Method for deeply removing sodium and potassium elements in high-purity arsenic oxide

A technique for oxidizing arsenic and sodium, which is applied in chemical instruments and methods, arsenic oxide/arsenic hydroxide/oxyacid arsenic, arsenic compounds, etc. It can solve problems such as difficult stability, high impurity elements, and inability to replace imports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

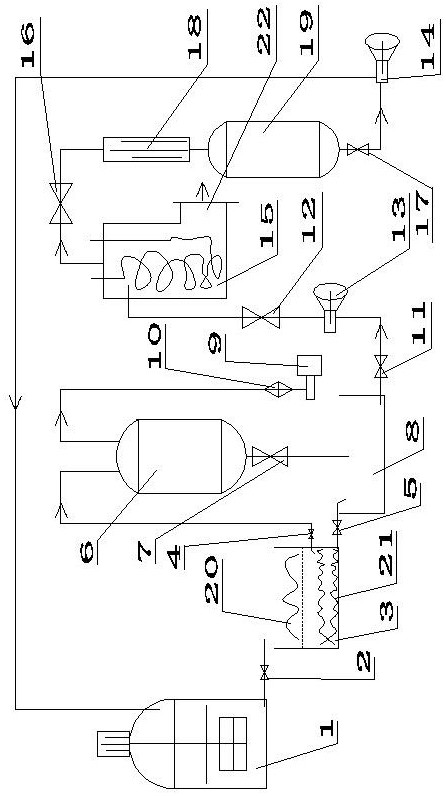

[0014] Combine below figure 1 The present invention is further described.

[0015] The processing object of this process is high-temperature oxidation of crude arsenic and multiple distillation purification to obtain high-purity arsenic oxide (mostly diarsenic trioxide and a very small amount of diarsenic pentoxide) containing 20ppb-30ppb of potassium and sodium respectively.

[0016] 1. Equipment description:

[0017] The washing mixing tank 1 is connected to the suction filter tank 3 through the discharge valve 2, under the action of the vacuum pump 9 and the vacuum control valve 10, the vacuum bag 6 forms a negative pressure, the suction filter valve 10 is opened, and the upper filter cake 20 is obtained by suction filtration. With the lower layer filtrate 21, the lower layer filtrate 21 enters the turnover lotion tank 8 through the liquid discharge valve 5 and the liquid flowing out from the discharge valve 7, opens the control valve 11, the control valve 12 and the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com