Super-oleophylic water purification composite adsorbent and preparation method thereof

A composite adsorption and super-oleophilic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problem that the oil content in the effluent cannot meet the discharge requirements, the adverse effects of pipeline urban sewage treatment plants, Aquatic death and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

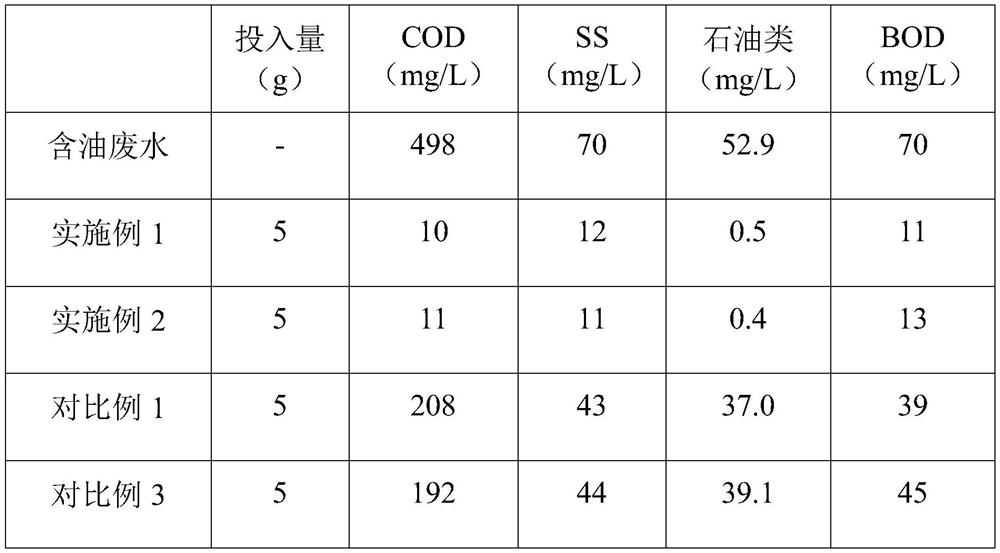

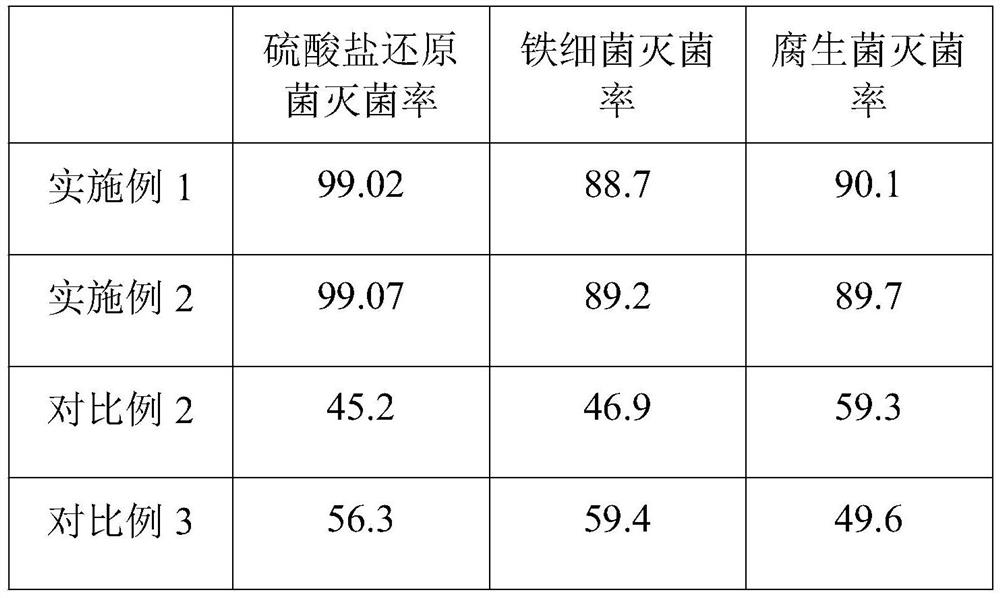

Examples

Embodiment 1

[0028] A super-lipophilic water-purifying composite adsorbent, in parts by weight, mainly includes:

[0029] 10 parts of low rank coal, 10 parts of sodium hypochlorite, 10 parts of copper nitrate, 60 parts of alkali vapor.

[0030] A kind of preparation of super lipophilic water purification composite adsorbent, the preparation method of described super lipophilic water purification composite adsorbent is:

[0031] (1) Perform the first thermal decomposition of low-rank coal at 400°C. After most of the gas and tar are precipitated, raise the temperature to 500°C and continue the thermal decomposition. After the residue is completely solidified, stop heating and cool naturally to room temperature , to make semi-coke;

[0032] (2) Grind the semi-coke prepared in step (1), pass through 400 mesh sieve and 200 mesh sieve successively, select 200-400 mesh semi-coke powder; prepare a sodium hypochlorite solution with a mass number of 10%, and sieve it immediately The semi-coke is s...

Embodiment 2

[0037] A super-lipophilic water-purifying composite adsorbent, in parts by weight, mainly includes:

[0038] 20 parts of low rank coal, 30 parts of sodium hypochlorite, 30 parts of copper nitrate, 120 parts of alkali vapor.

[0039] A kind of preparation of super lipophilic water purification composite adsorbent, the preparation method of described super lipophilic water purification composite adsorbent is:

[0040] (1) Perform the first thermal decomposition of low-rank coal at 500°C. After most of the gas and tar are precipitated, raise the temperature to 550°C and continue the thermal decomposition. After the residue is completely solidified, stop heating and cool naturally to room temperature , to make semi-coke;

[0041] (2) Grind the semi-coke prepared in step (1), pass through a 400-mesh sieve and a 200-mesh sieve successively, select 200-400 mesh semi-coke powder; configure a mass number of 10% sodium hypochlorite solution, immediately sieve The semi-coke is soaked i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com