Alkylene oxide-tetrahydrofuran copolymer and preparation method thereof

A technology of tetrahydrofuran and alkylene oxide, applied in the field of alkylene oxide-tetrahydrofuran copolymer and preparation, can solve the problems of poor reaction activity and selectivity, difficult separation, and high preparation of finished products, so as to improve the reaction activity and selectivity, and the content of by-products. The effect of reducing and reducing the cost of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

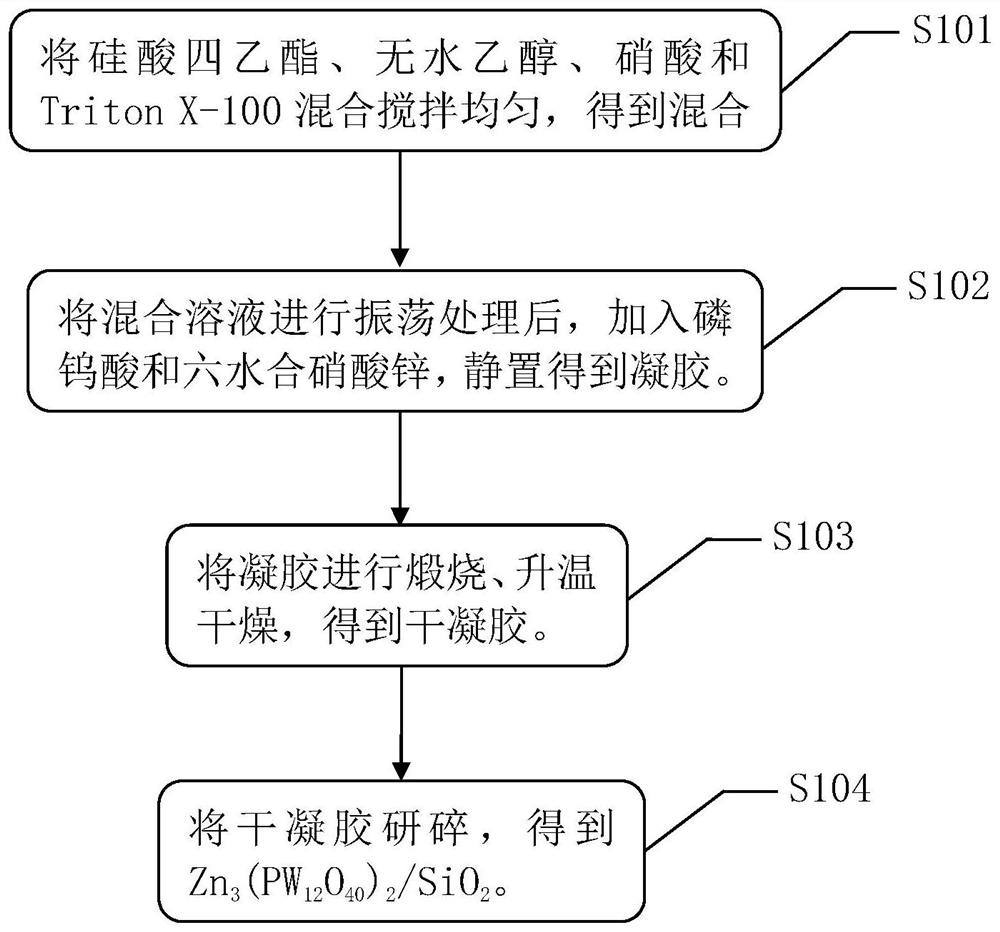

preparation example Construction

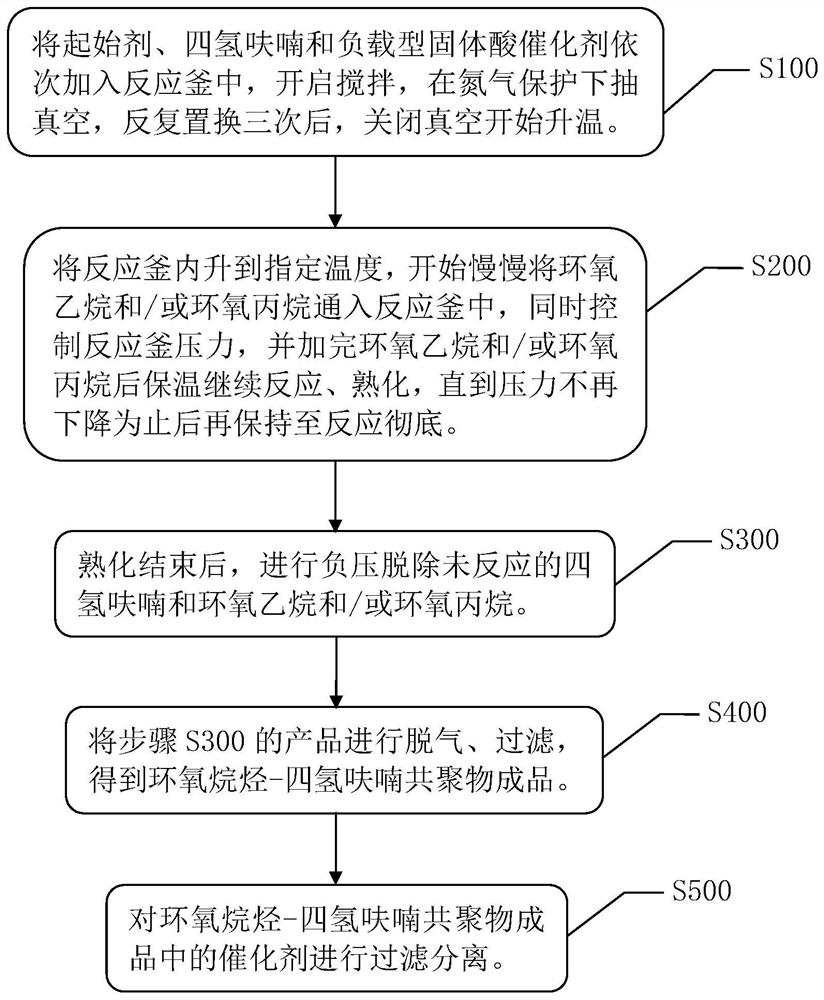

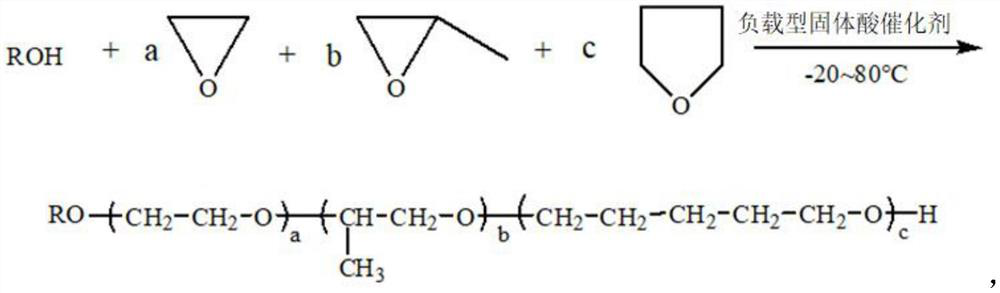

[0037] Such as figure 1 Shown in, the present invention also provides a kind of preparation method of alkylene oxide-THF copolymer, comprises the following steps:

[0038] Step S100. Feeding and nitrogen replacement: add the starter, tetrahydrofuran and supported solid acid catalyst into the reaction kettle in sequence, start stirring, vacuumize under the protection of nitrogen, and replace repeatedly (preferably three times), then turn off the vacuum and start heat up;

[0039] Step S200. Reaction: Raise the temperature in the reactor to a specified temperature, start to slowly feed ethylene oxide and / or propylene oxide into the reactor while controlling the pressure of the reactor (preferably controlling the pressure of the reactor within 0.4MPa ), and after adding ethylene oxide and / or propylene oxide, keep warm and continue to react and mature until the pressure no longer drops and then keep until the reaction is complete (generally, the holding time is about 30min); the ...

Embodiment 1

[0055] A kind of alkylene oxide-tetrahydrofuran copolymer of embodiment 1, take load-type solid acid catalyst as catalyzer (hereinafter referred to as Cat.), take ethylene glycol as starter, material tetrahydrofuran, oxyethane, load-type solid The molar ratio of the acid catalyst is 1000:1000:1 (ie THF:EO:Cat.=1000:1000:1), the reaction temperature is -20°C, and the reaction time is 25h. The yield was 52%. By adopting Waters-APC gel permeation chromatography (polystyrene is standard sample, THF is solvent, 40 ℃, flow velocity 0.8mL / min,) detects the molecular weight and molecular weight distribution of this alkylene oxide-tetrahydrofuran copolymer, the result For: the molecular weight is 8000, and the molecular weight distribution index is 1.3.

Embodiment 2

[0057] A kind of alkylene oxide-tetrahydrofuran copolymer of embodiment 2, take load-type solid acid catalyst as catalyzer, take 1,4-butanediol as starter, material tetrahydrofuran, ethylene oxide, load-type solid acid catalyst The molar ratio is 4000:2000:3 (ie THF:EO:CAT.=4000:2000:3), the reaction temperature is 30°C, the reaction time is 9h, and the yield is 68%. By adopting Waters-APC gel permeation chromatography (polystyrene is standard sample, THF is solvent, 40 ℃, flow velocity 0.8mL / min,) detects the molecular weight and molecular weight distribution of this alkylene oxide-tetrahydrofuran copolymer, the result It is: the molecular weight is 12000, and the molecular weight distribution index is 1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com