Small-capacitance power converter and power grid side electric energy quality control working method and bus voltage suppression control method thereof

A technology of power converter and DC bus voltage, applied in the direction of electronically commutated motor control, AC power input conversion to AC power output, motor control, etc., can solve motor torque fluctuations, restrict the application of small capacitor drive systems, and DC bus Solve problems such as voltage fluctuations, achieve the effect of reducing the voltage stress of power devices, realizing high-performance operation, and decoupling control of pulsation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the example of the present invention will be described in detail below in conjunction with the accompanying drawings and attached tables in the example of the present invention:

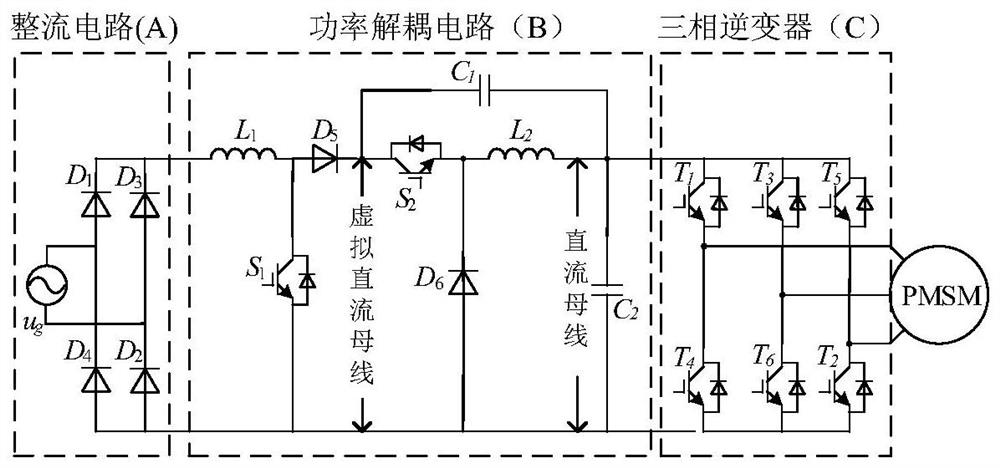

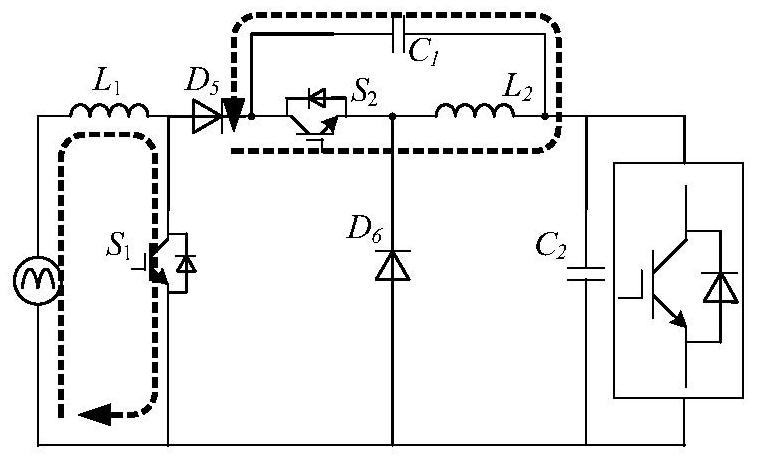

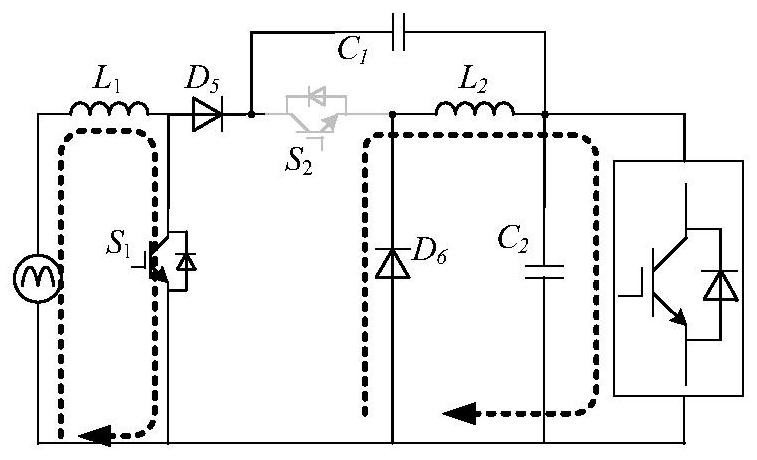

[0028] A novel small-capacitance power converter for a permanent magnet synchronous motor drive system of the present invention includes a diode rectifier, a novel active power decoupling circuit and a motor three-phase inverter. Construct an active power decoupling circuit based on small-capacity film capacitors with dual energy channels, which controls the active power decoupling circuit to absorb and release grid pulsating power according to the difference between grid power and motor power, and greatly improves the flexibility of dealing with pulsating power. After it replaces the traditional large-capacity electrolytic capacitor, it can effectively eliminate the disadvantages of the traditional drive system such as poor reliability and short life, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com