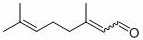

Method for preparing citral through dehydrolinalool rearrangement reaction

A technology for dehydrolinalool and rearrangement reactions, applied in catalytic reactions, preparation of carbon-based compounds, chemical instruments and methods, etc., to achieve high reactivity and selectivity, convenient source, good economic benefits and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

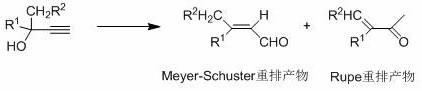

Problems solved by technology

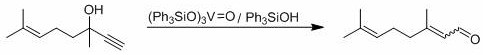

Method used

Image

Examples

Embodiment 1

[0035] 0.152g (1mmol) dehydrolinalool, 3.26mg (0.01mmol) MoO 2 (acac) 2 , 55.6mg (0.2mmol) Ph 3 Add PO, 35.6mg (0.2mmol) 4-tert-butylbenzoic acid and 4mL solvent toluene into a thick-walled pressure-resistant reaction bottle, and put it into a 120 o After reacting 7h in C oil bath, monitor reaction by thin-layer chromatography completely, by 1 H-NMR internal standard method was used to measure the yield of the target product, and the yield of the target product citral was measured to be 53%.

Embodiment 2

[0037] With 0.152g (1mmol) dehydrolinalool, 4.89mg (0.015mmol) MoO 2 (acac) 2 , 55.6mg (0.2mmol) Ph 3 Add PO, 35.6mg (0.2mmol) 4-tert-butylbenzoic acid and 4mL solvent toluene into a thick-walled pressure-resistant reaction bottle, and put it into a 120 o After reacting 7h in C oil bath, monitor reaction by thin-layer chromatography completely, by 1 H-NMR internal standard method was used to determine the yield of the target product, and the yield of the target product citral was measured to be 67%.

Embodiment 3

[0039] With 0.152g (1mmol) dehydrolinalool, 9.78mg (0.03mmol) MoO 2 (acac) 2 , 55.6mg (0.2mmol) Ph 3 Add PO, 35.6mg (0.2mmol) 4-tert-butylbenzoic acid and 4mL solvent toluene into a thick-walled pressure-resistant reaction bottle, and put it into a 120 o After reacting 7h in C oil bath, monitor reaction by thin-layer chromatography completely, by 1 H-NMR internal standard method was used to determine the yield of the target product, and the yield of the target product citral was 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com