Preparation method of dual-element Pt/PdPt/Pt sandwich tube wall porous nanotube and porous nanotube

A technology of nanotubes and tube walls, which is applied in the field of preparation of bimetallic layered porous structure nanotubes, can solve the problems of insignificant improvement in catalyst stability and decrease in mass specific activity, so as to improve activity, improve utilization rate, and reduce usage volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a porous nanotube with a tube wall of a Pt / PdPt / Pt sandwich structure, comprising the following steps:

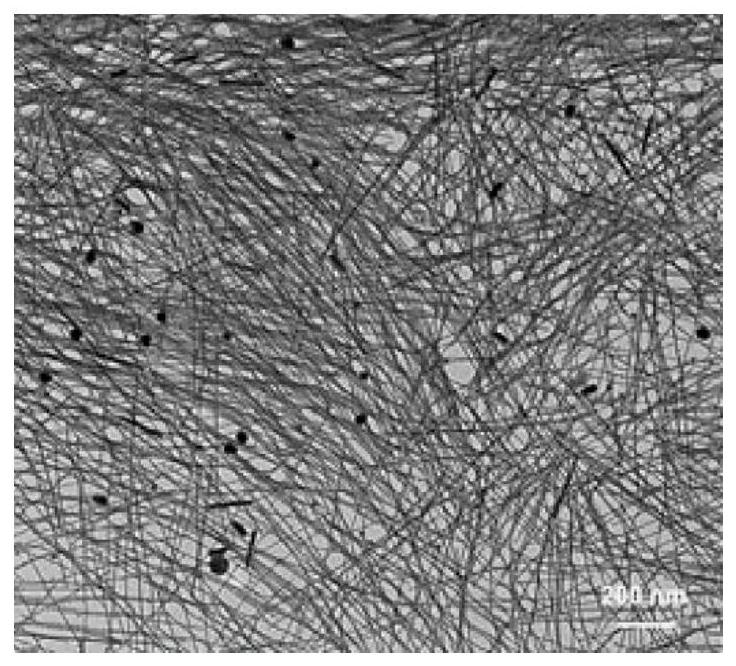

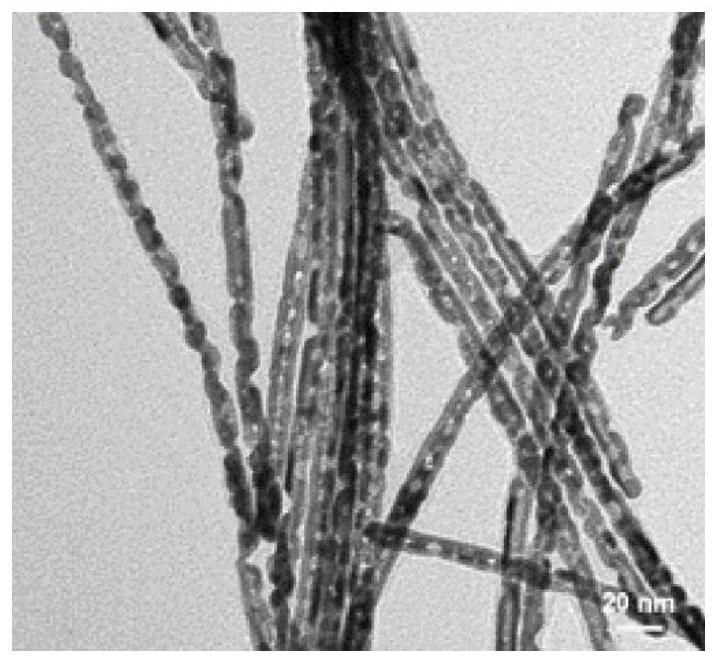

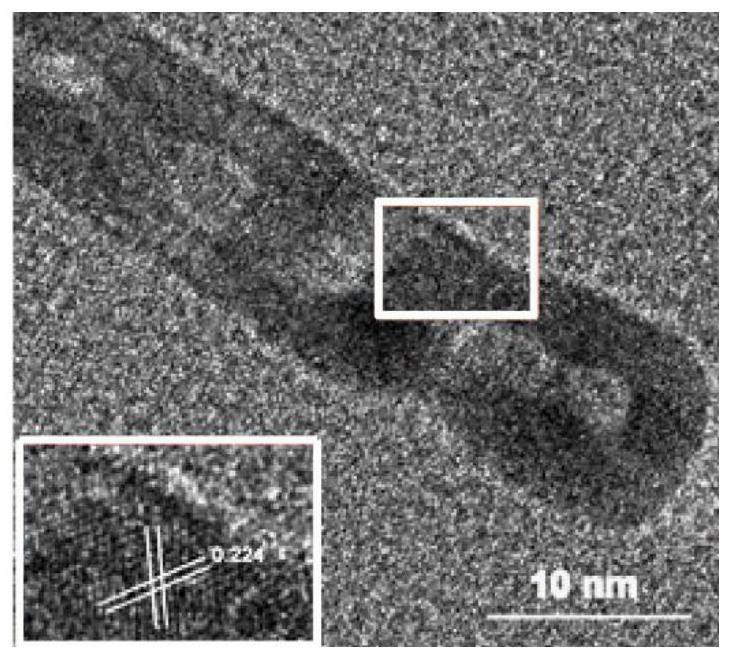

[0025] S1. The procedure of utilizing the Kirkendall effect to form PdPt nanotubes: Pd nanowire powder, polyvinylpyrrolidone (PVP), NaI, ascorbic acid (hereinafter also referred to as AA) and chloroplatinic acid (H 2 PtCl 6 ) dissolved in an organic solvent, mixed and stirred at 180-290°C for 1-2 hours to prepare PdPt nanotube powder,

[0026] S2. Tube wall etching process: disperse the PdPt nanotube powder obtained in step S1 in water and heat it to 45-60°C, add hole etching solution dropwise therein, react for 10-60min, and filter to obtain a tube wall with a rough porous surface. Porous nanotubes with Pt / PdPt / Pt sandwich structure, in which the pore etching solution contains FeCl 3 , NaI, PVP, HCl components.

[0027] In the S1 step of the present invention, mainly using Pd nanowires with a diameter as the substrate...

Embodiment 1

[0049] Mix and disperse 200mg of PVP (polyvinylpyrrolidine provided by Tianjin Kemiou, molecular weight 1-130W), 100mg of NaI, 15mg of AA, and 3mg of Pd nanowire powder in 15mL of ethylene glycol, ultrasonically for 20min and place in 50mL In the flask, preheat with magnetic stirring in an oil bath at 90°C for 20 minutes, then raise the temperature of the oil bath to 190°C at a rate of 1°C / min, during which time 3 mL of 0.1 mM / L H 2 PtCl 6 The ethylene glycol solution was slowly added into the reaction flask, and kept heating and stirring at 190°C for 1-2 hours. After the reaction was completed, the reactant was centrifuged at 5000 r / min for 10 min after the temperature was lowered to room temperature, washed twice with ethanol, and finally dried in a blast drying oven at 70° C. to obtain PdPt bimetallic nanotube powder.

[0050] Take 2 mg of the nanotube powder prepared in the above step (1) and disperse it in 3 mL of purified water and preheat it in a water bath at 50 °C fo...

Embodiment 2

[0053] Mix and disperse 350mg of PVP (polyvinylpyrrolidine provided by Tianjin Kemiou, molecular weight 1-130W), 200mg of NaI, 25mg of AA, and 4mg of Pd nanowire powder in 20mL of ethylene glycol, ultrasonically for 25min and place in 50mL In the flask, preheat with magnetic stirring in an oil bath at 110°C for 20 minutes, then raise the temperature of the oil bath to 200°C at a rate of 1°C / min, during which time 4mL of 0.1mM / L H 2 PtCl 6 Ethylene glycol solution was slowly added into the reaction flask, and kept heating and stirring at 200°C for 1.5h. After the reaction was completed, the reactant was centrifuged at 6500 r / min for 10 min after the temperature was lowered to room temperature, washed twice with ethanol, and finally dried in a blast drying oven at 70° C. to obtain PdPt bimetallic nanotube powder.

[0054] Take 4 mg of the nanotube powder prepared in the above step (1) and disperse it in 3-6 mL of pure water and preheat it in a water bath at 50 °C for 10 min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com