Production method of diamido-arene

A technology for diamino aromatic hydrocarbons and production methods, which is applied in the formation/introduction of amino groups, the preparation of amino compounds, chemical instruments and methods, etc. and high selectivity, beneficial to recycling, and the effect of expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

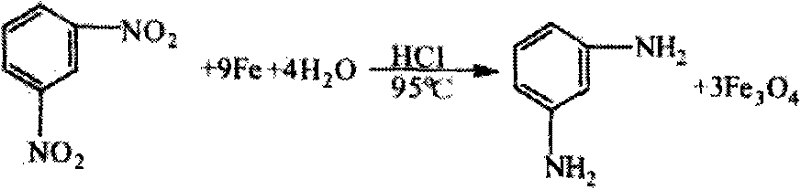

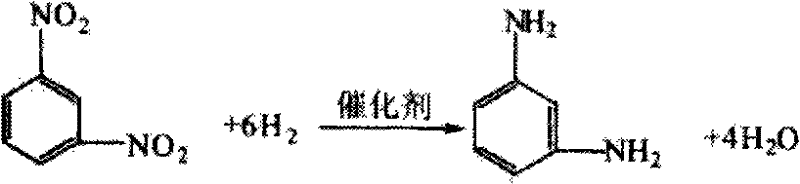

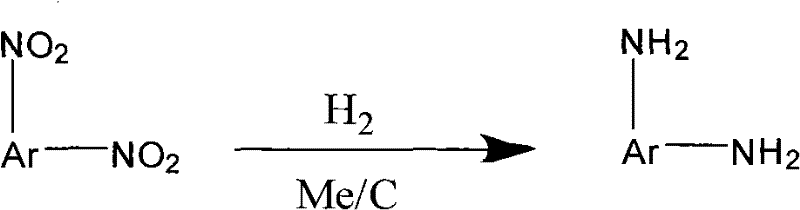

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.05g of palladium chloride and dissolve it in deionized water containing hydrochloric acid, and impregnate 3.0g of mesoporous carbon in equal volume (the pore volume of mesoporous carbon is 0.9mL / g, and the specific surface area is 700m 2 / g, pore diameter is 5nm), impregnated for 10h, and then dried at 120°C to obtain the catalyst precursor.

[0027] 0.3g of the catalyst precursor was placed in the constant temperature zone of the reactor, and both ends were supported by quartz sand. Restore with hydrogen at 250°C for 3 hours, lower the reaction temperature to 60°C, increase the hydrogen pressure to 3.0MPa, add methanol simulation raw material containing 20% m-dinitrobenzene to carry out hydrogenation reaction, the mass space velocity of m-dinitrobenzene It is 2.5 kg / (kg catalyst) / hour. After about 5 hours of stabilization, a sample was collected every 15 minutes for compositional analysis by gas chromatography. The number of samples collected is not less th...

Embodiment 2

[0029] 0.05 g of palladium chloride in Example 1 was replaced with 0.06 g of ruthenium chloride, the composition is shown in Table 1, and other steps were the same as in Example 1.

Embodiment 3

[0031] Replace 0.05g palladium chloride in the embodiment 1 with the silver nitrate of 0.047g, see table 1 for composition, other steps are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com