Equipment for preparing metal test piece and structural piece by using high-energy beam

A high-energy beam and test piece technology, which is applied in the preparation of test samples, additive manufacturing, additive processing, etc., can solve the problems of poor formability, high manufacturing cost, and inability to take advantage of high-performance metal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

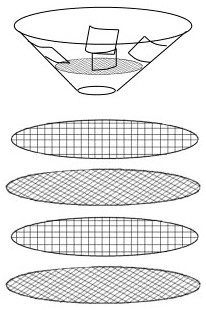

[0063] Figure 7 Shown are multiple aluminum alloy button-shaped specimens fabricated from the front side of a cooled copper plate using this equipment in high-throughput forming mode. It can be seen that there is a button-shaped sample prepared by laser in each powder loading tank. The added powder composition and processing parameters were changed in the experiment, and a large number of samples with different contents of added ingredients and different laser irradiation power and processing time were obtained. , after metallographic observation, we get Figure 8 As shown in the metallographic structure, it can be seen that after laser processing and water cooling, a relatively dense structure is obtained.

Embodiment 2

[0065] Figure 9Shown is a plurality of columnar high-entropy alloys obtained by cooling the back of the copper plate under the specific structure forming mode of this equipment. In this experiment, the powder feeding rate and processing parameters of different powders were changed. After cutting it from the substrate, several approx. 23cm columnar sample, Figure 10 The metallographic structure is also shown in Fig. 1, and it can be seen that the continuous growth of columnar crystals is generated due to the high thermal gradient caused by laser and water cooling.

Embodiment 3

[0067] Figure 11 Shown is a plurality of columnar nickel-based superalloys obtained by cooling the back of the copper plate under the specific structural forming mode of this equipment. In this experiment, the powder feeding rate, processing parameters and sample growth height of different powders were changed. After cutting it from the substrate , obtained a number of columnar samples ranging from 30cm to 80cm, from Figure 12 From the metallographic structure, it can be seen that the high temperature gradient has obtained continuous directional growth of columnar crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com