Method for separating and purifying bacitracin by using thermo-responsive copolymer NPE-108

A separation, purification, and heat-responsive technology, applied in the field of two-phase extraction and downstream separation, can solve the problems of long phase formation time, high cost of polymer synthesis, failure of industrialization, etc., and achieve easy scale, simple operation, Effect of reducing separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

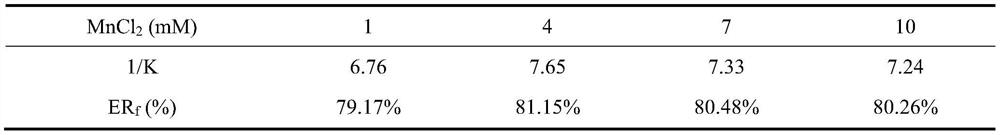

[0021] Example 1 NPE-108 / water recyclable two-phase system for forward extraction of bacitracin

[0022] Add 7mL NPE-108 to a 50mL graduated centrifuge tube, then add 28mL bacitracin fermentation broth, mix well, add MnCl 2 (the concentration in the system is 4mmol / L), shake evenly, adjust the pH of the system to 8.5, place the centrifuge tube in a constant temperature water bath at 30°C and let it stand until two phases with a clear interface are observed, take it out and centrifuge , take out 100 μL from the upper and lower phases with a pipette gun, dilute 10 times with ultrapure water, filter through a 0.45 μm water filter membrane, and measure the concentration of bacitracin in the upper and lower phases in the system by HPLC. The ratio of the concentrations of bacitracin in the upper and lower phases is the distribution coefficient K, and under this extraction condition, the distribution coefficient of bacitracin is 0.12.

Embodiment 2

[0023] Example 2 Back extraction experiment of bacitracin in NPE-108 / water recyclable two-phase system

[0024] Take out the upper phase (fermentation broth enriched phase) in Example 1, add water to the graduated centrifuge tube for the first reverse extraction, the volume of water is 1 / 2 of the volume of NPE-108 initially added, mix and oscillate evenly Finally, adjust the pH of the system to 5.5, place it in a constant temperature water bath at 60 °C and let it stand until two phases with a clear interface are observed, take them out and centrifuge, take out 100 μL from the upper and lower phases with a pipette gun, and wash with ultrapure water Dilute 10 times, filter through a 0.45 μm water filter, and measure the concentration of bacitracin in the upper and lower phases of the system by HPLC.

[0025] The upper phase after the back extraction is taken out, and water is added to the centrifuge tube for the second back extraction. The conditions of the back extraction are ...

Embodiment 3

[0026] The preparation experiment of embodiment 3 methylene disalicylic acid bacitracin

[0027] Methylenedisalicylic acid is dissolved with NaOH and its pH is adjusted to 8.5, and the upper phase and methylenesalicylic acid solution after two back extractions in Example 2 are mixed to adjust the pH of the mixed solution to 4.5, namely Precipitation of bacitracin methylenedisalicylate can be observed. After centrifugation, the supernatant is removed, and the precipitate is placed in a freeze-drying oven (5 hours) to freeze-dry to obtain bacitracin methylenedisalicylate powder. Weigh 6 mg of bacitracin powder, dissolve it in 1 mL of NaOH solution, and detect the content of bacitracin by HPLC. The final concentration of bacitracin is 3.42 mg / mL, and the purity of bacitracin is 57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com