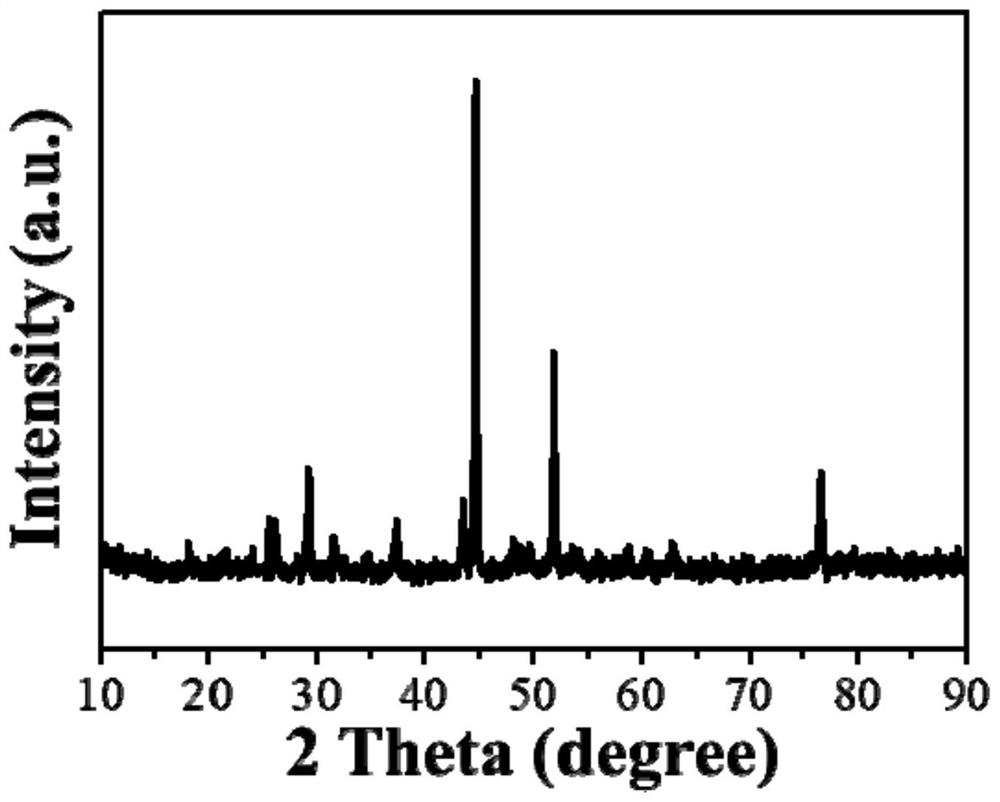

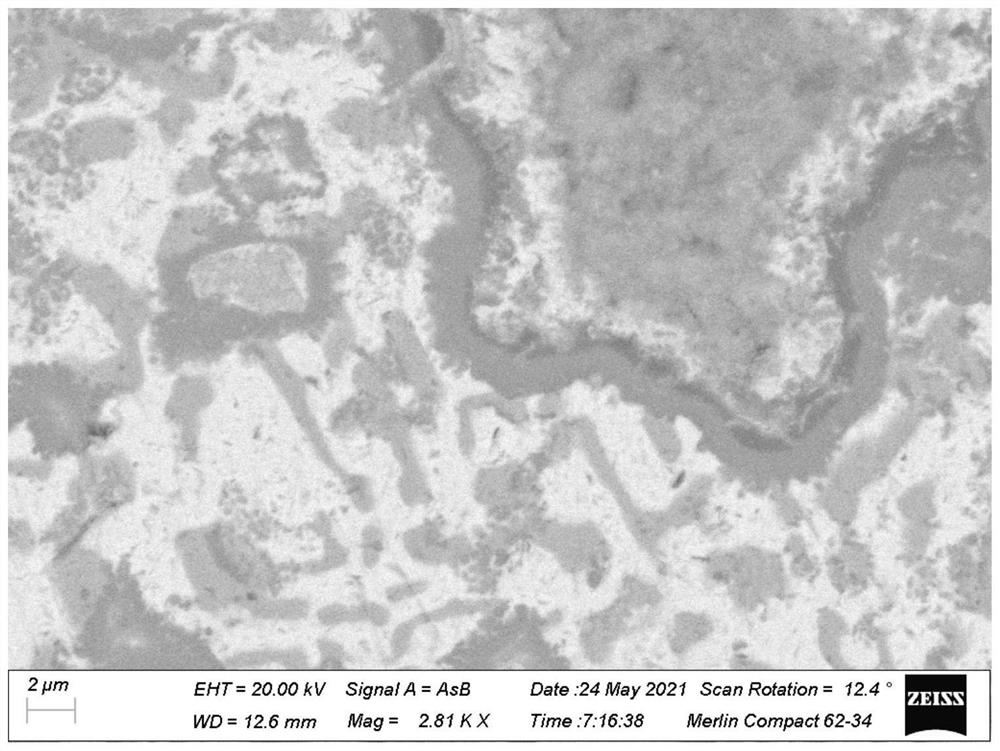

[0027] Under the condition of ultrasonic water bath, add cationic metal salt and anionic metal salt to deionized water, stir until they are uniformly dispersed to obtain a mixed solution, put the mixed solution in a reaction kettle, and then impregnate the foam metal in the mixed solution, at a temperature of Under the condition of 100 ℃ ~ 180 ℃, hydrothermal reaction for 2h ~ 12h, and then naturally cooled to room temperature to obtain the precursor, the precursor was washed and dried to obtain the precursor of the three-dimensional negative expansion network composite intermediate layer material;

[0028] The anion metal sal...

specific Embodiment approach 2

[0044] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the precursor is washed and dried according to the following steps: the precursor is alternately washed three times with deionized water and absolute ethanol, and then Dry for 3 hours to 24 hours at a temperature of 60°C to 120°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the cationic metal salt in step 1 is scandium nitrate, scandium chloride, yttrium nitrate or yttrium chloride. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com