Molybdenum disulfide modified schwertmannite and preparation method and application thereof

A molybdenum disulfide and Schwitt technology, which is applied in the field of molybdenum disulfide modified Schwietermanite to efficiently degrade roxarsine in water, can solve the problem that organic pollutants cannot be fully degraded, and achieve the effect of rapid and efficient degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

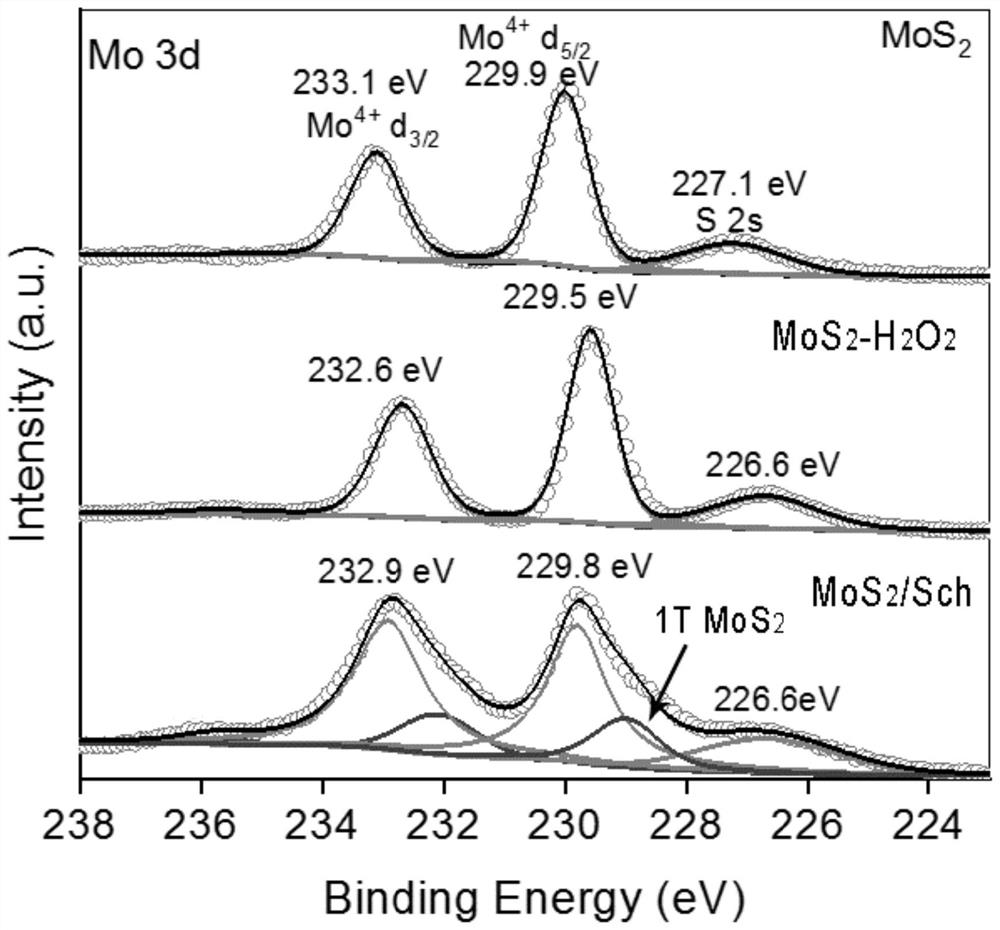

[0046] Molybdenum disulfide modified Schwittmannite (MoS 2 / Sch) preparation:

[0047] First to 74mmol Fe 2+ Add 37mmol H to the aqueous solution 2 o 2 (Fe 2+ with H 2 o 2 Molar ratio is 2), reacted for 1 hour. Then add 3mmol MoS 2 After stirring for 15 hours, the product was collected by filtration with 0.45 μm filter paper and washed 4 times with acidic water and pure water to obtain the solid catalyst MoS 2 / Sch, samples were preserved after vacuum freeze-drying.

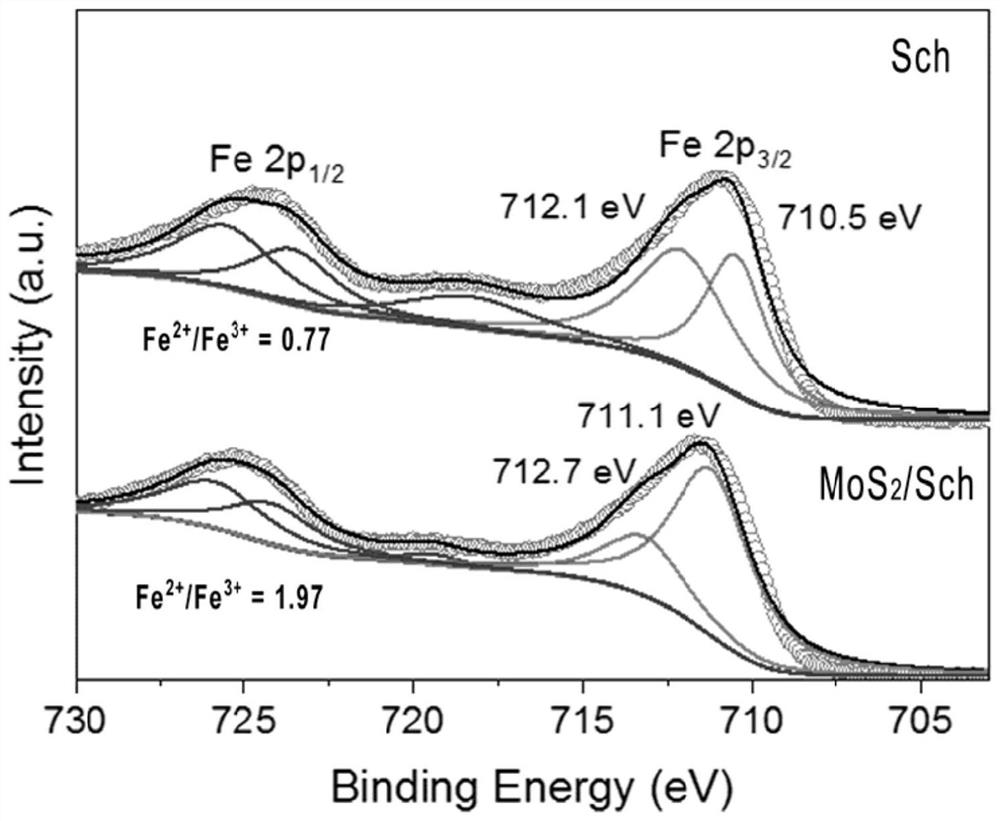

[0048] The 1.3g of MoS prepared in this example 2 / Sch, Fe 2+ amount and Fe 3+ The amount is determined by XPS, and the mass ratio of the two is 1.97.

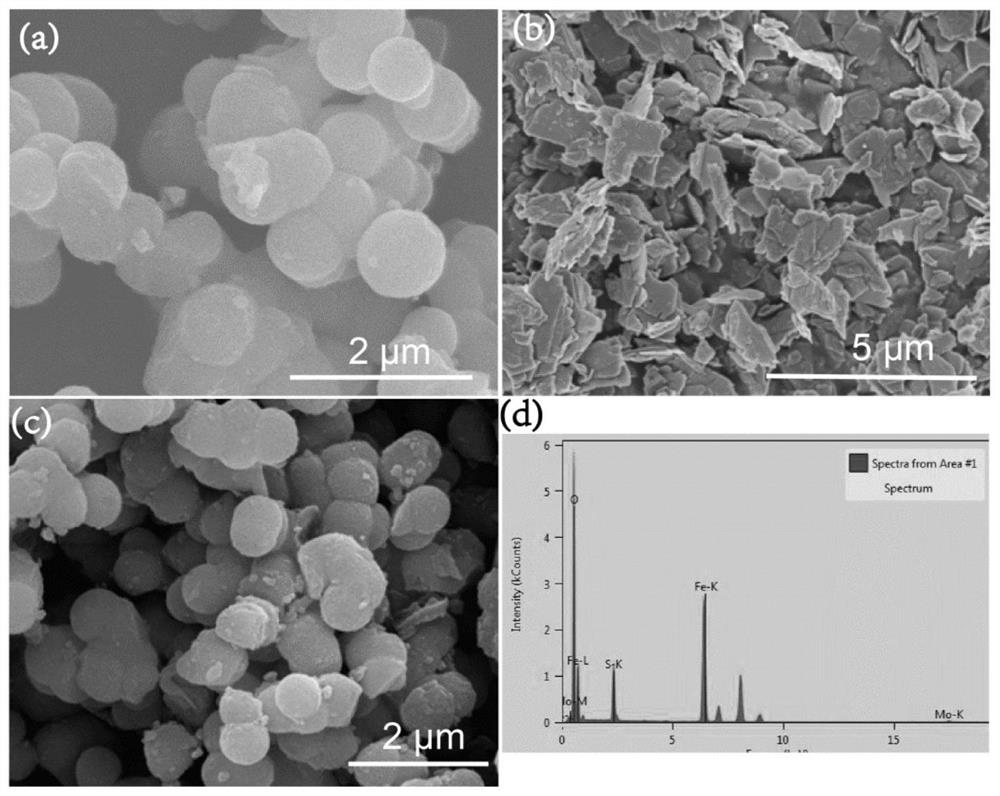

[0049] Seen from SEM ( figure 1 ), pure MoS 2 is a flaky structure ( figure 1 a), Sch is the appearance of the ball ( figure 1 b), MoS 2 / Sch shows a smaller size than Sch (average particle size 500-600nm), and small pieces of particles are loaded on Schwittmannite ( figure 1 c). In addition, the EDS plot ( figure 1 d) Display MoS 2 Modified ...

Embodiment 2

[0051] Molybdenum disulfide modified Schwittmannite (MoS 2 / Sch) preparation:

[0052] First to 100mmol Fe 2+ Add 50mmol H to the aqueous solution 2 o 2 (Fe 2+ with H 2 o 2 Molar ratio is 2), reacted for 1 hour. Then add 4.1mmol MoS 2 After stirring for 15 hours, the product was collected by filtration with a 0.45 μm filter membrane (filterable), and washed 4 times with acidic water and pure water to obtain a solid catalyst MoS 2 / Sch, samples were preserved after vacuum freeze-drying.

[0053] The 1.4g MoS prepared in this example 2 / Sch, Fe 2+ amount and Fe 3+ The amount is determined by XPS, and the mass ratio of the two is 1.92.

Embodiment 3

[0055] Molybdenum disulfide modified Schwittmannite (MoS 2 / Sch) preparation:

[0056] First to 120mmol Fe 2+ Add 60mmol H to the aqueous solution 2 o 2 (Fe 2+ with H 2 o 2 Molar ratio is 2), reacted for 1 hour. Then add 5mmol MoS 2 After stirring for 15 hours, the product was collected by filtration with a 0.45 μm filter membrane and washed 4 times with acidic water and pure water to obtain the solid catalyst MoS 2 / Sch, samples were preserved after vacuum freeze-drying.

[0057] The 1.51g of MoS prepared in this example 2 / Sch, Fe 2+ amount and Fe 3+ The amount is determined by XPS, and the mass ratio of the two is 1.94.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com