A construction method, engineering Escherichia coli and application of a shape-changing engineering Escherichia coli

A technology of Escherichia coli and construction method, which is applied to bacteria, introduction of foreign genetic material using vectors, fermentation, etc., can solve the problems of cell shape transformation, low product yield, and high solvent consumption, and achieves inhibition of cell division and improved economy. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

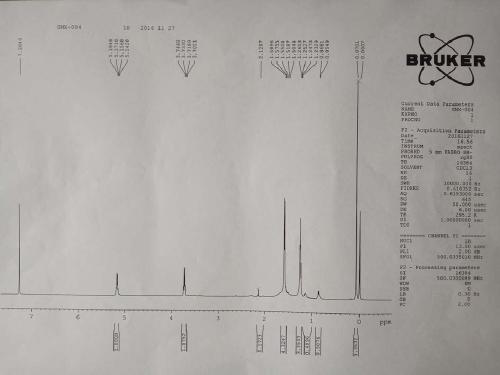

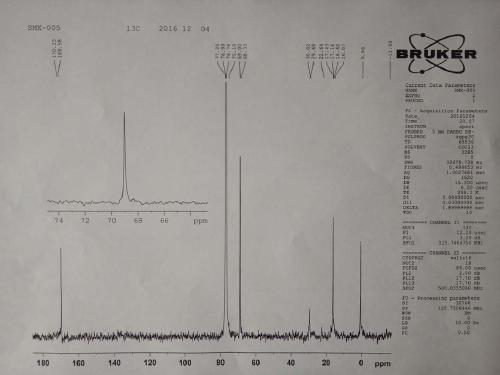

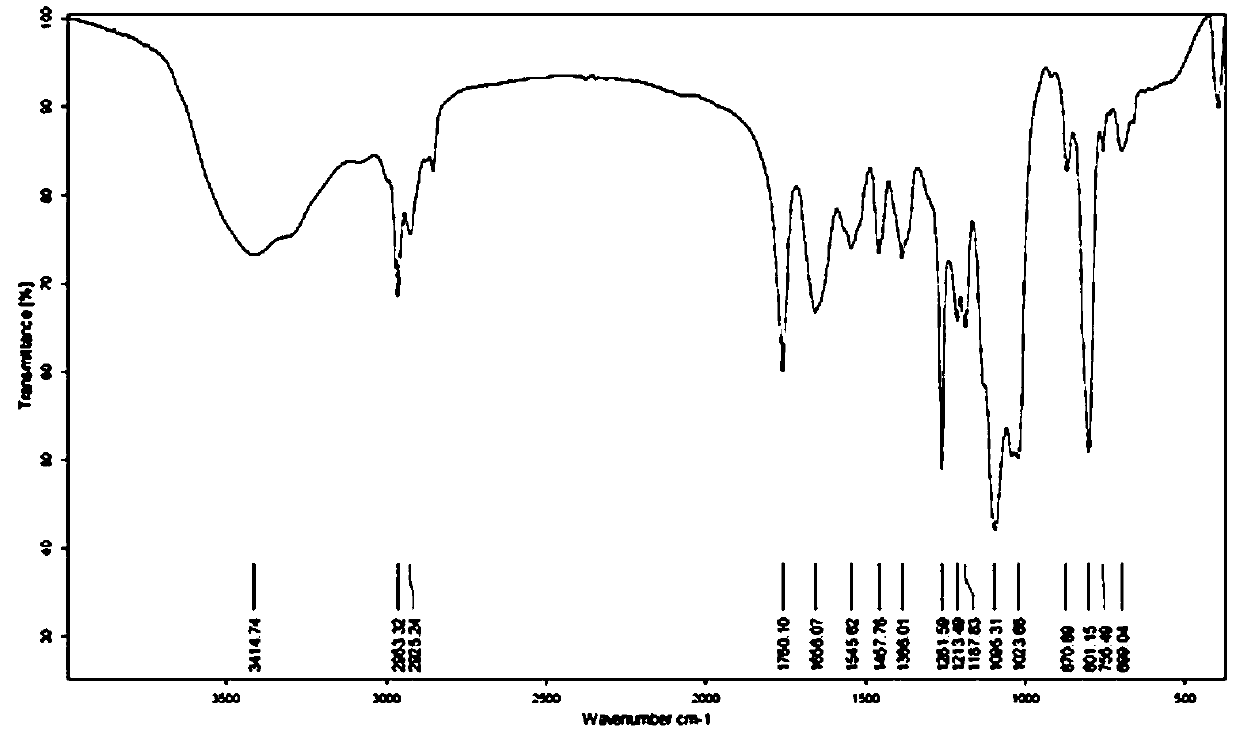

[0023] Step 1) Construction of an expression vector containing exogenous propionyl-CoA transferase (PCT) gene and PHA synthetase gene.

[0024] According to the published propionyl-CoA transferase (PCT) gene of Clostridum propionicum (Choi SY et al., 2016 Nature Biotechnology, 34(4):435-442) and Pseudomonas sp. ) The full-length sequence information of the PHA synthase gene (Yang TH et al., 2011 Appl Microbiol Biotechnol, 90:603-614) of MBEL 6-19, the two sequences are optimized to be suitable for expression in Escherichia coli, After optimization, PCTcp (sequence is SEQ ID NO: 1) and PHApse (sequence is SEQ ID NO: 2) are obtained.

[0025] The chemical synthesis is carried out according to PHApse, and the sequences of NdeI and XhoI enzyme cleavage sites are respectively added to the two ends of the sequence during synthesis. The universal expression plasmid PACYCDuet-1 and the synthetic linear DNA fragment were digested with NdeI and XhoI respectively and ligated into a new ...

Embodiment 2

[0034] The engineered Escherichia coli constructed in Example 1 was used to ferment and produce polylactic acid using glucose as a carbon source. The conditions for using this strain to ferment and produce polylactic acid are as follows: in a 1L fermentation system (Shanghai Bailun, 1L bioreactor), use 400mL liquid volume, inoculum size is 5%, fermentation temperature is 37°C, pH value is controlled at 6.95, medium The components are shown in Table 2. The initial glucose addition amount is 20g / L, the stirring speed is 300 to 600rap / min, the dissolved oxygen is controlled at a volume concentration of 10%-30%, and after 72 hours of fermentation, the culture solution is centrifuged to collect the bacteria. The bacterial cell pellet was washed once with ethanol, twice with distilled water, and then dried. Polylactic acid was extracted from the dried bacteria by Soxhlet extraction.

[0035] Table 2 Composition of experimental medium

[0036]

[0037] See Table 4 for the yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com